Piston of rotary compressor and rotary compressor with same and multistage compressor with same

A rotary compressor and piston technology, applied in the field of compressors, can solve the problems of complex design process and assembly process, increase the eccentric inertial force of the crankshaft, and influence the reliability of the compressor, and achieve weight reduction, reduction of the rotating eccentric inertial force, Vibration and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

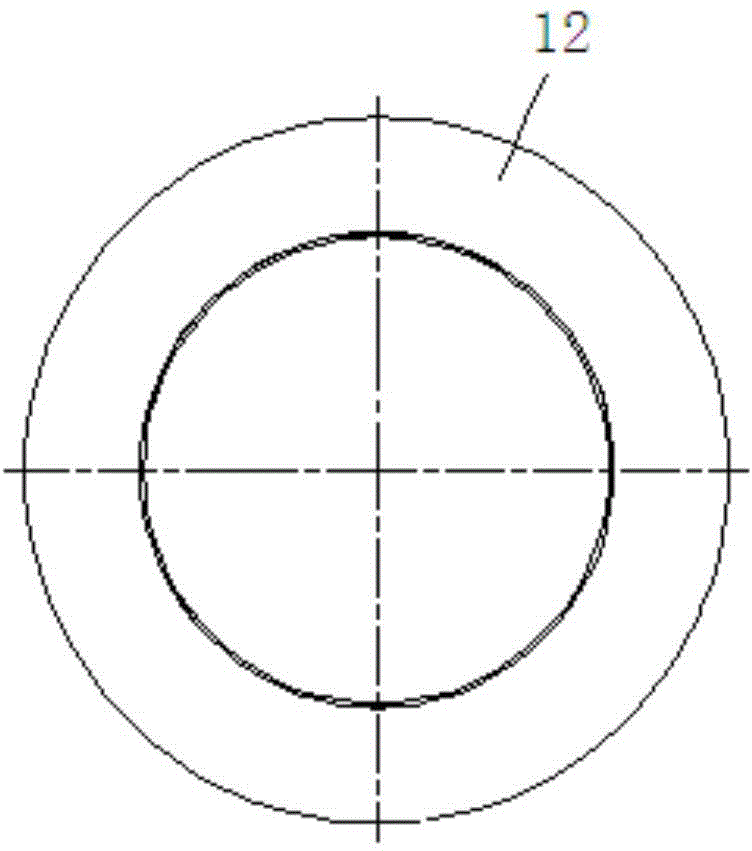

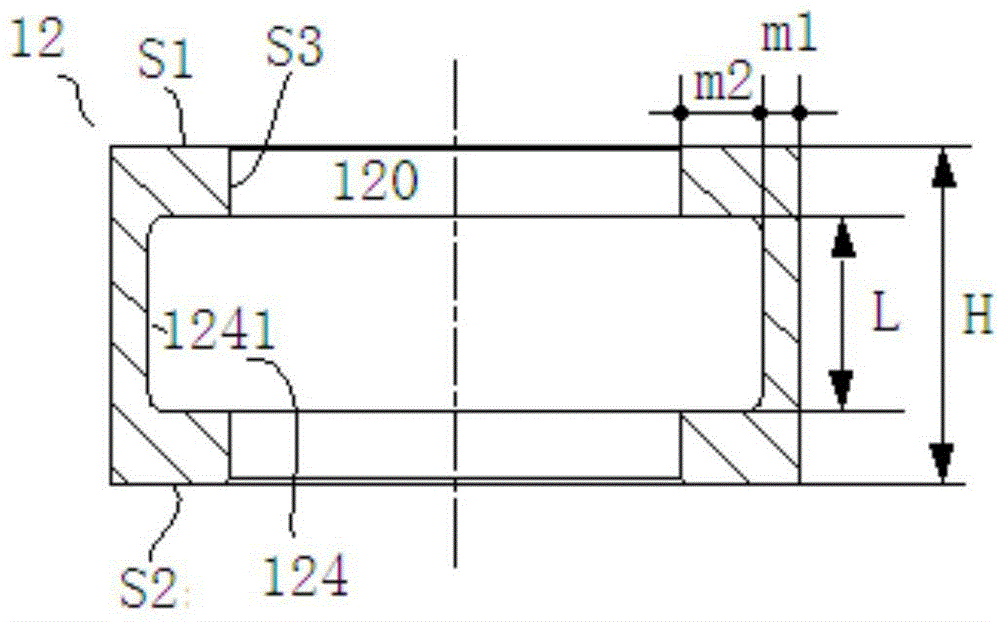

[0050] In this example, if image 3 As shown, the groove 124 in the piston 12 includes a sub-groove 1241 .

[0051] Specifically, the sub-groove 1241 is arranged around the central hole 120, and the sub-groove 1241 is annular, that is, the inner wall surface S3 of the central hole 120 is provided with one sub-groove 1241 along the entire circumference, which reduces the weight of the piston 12 to the greatest extent. , the purpose of reducing the inertial force of the eccentric portion 62 is achieved.

[0052] Wherein, when the axial height L of the groove 124 is too large, it is impossible to ensure that the inner wall surface S3 of the central hole of the piston 12 is fully in contact with the outer peripheral wall of the eccentric part of the crankshaft 6, and when the axial width L of the groove 124 is too small, The effect of the groove 124 on the eccentric balance of the eccentric component is not obvious, therefore, the axial height L of the groove 124 needs to be rest...

Embodiment 2

[0056] In this example, if Figure 4 As shown, the structure of the piston 12 is substantially the same as the structure of the piston 12 in Embodiment 1, and will not be repeated here.

[0057] The difference is that, in the second embodiment, the groove 124 in the piston 12 includes a plurality of sub-grooves 1241 , that is, the number of sub-grooves 1241 is 2 or more.

[0058] Specifically, the groove 124 includes a plurality of annular sub-grooves 1241 arranged at intervals along the axial direction of the central hole 120 . In this way, the part between two adjacent sub-grooves 1241 constitutes the reinforcing rib 1242 , thereby increasing the structural strength of the piston 12 on the premise of reducing the weight of the piston 12 and ensuring that the piston 12 is not easily deformed.

[0059] When there are multiple sub-grooves 1241 , the axial height L of the groove 124 is the sum of the axial heights of the plurality of sub-grooves 1241 . Wherein, the axial heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com