Front-back crossing jacquard elastic fabric with fireproof fabric layer

A fireproof fabric and elastic fabric technology, which is applied to the fabric of toys and the field of clothing, can solve the problems of not easy fabric elasticity, weak layering, and not long-lasting, and achieve the effect of easy elasticity, enhanced layering, and soft fabric.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

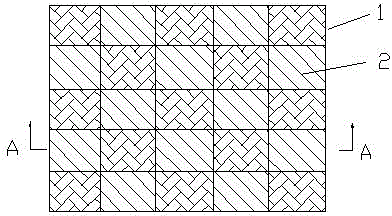

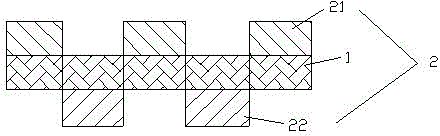

[0011] see figure 1 and figure 2 , The present invention relates to a front and back staggered jacquard elastic fabric with a fireproof fabric layer, comprising a base fabric 1, and the front and back sides of the base fabric 1 are provided with a jacquard layer 2 . The jacquard layer 2 includes several jacquard regions 21 and non-jacquard regions 22, and the jacquard regions 21 and non-jacquard regions 22 are block-shaped and arranged in a staggered manner. The jacquard regions 21 and non-jacquard regions 22 located on the front and back sides are distributed symmetrically in a staggered manner.

[0012] The base fabric 1 is made of fabric, the fabric is a warp knitted fabric, the laying yarn rule is 1-0 / 2-3, the veil is made of 75D / 36 T400 polyester fiber fully drawn filament, and the bottom yarn is made of FDY 84D / 36F polyester filament, the T400 polyester fiber fully drawn filament is hollow, and the cross section is cross-shaped. A fire-resistant fabric layer is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com