Replacement Lens Barrel

A lens barrel and lens technology, applied to instruments, installations, camera bodies, etc., can solve the problems of complicated manufacturing processes, rising manufacturing costs, shortening lens barrels, etc., to achieve good operability and improve portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

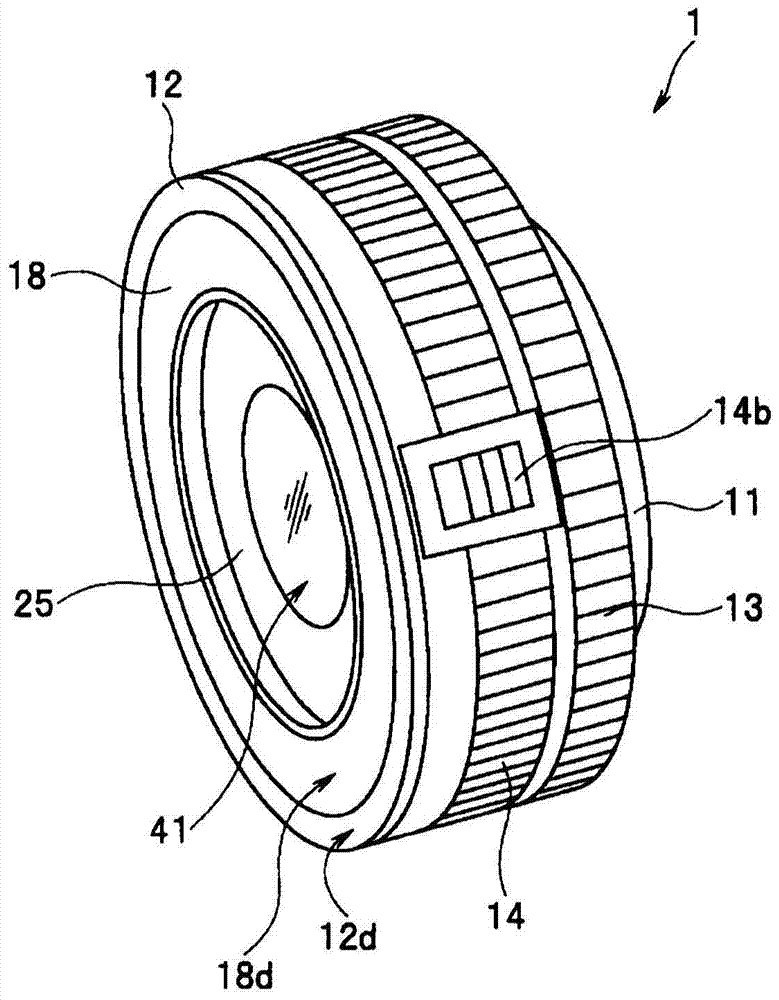

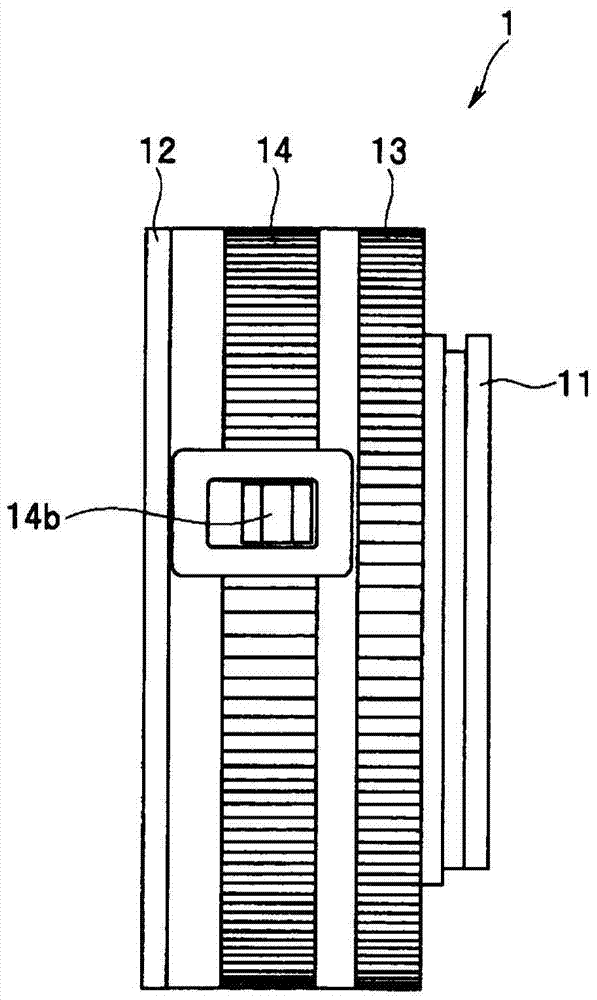

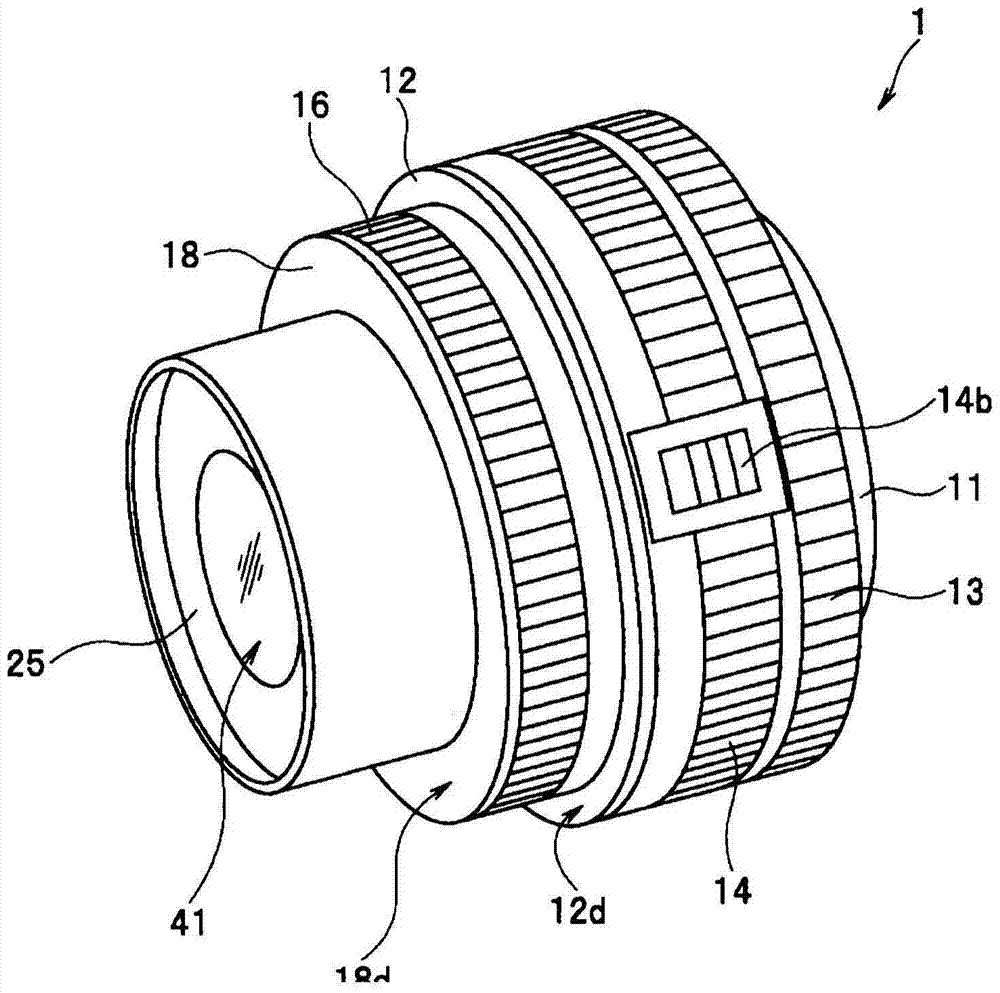

[0043] Figure 1 to Figure 10 It is a figure which shows the zoom lens barrel of 1st Embodiment of this invention. in, figure 1 It is a perspective view of the external appearance of the zoom lens barrel of the present embodiment in a contracted state. figure 2 yes figure 1 A side view of the appearance of the state of the zoom lens barrel. image 3 It is a perspective view of the appearance of the zoom lens barrel according to the present embodiment when it is in use. Figure 4 yes image 3 A side view of the appearance of the state of the zoom lens barrel. Figure 5 ~ Figure 7 It is an exploded perspective view of the zoom lens barrel of this embodiment. in, Figure 5 The structure of the front half of the zoom lens barrel of this embodiment is shown. Image 6 The structure of the rear half of the zoom lens barrel of this embodiment is shown. Figure 7 It is an exploded perspective view of main parts of the focus drive unit of the zoom lens barrel of the present em...

no. 2 Embodiment approach

[0111] The second embodiment of the present invention is exemplified when it is applied to an interchangeable zoom lens barrel used in an imaging device such as a digital camera (hereinafter simply referred to as a camera) configured as follows: The optical image is photoelectrically converted, the resulting image signal is converted into digital image data representing a still image or a moving image, and the digital data generated in this way is recorded in a recording medium, and the digital image data recorded in the recording medium can be A still image or a moving image is reproduced and displayed on the display device.

[0112]Furthermore, the interchangeable zoom lens barrel of the present embodiment is a zoom lens barrel configured to be detachable from a camera as an optical device. Furthermore, the interchangeable zoom lens barrel of the present embodiment is a shrinkable lens barrel having a contraction mechanism that shortens the state during non-shooting compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com