Rotary workbench for hydraulic press

A technology of rotary workbench and workbench, applied in the direction of presses, manufacturing tools, etc., can solve the problems of short service life of workbench, waste of time and resources, time-consuming and labor-intensive, etc., and achieve the effect of not easy to wear and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

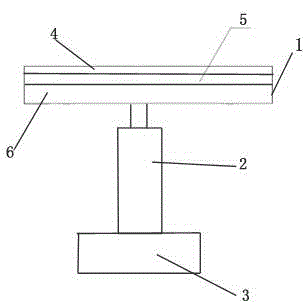

[0010] Such as figure 1 As shown, the present invention provides a rotary workbench for a hydraulic machine, which includes a workbench body 1, a rotating pillar 2 connected to the bottom of the workbench body 1, and a support block 3 connected to the bottom of the rotating pillar 2; the workbench body It is a three-layer structure, which is PE protective layer 4, aluminum-copper composite layer 5 and steel plate layer 6 from top to bottom.

[0011] Wherein, the thickness of the PE protective layer is 2-4mm, which protects the backing plate and is not easy to wear and deform; the thickness of the steel plate is 4-8cm. For those skilled in the art, equivalent replacements or changes can be made according to the technical solution of the present invention and its inventive concept, and all these changes or replacements should fall within the protection scope of the appended claims of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com