Current sensor framework applicable to square face-to-face plugging magnetic cores

A current sensor and skeleton technology, applied in the field of compensated Hall current sensors, can solve the problems of inability to wind the coil and affect the application, and achieve the effect of reducing the risk of short circuit, improving reliability, and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

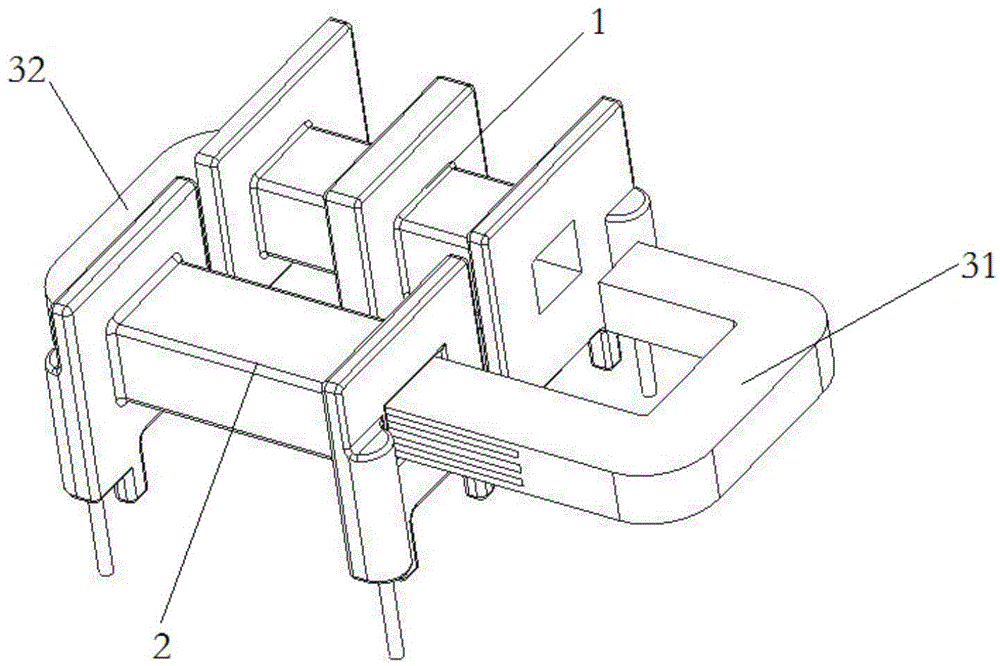

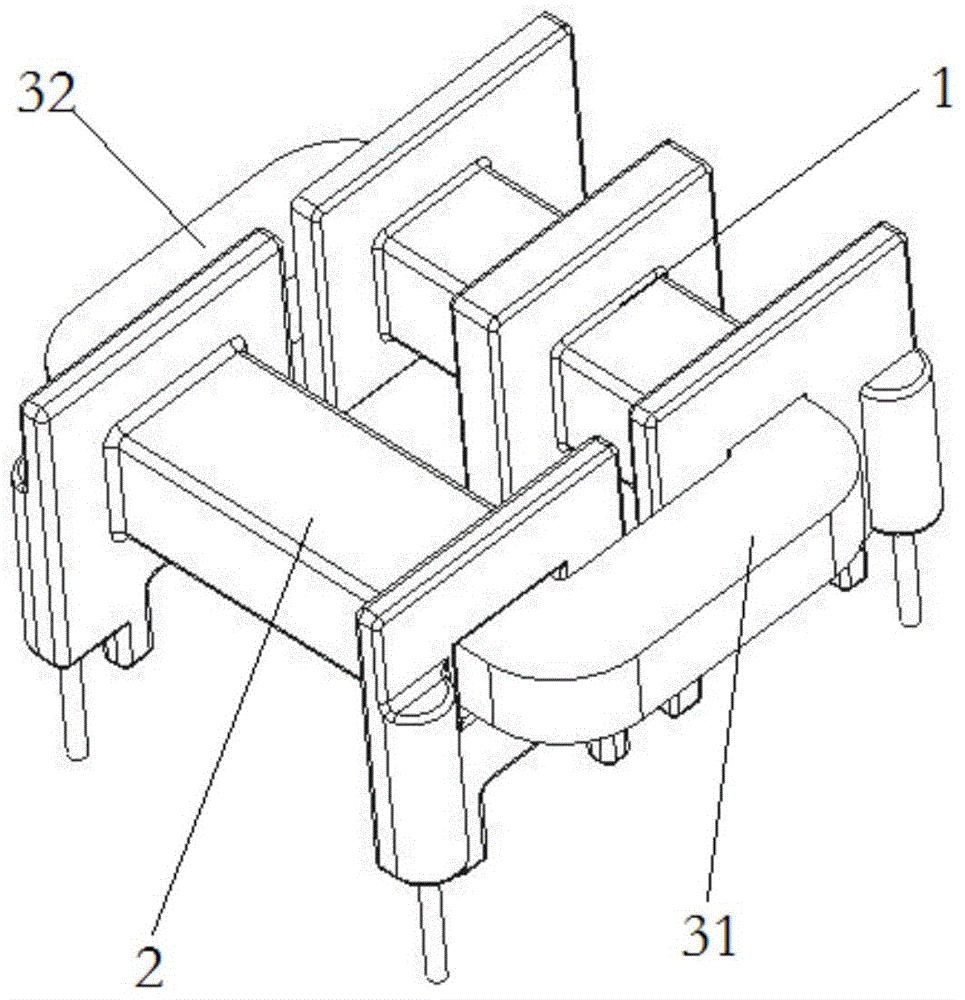

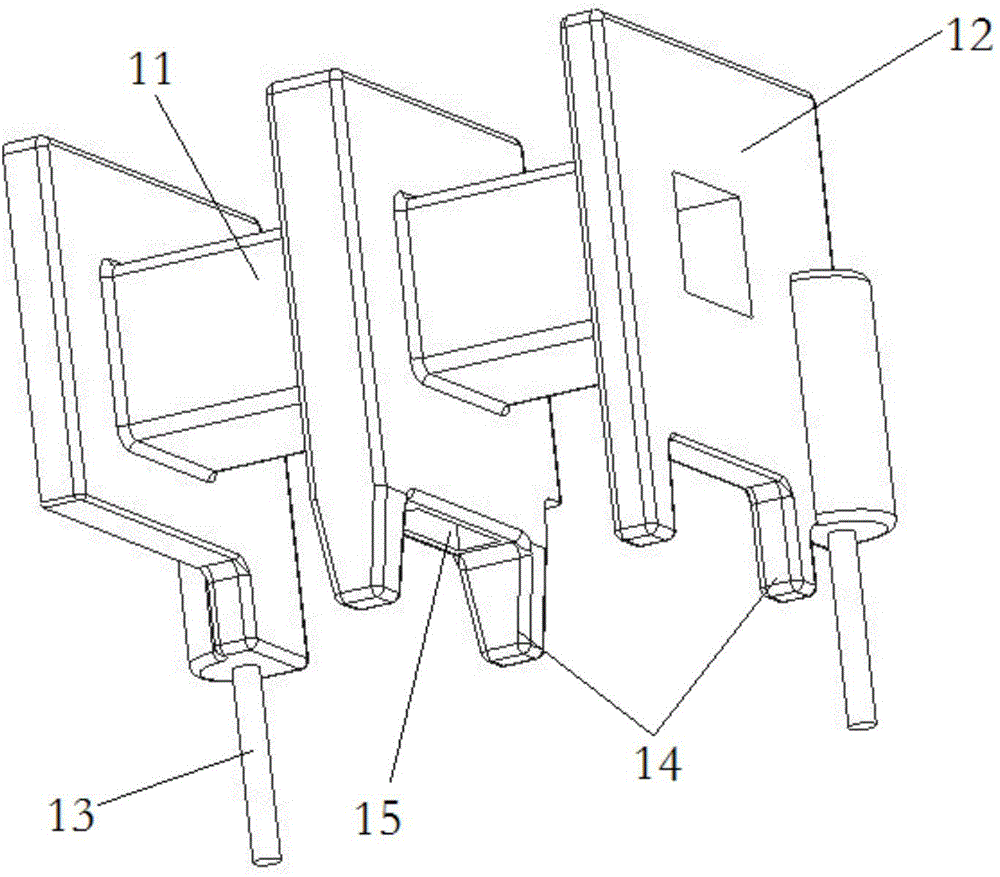

[0025] The novel framework of the present invention also includes a first framework 1 and a second framework 2; the structure of the first framework 1 is similar to the existing framework shown in Figure 1, including a straight square frame 11 for accommodating the magnetic core of the current sensor The butt joint part 34 of the square frame 11 is provided with a circle of flanges 12 at both ends and the middle of the outer circumference of the square frame 11, and a compensation coil is wound on the square frame 11 between two adjacent flanges 12. A square groove 15 is left at the bottom of the middle flange 12 for fixing the Hall element. The difference is that in the present invention, a wire slot 26 is processed at the bottom of the middle flange 12 to protect the passing enameled wire from damage. There are support legs 14 on both sides, which is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com