Fixture positioning device for electronic fuel injection throttle valve assembly mark printing

The technology of a fixture positioning device and an EFI throttle, which is applied in printing, typewriter and other directions, can solve the problems of affecting work efficiency, time-consuming and labor-intensive, etc., and achieve the effects of improving production efficiency, reducing production cost and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

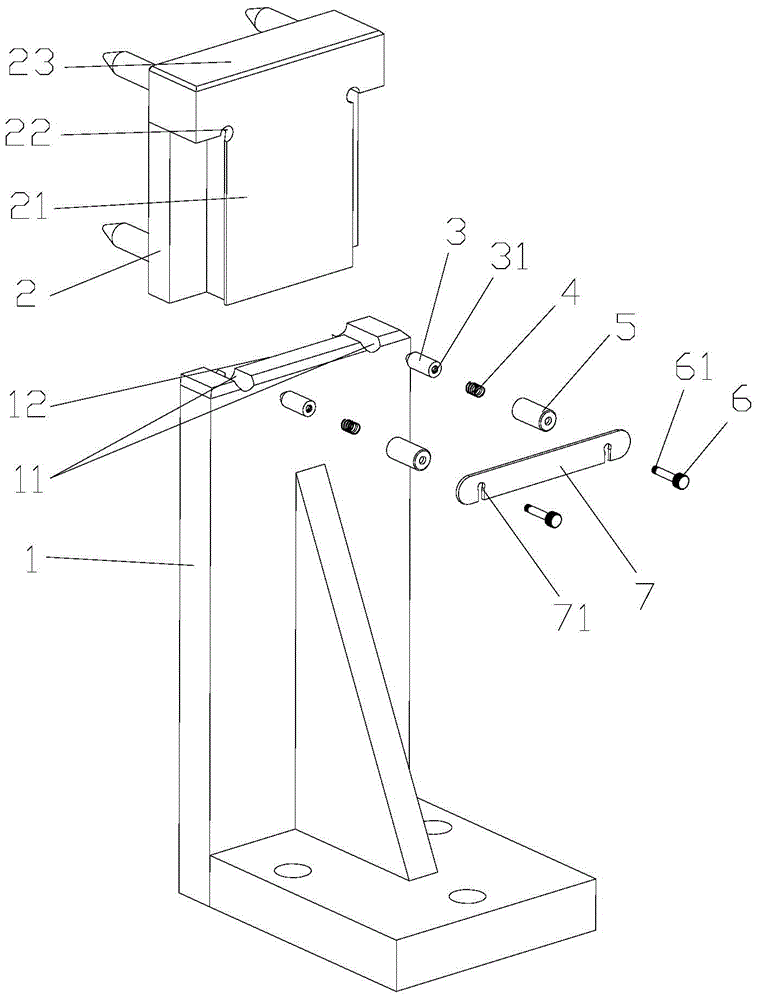

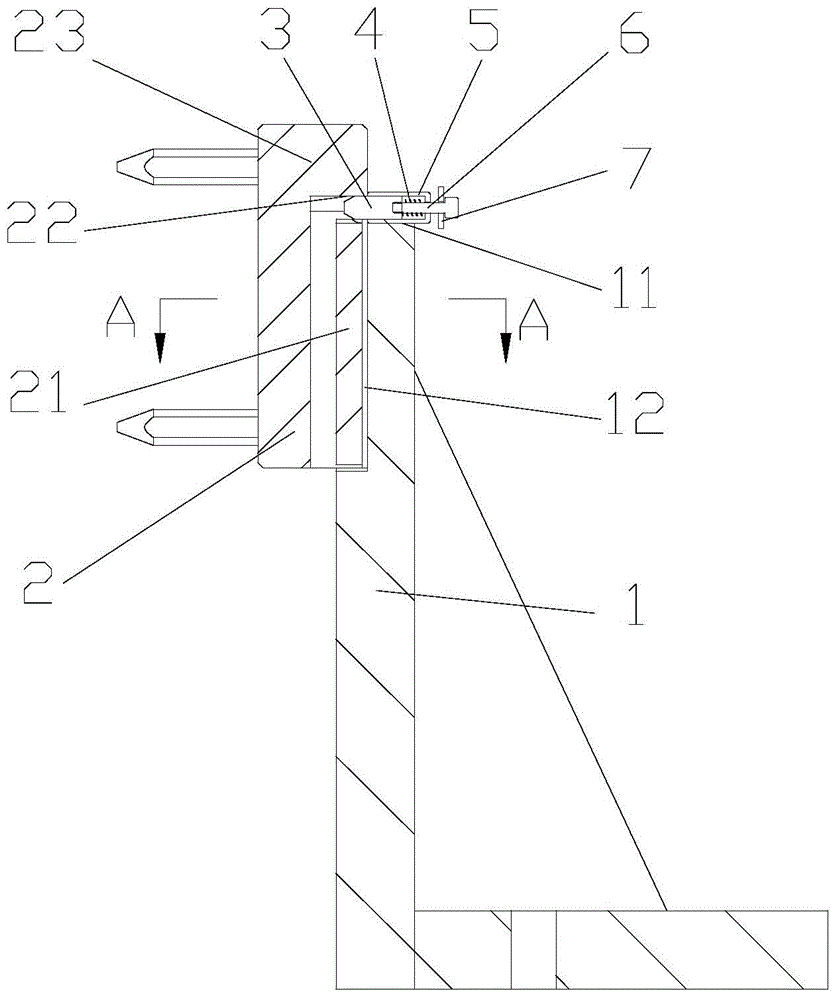

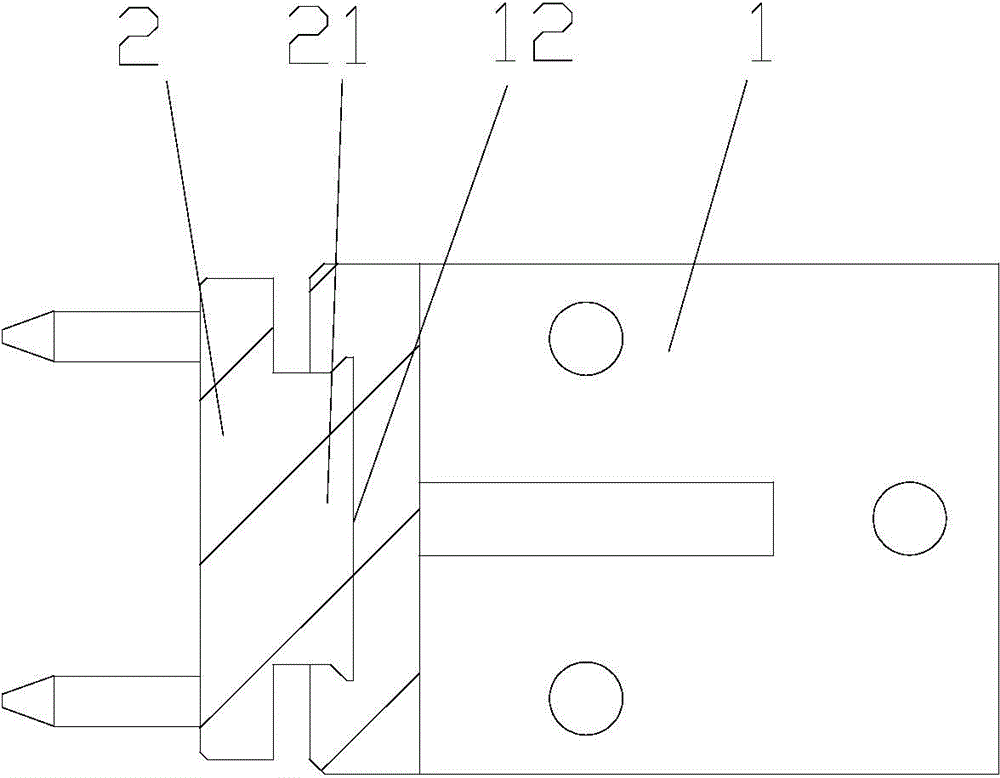

[0013] Attached below Figure 1-3 An embodiment of the present invention is described.

[0014] A fixture positioning device for marking printing of an EFI throttle assembly has a dedicated base 1 and a fixture body 2. The upper end of the dedicated base 1 is provided with an arc-shaped groove 11, and the arc-shaped groove 11 is fixedly provided There is a spring knob body, the connecting rod 7 is connected to the spring knob body through a U-shaped hole 71, a dovetail groove 12 is provided on one side of the special base 1, and a dovetail boss 21 is provided on one side of the clamp body 2. The boss 21 and the dovetail groove 12 are fitted together, and the special base 1 and the fixture body 2 are fixedly connected by the limit stop 23 on the clamp body 2 and the upper end surface of the special base 1 to limit the position. The stopper 23 can adjust the height of the clamp body 2. One end of the spring knob body is sleeved with the limit hole 22 provided on the clamp body 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com