Machine tool set used for machining rollers in batches

A batch processing and machine tool technology, applied in the field of machine tools, can solve the problems of low working efficiency of machine tools and special maintenance of fixed tables, so as to save costs, realize mass production and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

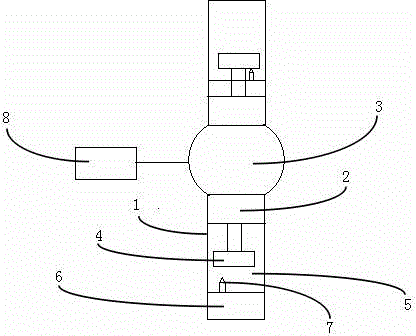

[0017] as attached figure 1 As shown, a machine tool group for batch processing rolls includes two machine tools 1, and the back contact frame 2 of the two machine tools 1 is fixedly connected to the rotating shaft 3 arranged between the two machine tools 1, and the two machine tools 1 The back contact frame 2 of the machine tool 1 is provided with a chuck 4 for fixing the workpiece. The positions where the chucks 4 of the two machine tools 1 protrude are the same, and the workbenches 5 of the two machine tools 1 are also provided with a fixing seat 6. Wherein the fixed seat 6 of one machine tool 1 is arranged on the outer side of the circle with the chucks 4 of two machine tools 1 as the diameter, and the fixed seat 6 of another machine tool 1 is arranged on the outer side of the circle with the chucks 4 of the two machine tools 1 as the diameter. On the inner side of the circle, the two fixed seats 6 are provided with a drill bit 7 facing the chuck 4 and the two machine tool...

Embodiment 2

[0020] A machine tool group for batch processing rolls, including four machine tools 1, the angle between two of the four machine tools 1 is 90°, and the back contact frames 2 of the four machine tools 1 are all connected to the four machine tools 1. The rotating shaft 3 is fixedly connected, and the contact frame 2 on the back of the four machine tools 1 is provided with a chuck 4 for fixing the workpiece. The positions where the chucks 4 of the four machine tools 1 protrude are the same. 5 are also provided with fixed seats 6, wherein the fixed seats 6 of the two machine tools 1 are arranged on the outside of the circle with the chucks 4 of the four machine tools 1 as the diameter, and the fixed seats 6 of the other two machine tools 1 are arranged on four The chuck 4 of the machine tool 1 is the inner side of the circle of the diameter, and the drill bits 7 facing the chuck 4 are all provided on the four fixed seats 6 . The rotating shaft 3 is fixedly connected with the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com