Mechanical automatic-turnover locating device

A positioning device and self-turning technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of complicated pipelines or wires, easy entanglement during movement, troublesome ventilation or power supply, etc., and achieve simple and beautiful appearance, mechanical Simple structure, reducing the effect of pipelines and lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

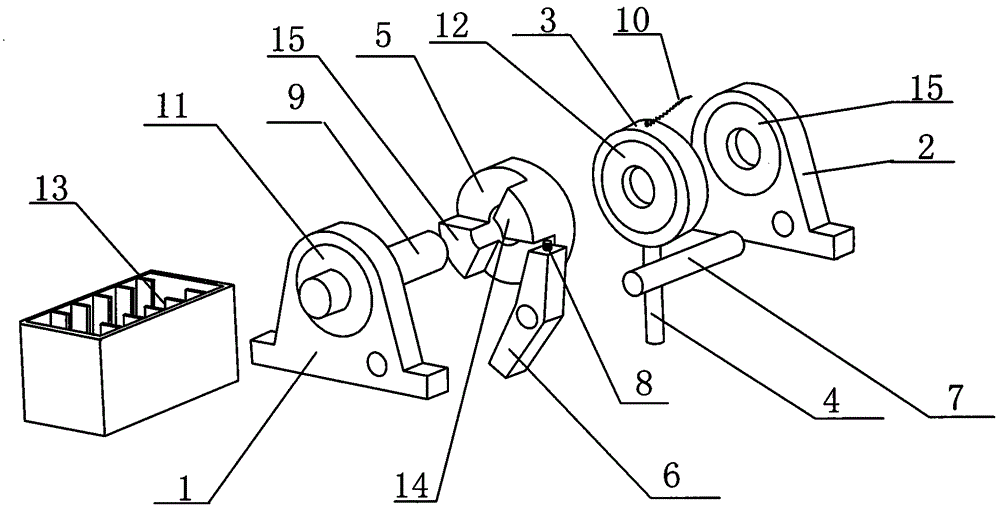

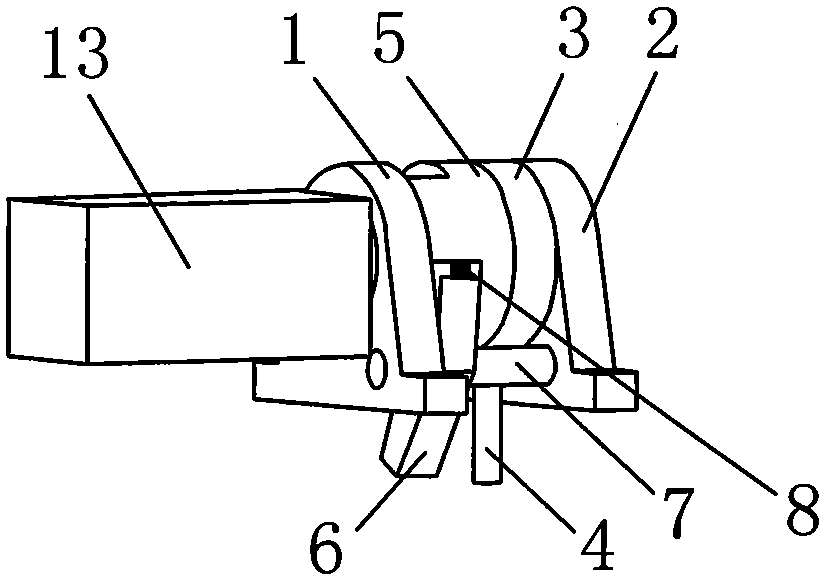

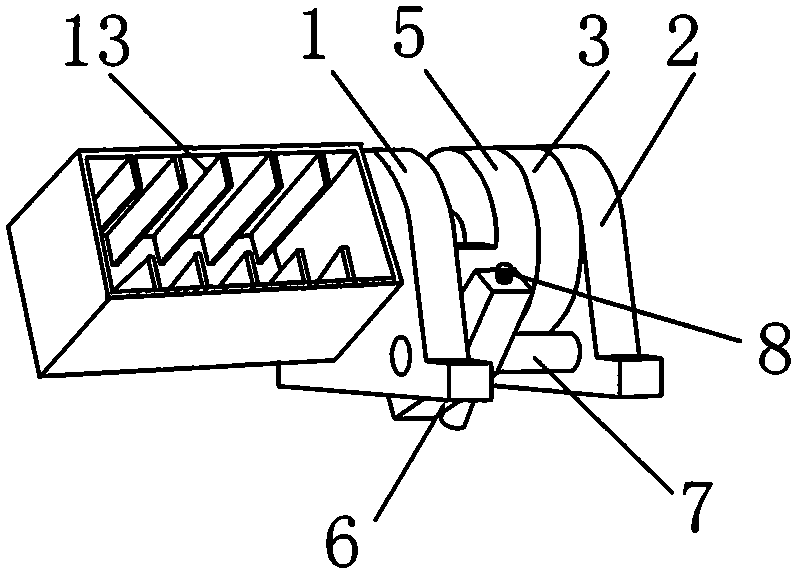

[0017] The mechanical self-turning positioning device of the present invention such as figure 1 As shown, base one-way bearings 11 and 15 are respectively embedded on the front base 1 and the rear base 2, and a rotating power ring 3 and a positioning rotating block 5 are arranged between the front base 1 and the rear base 2. The power ring 3 is embedded with a one-way bearing 12, the bottom of the rotating power ring 3 has a power ring pin 4, and there are two protrusions 14 on the positioning rotating block 5, and the main shaft 9 passes through the rear base 2, the rotating power ring 3, The positioning rotating block 5, the front base 1 and the assembly station 13 are fixedly assembled, the positioning rotating block 5 is fixedly assembled with the main shaft 9, and the base one-way bearings 11 and 15 embedded in the front base 1 and the rear base 2 are the same One-way rotation in one direction, the one-way bearing 12 on the rotating power ring 3 and the one-way bearings 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com