Automatic production and arrangement equipment of N nails

A technology of automatic production and equipment, applied in the direction of mechanical equipment, metal processing equipment, nails, etc., can solve the problems of a large amount of labor and slow production rate of N nails, and achieve the effect of reducing the input of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

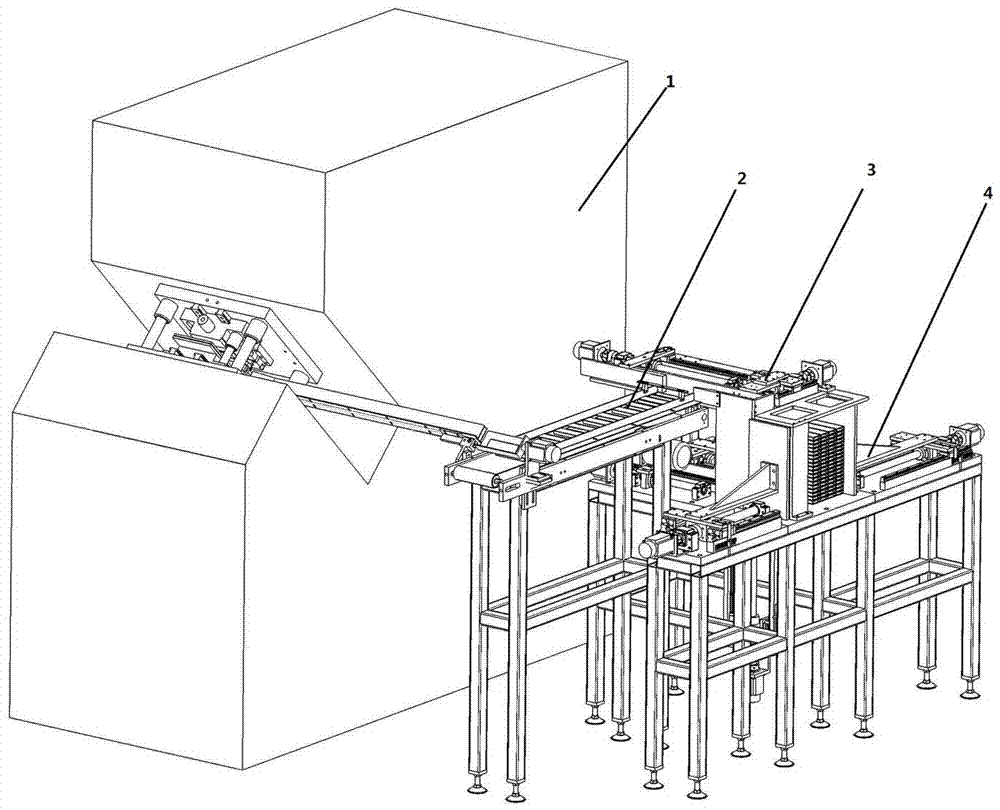

[0025] An automatic production and arrangement equipment for N nails, comprising a punch 1, a feeding device 2, an N nail fastening device 3, and an arrangement and stacking device 4, the punch 1 is connected to a feeding device 2, and the feeding device 2 is connected to the N nails Buckling device 4 , the arrangement and stacking device 4 is installed under the N nail buckle device 3 .

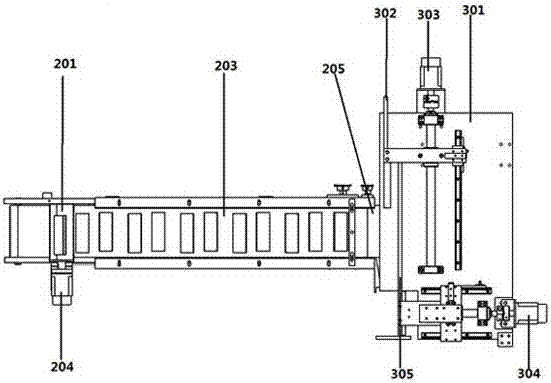

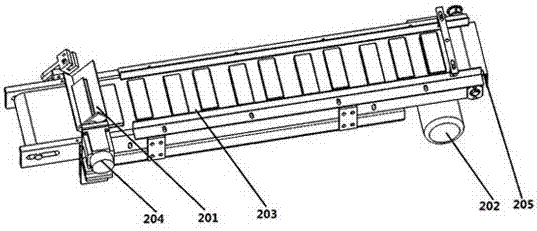

[0026] The feeding device 2 includes a turning mechanism, a transmission belt 203, a motor one 202, and a connecting plate 205. The turning mechanism includes a motor two 204 installed at the front end of the conveyor belt 203, and a turning plate 201 connected to the motor two 204. The motor A 202 is installed under the conveyor belt 203 , and the connecting plate 205 is installed at the tail of the transmission belt 203 and is connected to the N-pin fastening device 3 . The rotation direction of the turning plate 201 is changed by the second motor 204 , so that the N nails are conveyed alt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com