clay coin making process

A technology for making clay coins, which is applied in the field of clay coin making, can solve the problems of simple appearance, easy air-drying and cracking, poor mechanical properties of clay coins, etc., and achieve the effect of beautiful appearance, low cost and realistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

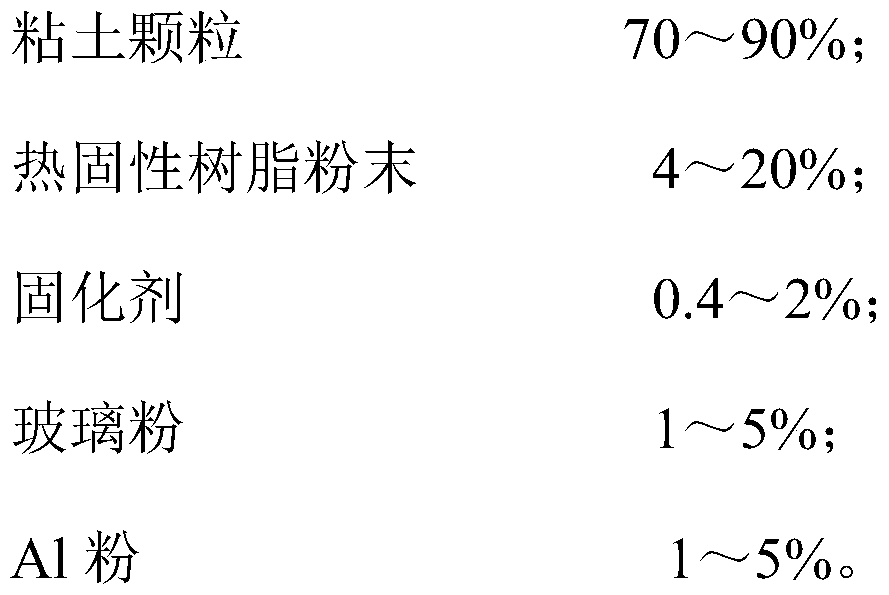

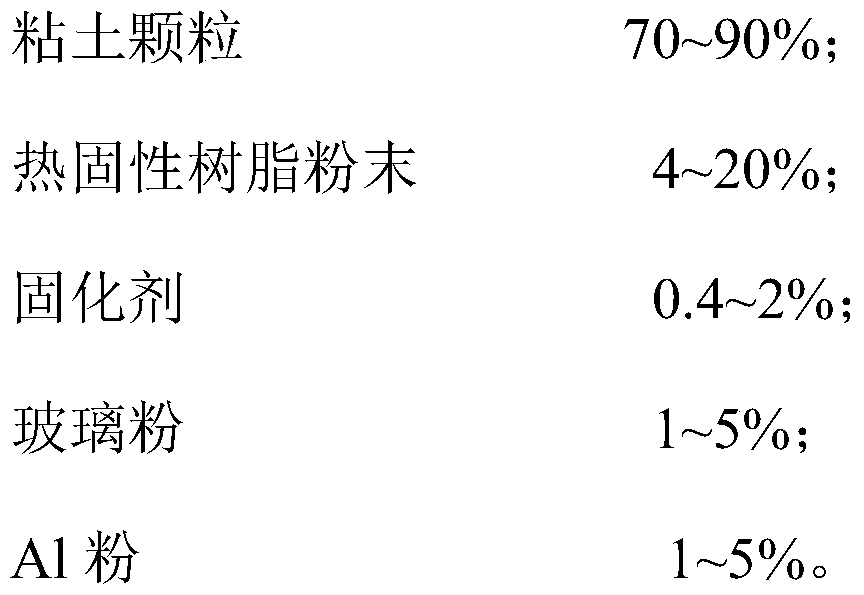

Method used

Image

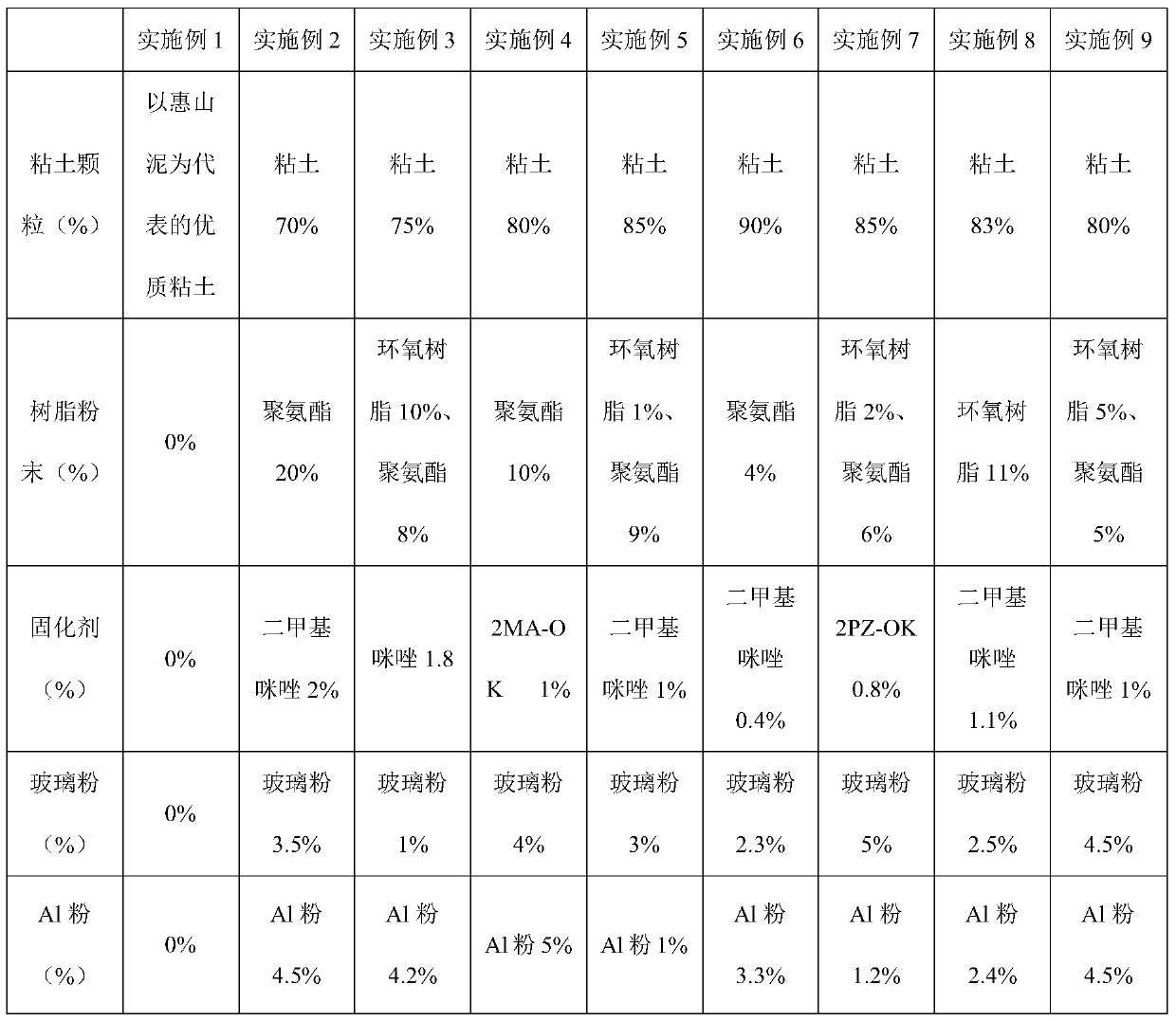

Examples

Embodiment 1

[0038] Example 1-3: The clay is pulverized to 120 mesh, 300 mesh and 350 mesh, the humidity is controlled at 6%, the clay powder after humidification is molded, and the molding pressure is 30MPa, 10MPa, 20MPa, and it is dried in the shade, air-dried and sun-dried respectively , after standing for a period of time, no dust appeared, and then according to the process steps, the mud was coated with 100 μm transparent self-crosslinking acrylic resin, water-soluble amino resin and self-drying alkyd resin, and then coated with carbon powder after the film was dry The mixture with the acrylic resin mass ratio of 1:3 was tested, and it was found that Huishan mud in Example 1 was soaked under a certain pressure for 72 hours without obvious leakage; the water-soluble amino resin used in Example 2 has good stability and chemical resistance. Corrosive, can withstand frequent water immersion tests without leakage; the self-drying alkyd resin selected in Example 3 has excellent adhesion and ...

Embodiment 4

