Auto-counting and safeguard component of punching machine

An automatic counting and safety protection technology, applied in safety equipment, metal processing, metal processing equipment, etc., can solve problems such as failure to proceed, photoelectric protection devices interfere with normal processing, etc., to reduce labor costs, promote production automation, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

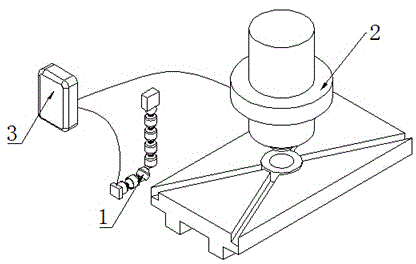

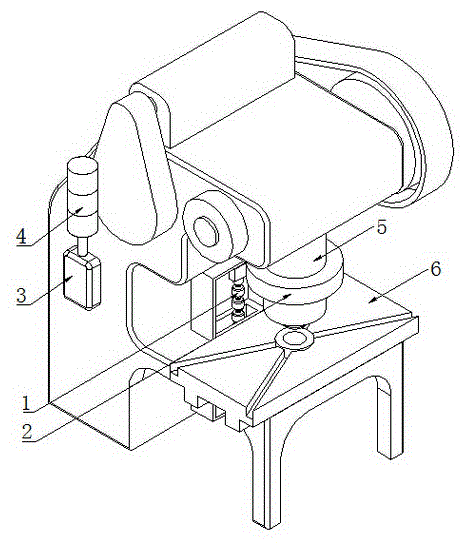

[0035] A kind of punch press automatic counting and safety protection assembly of this embodiment, such as figure 1As shown, it is mainly realized through the following technical solutions: a punch automatic counting and safety protection assembly, including an automatic counting device 1, a photoelectric protection device 2 and a control cabinet 3; the automatic counting device 1 includes a photoelectric proximity switch 11 and Flexible support 12, photoelectric proximity switch 11 is fixed on one end of flexible support 12; Described photoelectric protection device 2 comprises annular housing 21 and a plurality of photoelectric protection units 22 that are built in annular housing 21; The photoelectric protection unit 22 includes an infrared transmitter, an infrared receiver and a control circuit, and the infrared transmitter and the infrared receiver are arranged in the same direction and are all connected to the control circuit; the control cabinet 3 includes an independent...

Embodiment 2

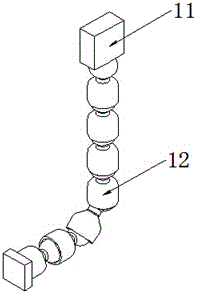

[0038] This embodiment is further optimized on the basis of the above embodiments, such as image 3 As shown, further, the flexible bracket 12 includes a plurality of universal joints connected in series; one end of the universal joints is spherical, and the other end is conical. Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

Embodiment 3

[0040] This embodiment is further optimized on the basis of the above embodiments, and further includes an alarm device 4 connected in series with a plurality of parallel relays. Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com