Oxygenation method of a liquid constant value oxygenation system

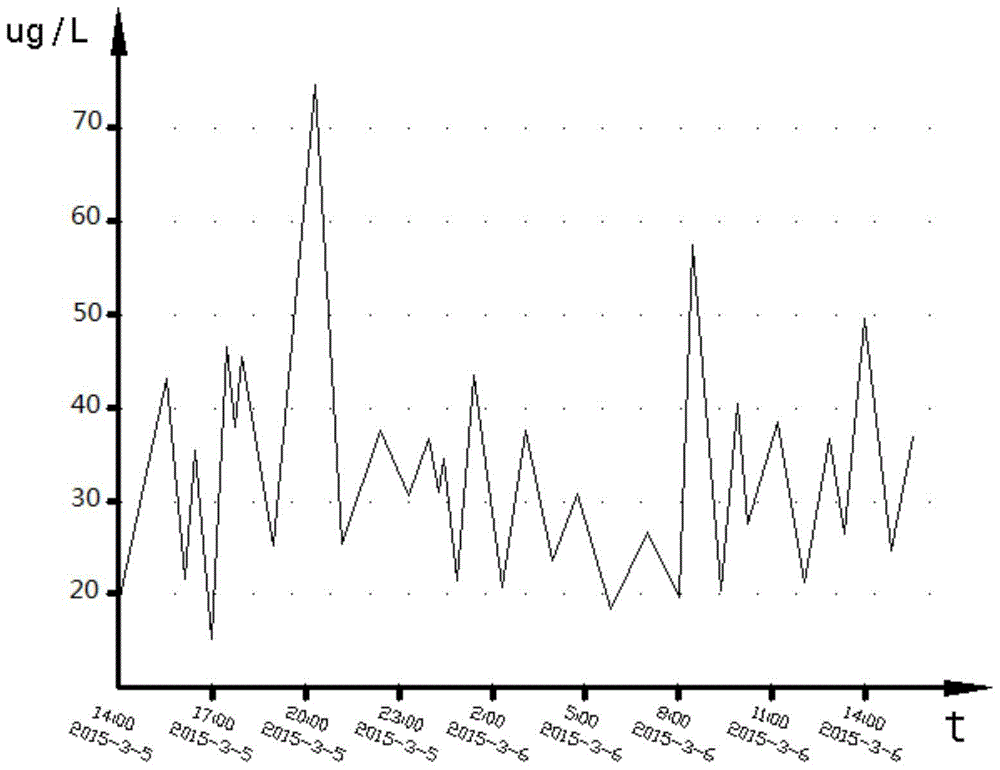

A constant value, liquid technology, applied in the field of liquid constant value oxygenation system, can solve the problems of poor operation effect, economic loss, large fluctuation range of oxygen amount, etc., to enhance integrity and fixity, and avoid control technical problems , to ensure the effect of chemical kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The working principle of the present invention will be described in more detail below in conjunction with the accompanying drawings.

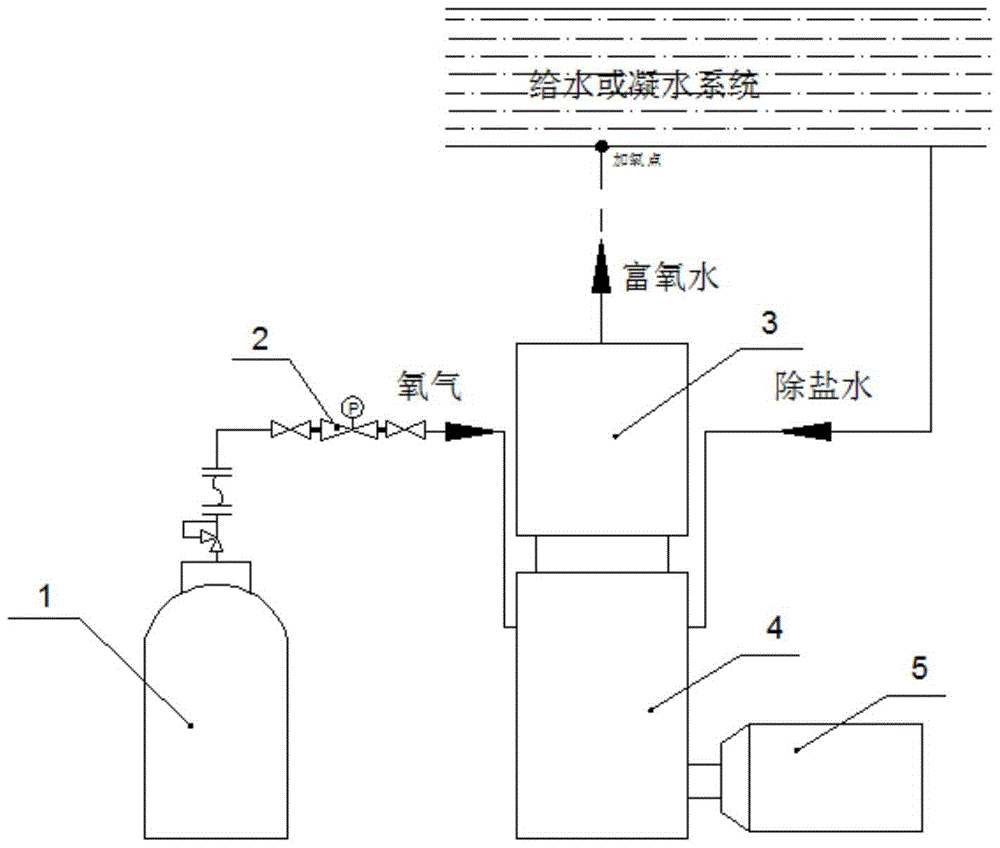

[0020] Such as figure 2 As shown, a liquid constant value oxygen addition system includes an oxygen bottle 1, and also includes an oxygen-enriched water generator 4 communicated with the oxygen bottle 1, and a reducing device is arranged on the pipeline connecting the oxygen bottle 1 and the oxygen-enriched water generator 4. Compressor 2, the oxygen-enriched water generator 4 is connected with desalinated water, and the oxygen-enriched water generator 4 is connected with a power box 5 that provides power for the mixing of oxygen and desalinated water, and the oxygen-enriched water generator 4 The pipeline is in communication with the oxygenation point of the water supply or condensate system, and the oxygenation pipeline is provided with a delivery device 3 that transports the oxygen-enriched water generated by the oxygen-enriched wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com