Mold for molded barb type side bending

A technology of barbs and moulds, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of poor product consistency, high manufacturing cost, easy-to-draw materials, etc., and achieve high shape consistency, simple structure, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

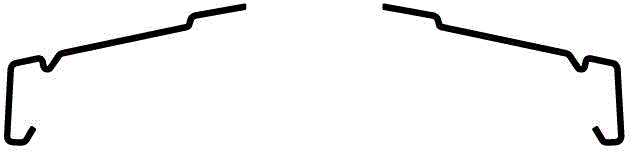

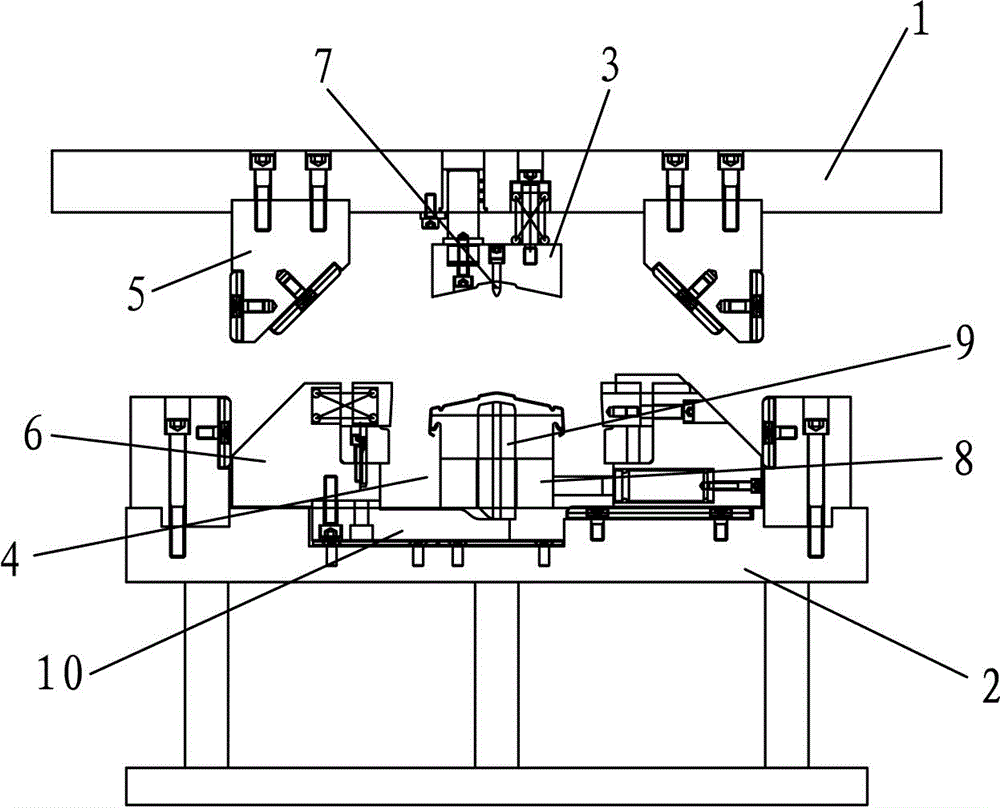

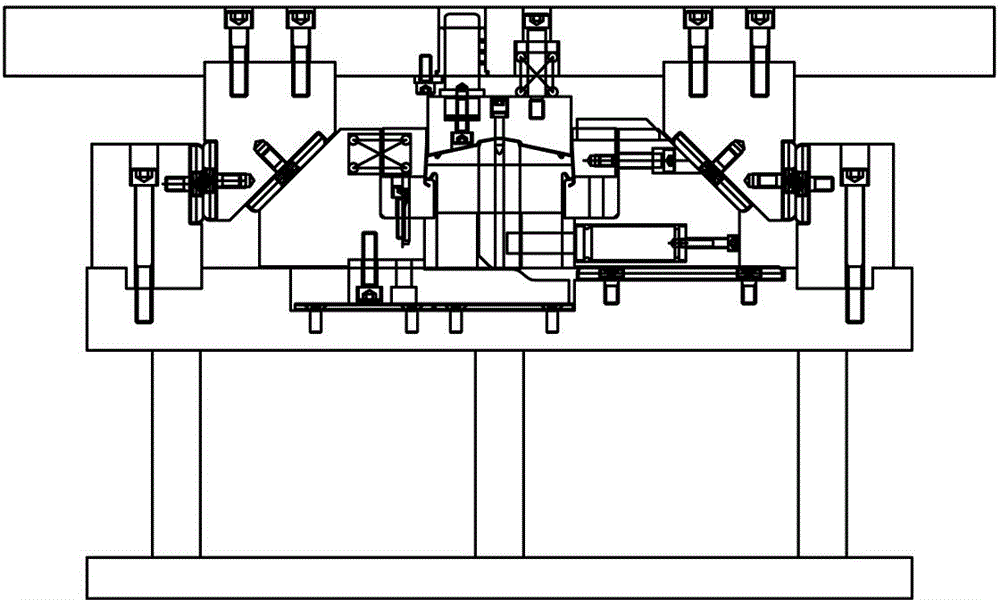

[0033] Such as Figure 2-3 As shown, the present invention includes an upper mold 1, a lower mold 2, an upper mold fixed forming block 3, a lower mold fixed forming block 4, an inserting knife 5, and a side forming block 6.

[0034] The upper mold 1 and the lower mold 2 are connected and coordinated through several positioning guide pillars and several springs;

[0035] The fixed forming block 3 of the upper mold is fixed on the upper mold 1;

[0036] The lower mold fixed forming block 4 is fixed on the lower mold 2;

[0037] Both sides of the upper mold fixed forming block 3 are respectively provided with a slotting knife 5;

[0038] Both sides of the fixed molding block 4 of the lower mold are respectively provided with a side molding block 6 through the guide rail and the return spring on the lower mold 2;

[0039] The side forming block 6 cooperates with the side of the fixed forming block 4 of the lower mold to form a barb forming cavity to realize barb bending process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com