Drainage device for cabin of yacht

A technology for drainage devices and cabins, which is applied to ships, transportation and packaging, and pipelines for emptying/ballasting, etc. It can solve problems such as forgetting to discharge, and achieve the effects of saving manufacturing costs, less material consumption, and fewer operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

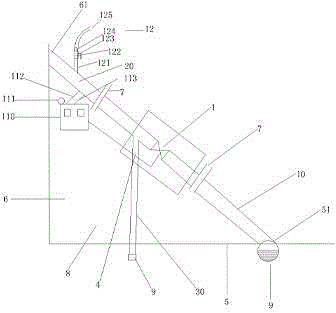

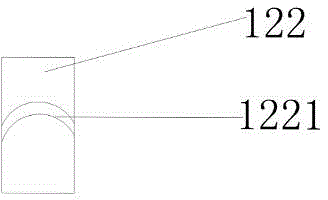

[0020] In order to better understand the improvement made by the present invention relative to the prior art, the specific implementation will be described in detail below, figure 1 A structural schematic diagram of a yacht cabin drainage device is shown. The water inlet pipe and the water outlet pipe connected to the inlet and outlet ends of the solenoid valve 1, and the water suction pipe 4 with one end connected to the water pipe but with a pipe diameter smaller than the water outlet pipe, one end of the water pipe leads to the water inlet 51 on the bilge plate, and one end of the water pipe leads to The bilge water discharge port 61 on the stern seal plate; the water suction pipe 4 leads to the bilge water, and the cabin drainage device also includes a drainage structure 12. The direction of the water outlet is obliquely arranged on one side of the water pipe 20 . The end of the ventilation steel pipe 121 away from the drain pipe is provided with an external thread, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com