[0039] Example 4-5: A clay material with a mesh number of 150 and a plasticity of 4.0 was used, the humidity was controlled at 12%, and the molding pressure was increased to 40 MPa. After the mud was demoulded and dried in the shade, there were no visible cracks, and no cracks appeared after being placed for a period of time. dust. According to the process steps, the mud base is coated with 90 μm water-soluble polyurethane resin / isocyanate and common acrylic resin respectively, and after the film is dry, the mixture of carbon powder and water-soluble polyurethane resin mass ratio is 10:1. It is found that the mixture of embodiment 4 After the water-soluble polyurethane resin is cured, the surface is relatively soft and easy to scratch, which is not conducive to operation, and there is a slight leakage phenomenon when scrubbing with water; in Example 5, the surface of the clay coin is frequently scrubbed with water, and leakage occurs, indicating that ordinary water-soluble acry...

Embodiment 6-7

[0040] Embodiment 6-7: Adopt the clay material that mesh number is 150, plasticity is respectively 6.0 and 7.0, and molding pressure is 30MPa, and moisture content is respectively 16% and 20%, and humidity is too big, and operability is not good, and mud pattern It was not clear before, it was not firm enough after demoulding, and there were slight cracks after drying in the shade. According to the process steps, the surface is coated with a self-crosslinking acrylic resin waterproof coating. After the film is dry, it is coated with a mixture of carbon powder and water-soluble polyurethane resin with a mass ratio of 10:1. The test found that soaking for 72 hours under a certain pressure There is a slight leak, but the phenomenon is not particularly serious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com