A method of installing a tethering structure on an aircraft composite floor

A composite material and flooring technology, which is applied to aircraft parts, equipment for loading and unloading cargo, transportation and packaging, etc., can solve the problems of affecting the appearance, unreasonable reinforcement methods, etc., and achieve the effect of simple structure and fast installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

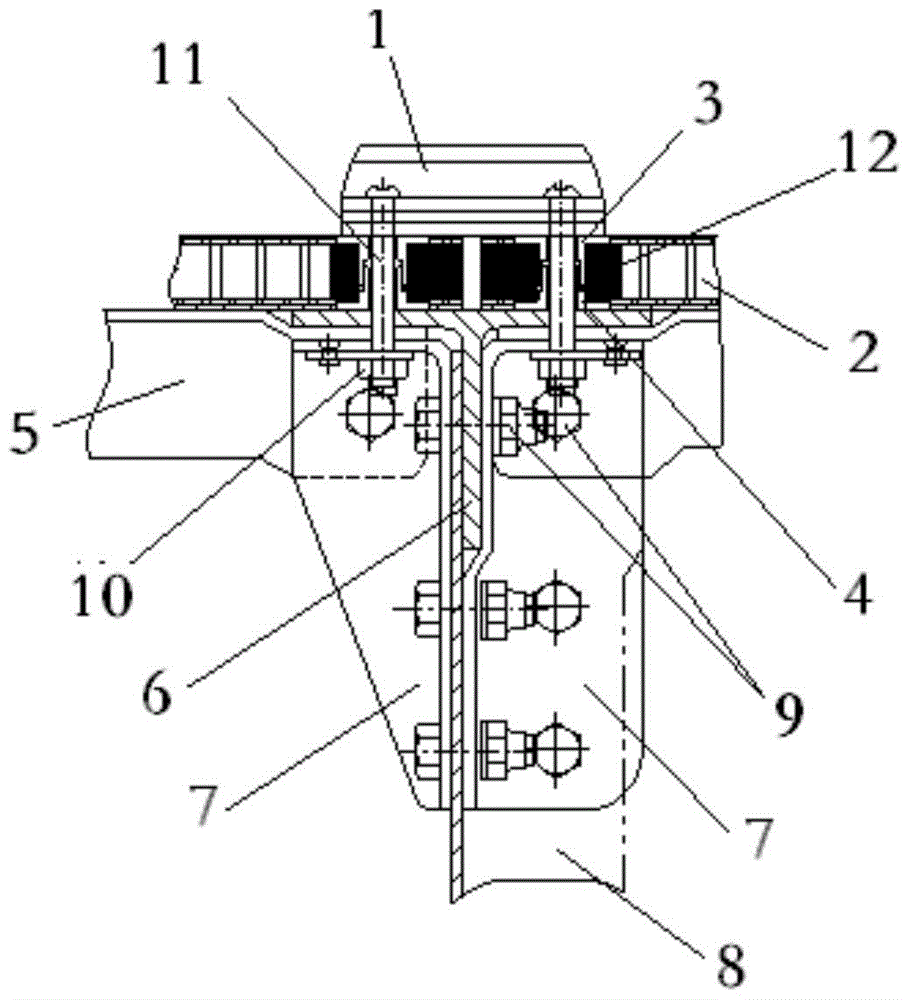

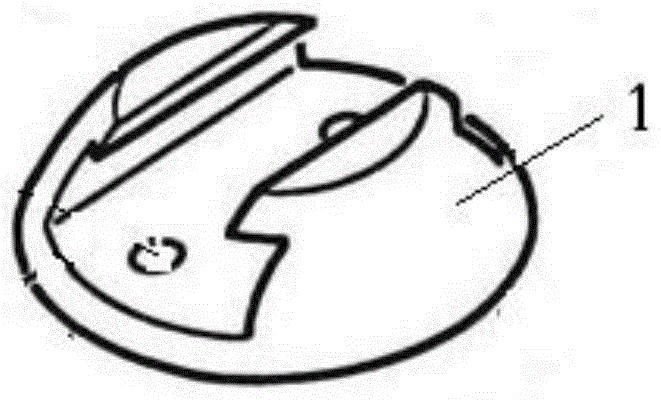

[0016] Referring to the accompanying drawings, the present embodiment is a schematic diagram of a method for installing a mooring structure on an aircraft composite floor. Bolts 11 can fix the mooring ring seat 1 with the composite material floor 2 , the longitudinal reinforcement 6 , the transverse reinforcement 5 and the reinforcement corner box 7 through the bracket nut 10 .

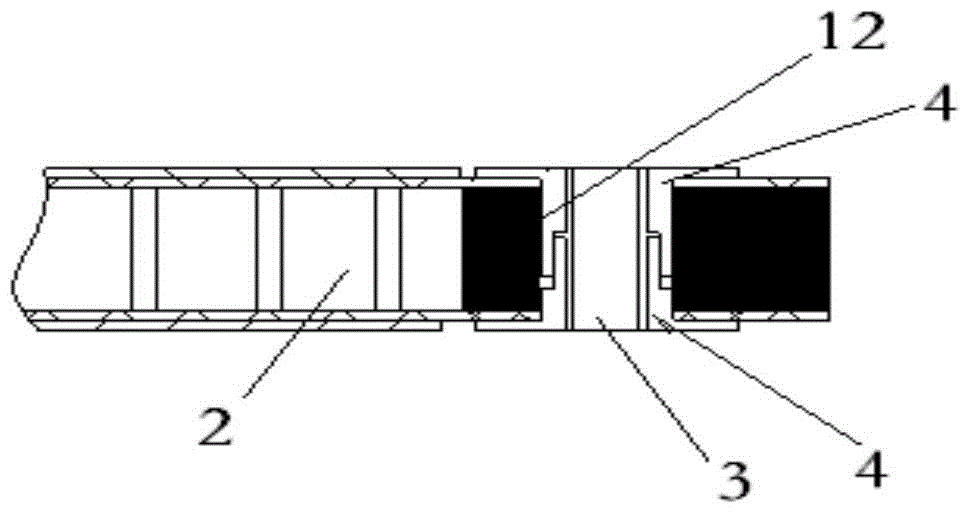

[0017] The composite material floor 2 is provided with an installation through hole 3. In order to protect the floor and enhance the strength of the installation through hole, it is best to protect and strengthen the installation hole during implementation. In this application, a protective hole bushing 4 is installed in the installation hole. In order to make the grommet liner fit closely with the mounting hole, epoxy sealant is coated around the mounting hole and bonded to the grommet liner 4 . Hole guard bushing 4 is respectively one up and down, supporting use.

[0018] In order to increase the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com