Structure for closing hole for hydraulic circuit

A hydraulic circuit and occlusion technology, which is applied in the direction of pressure vessels, gas/liquid distribution and storage, pipes/pipe joints/fittings, etc., can solve the problems of plug looseness, axial force disappearance, and small elastic deformation, so as to prevent leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the closing structure of the hydraulic circuit hole according to the present invention will be described in detail with reference to the drawings.

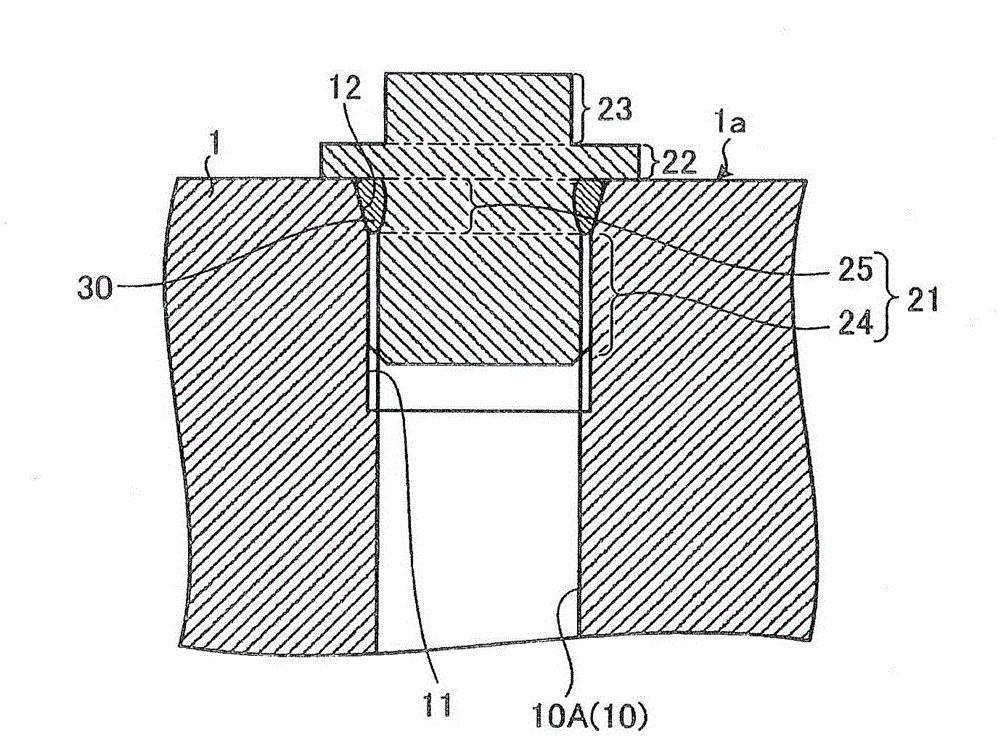

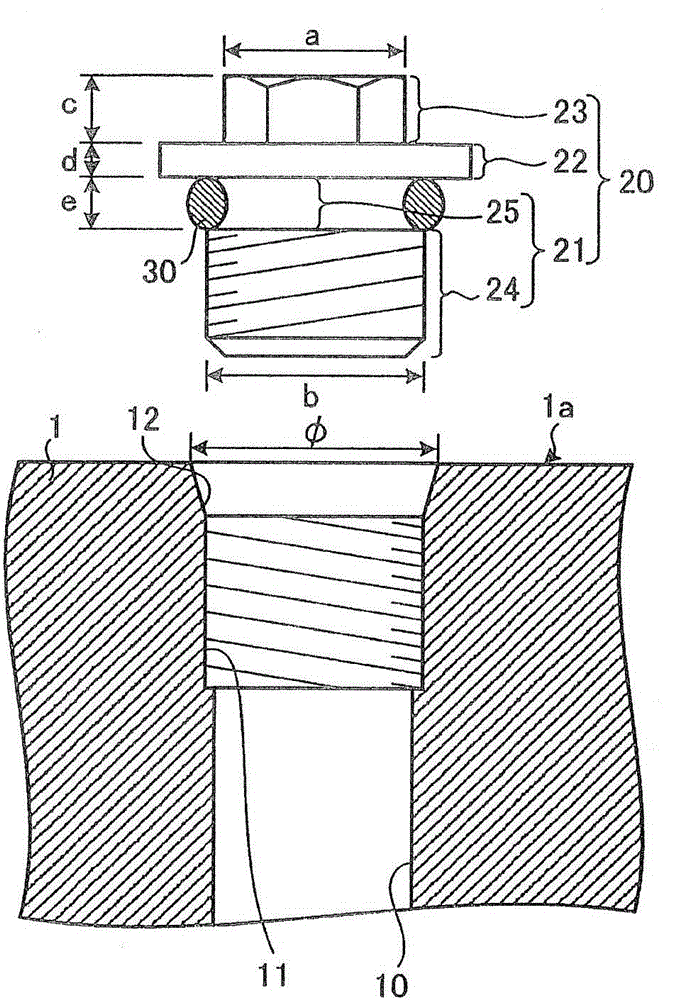

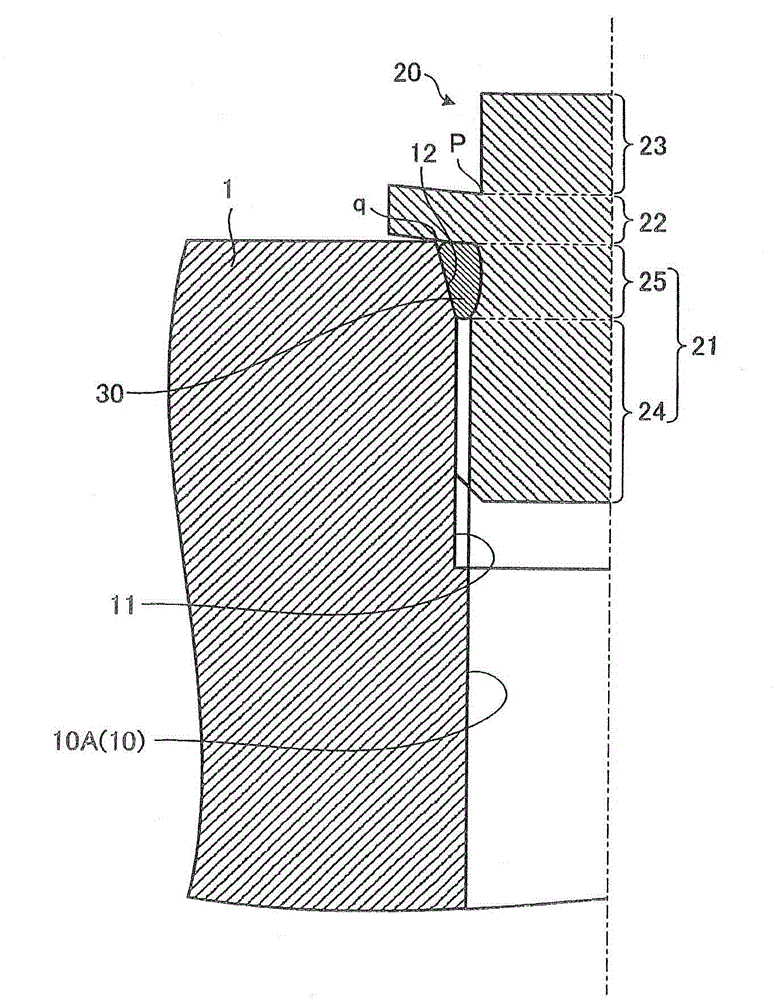

[0025] figure 1 It is a figure which shows the main part of the hydraulic equipment which applied the block structure of the hole for hydraulic circuits of embodiment of this invention. The hydraulic equipment exemplified here is an equipment in which the hydraulic circuit hole 10 is formed so as to open on the outer surface 1a of the main body 1, and the opening end of the hydraulic circuit hole 10 is closed by a plug 20, Thus, a hydraulic channel 10A is formed inside the main body 1.

[0026] Such as figure 1 as well as figure 2 As shown, the hydraulic circuit hole 10 of the main body 1 is provided with an internal thread portion 11 and a tapered portion 12. The female screw portion 11 is configured by providing a screw groove on the inner peripheral surface of the hydraulic circuit hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com