Circuit breaker housing automatic arrangement device

An automatic arrangement and circuit breaker technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that the upper and lower shells are mixed in one box, the stacking process is not very simple, and the labor intensity of operators increases, etc., to achieve a simple structure , improve safety, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

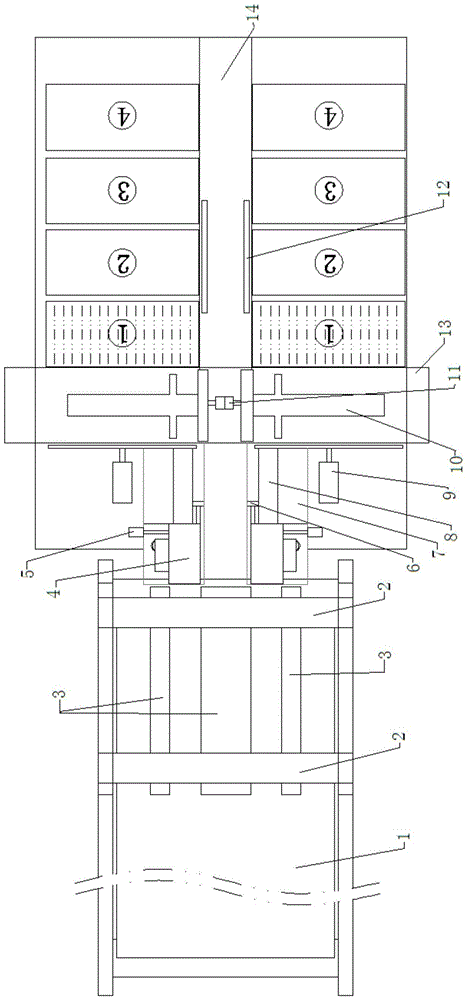

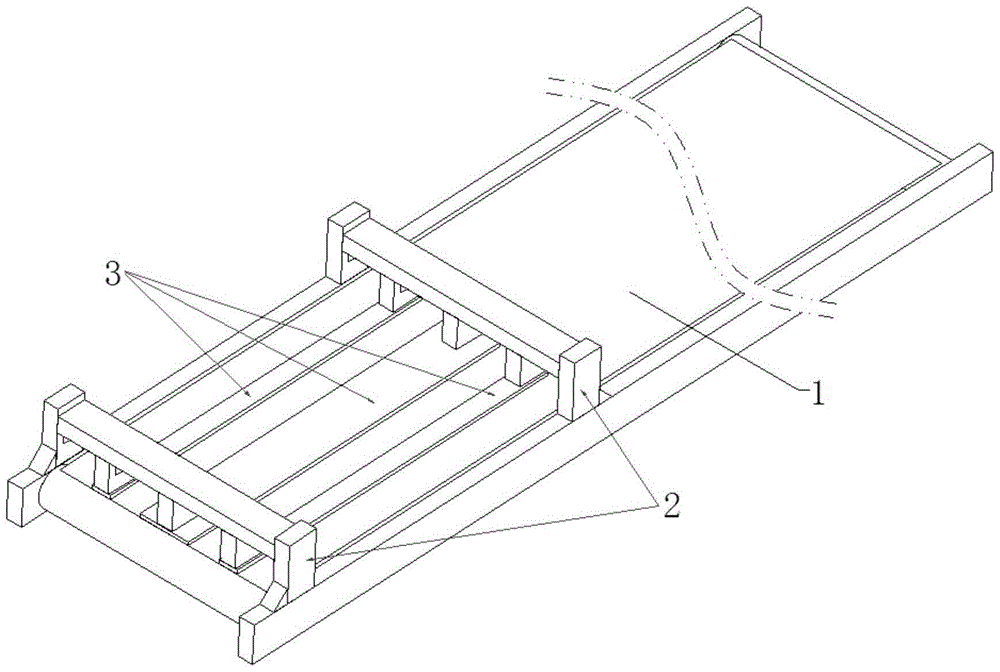

[0025] Such as Figure 1-2 As shown, an automatic arrangement device for circuit breaker housings includes a conveyor belt 1, a platform 14 and an automatic arrangement device. The automatic arrangement device is arranged on the platform 14. The automatic arrangement device includes a Connecting plate 4, the end of the connecting plate 4 away from the conveyor belt 1 is provided with a blocking cylinder 5, the blocking cylinder 5 is perpendicular to the conveying direction of the article on the connecting plate 4, and the blocking cylinder 5 is located on the connecting plate 4 One end of the product is provided with a product overturning structure, and the side where the product is ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com