Anisotropic rock damage degree test device and test method thereof

A technology of damage degree and anisotropy, which is applied in the field of anisotropic rock damage degree test device, can solve the problem that the test results stay in a qualitative angle, cannot accurately judge the exact damage degree of damage to rock, and aggravate rock anisotropy characteristics, etc. problem, achieve the effect of saving experimental equipment investment, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

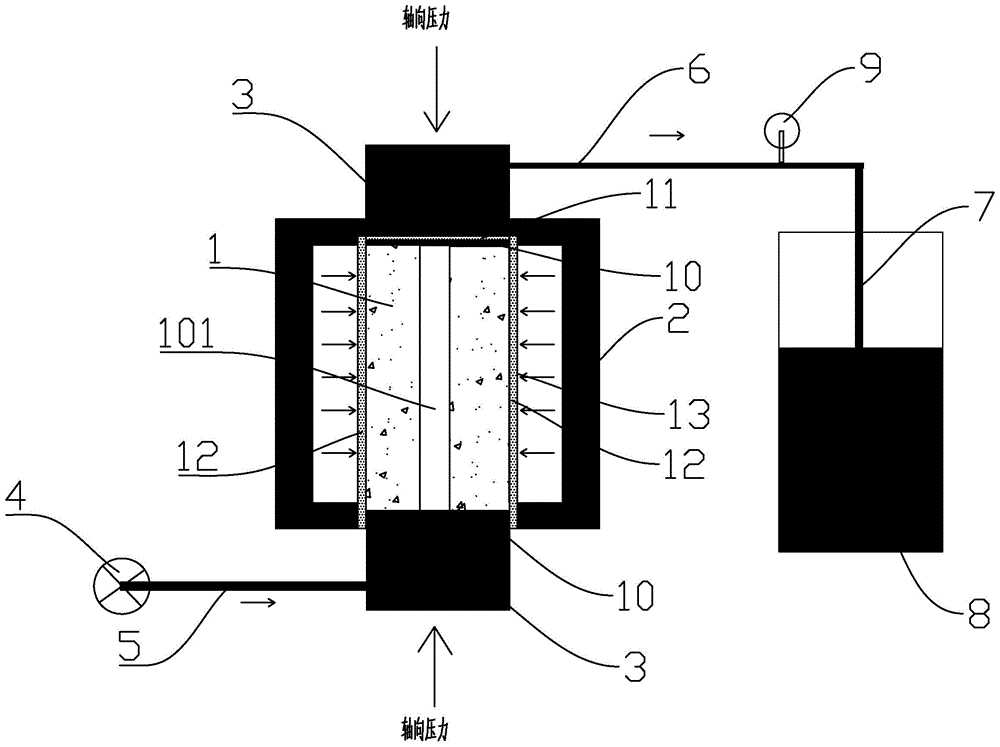

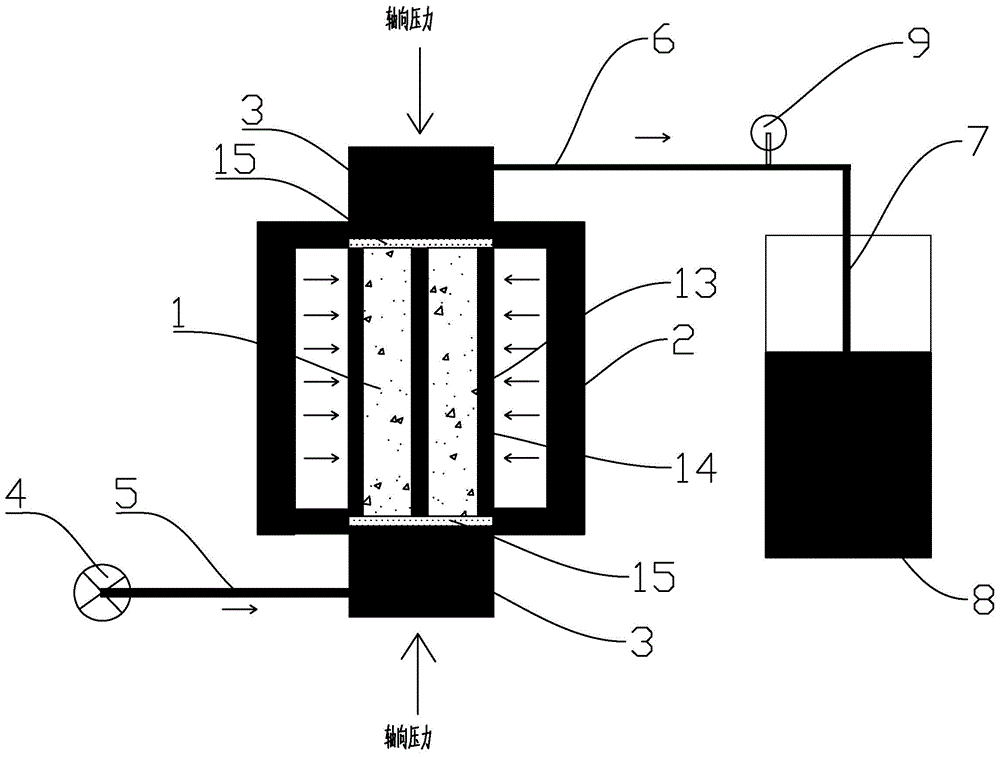

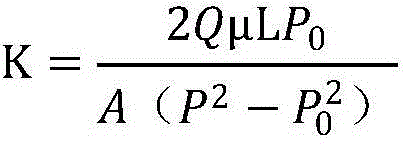

[0032] This embodiment is an anisotropic rock damage degree testing device, which includes an axial pressurization device 3, a circumferential pressurization device 2, a pressurizing plate, an airtight sleeve 13, a pressurizing pump 4, air inlet and outlet pipes 5, 6. The water storage container 8, the pressure gauge 9 and the measuring tube 7, which can be used to test the circumferential gas permeability coefficient and the axial gas permeability coefficient of the rock sample 1 (with the middle borehole 101) respectively.

[0033] figure 1 It is a test device for testing the circumferential gas permeability coefficient of the rock sample 1. The rock sample 1 is placed in the circumferential pressurization device 2, and the circumferential pressurization device applies a circumferential pressure to the rock sample. The upper and lower ends of the rock sample 1 are provided with There is an axial pressurizing device 3, which applies axial pressure to the rock sample. In this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com