Ground adaptive device, method and application of self-propelled cabbage harvester

An adaptive, self-propelled technology, applied in the field of agricultural machinery, can solve the problems of high contact resistance between the anti-sinking pallet and the ground, and increased mechanical power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and example.

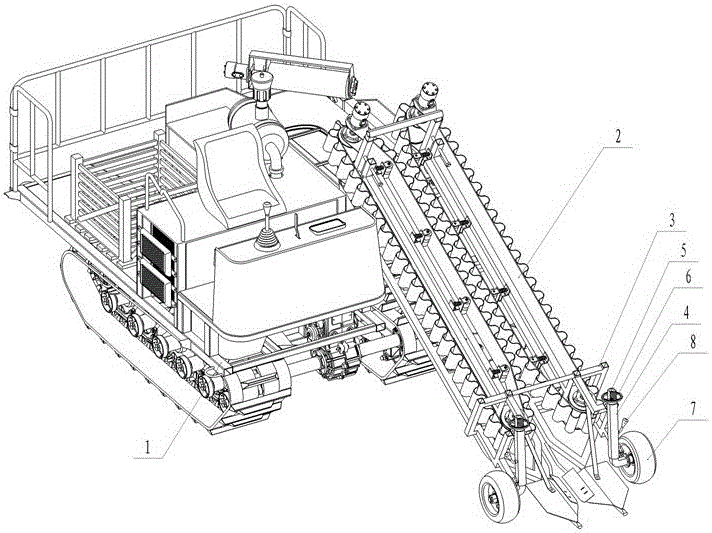

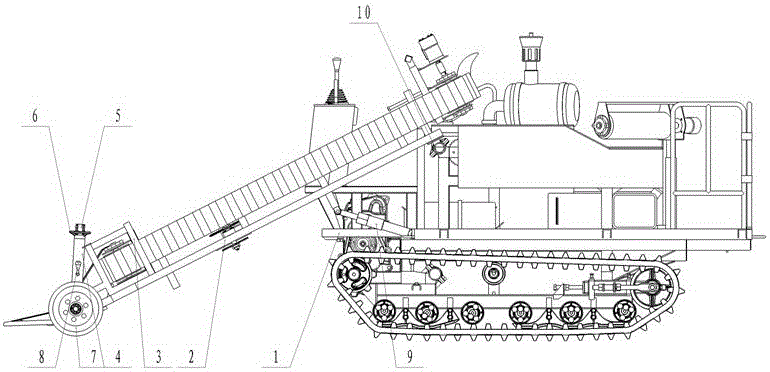

[0016] Such as figure 1 , figure 2 As shown, a ground adaptive device of a self-propelled cabbage harvester includes a power chassis 1, a harvesting platform assembly 2, and a ground self-adaptive device assembly. The harvesting platform assembly 2 is assembled on the power chassis 1, and the power chassis 1 It is crawler type and supplies the power of the whole machine:

[0017] The ground self-adaptive device assembly is located at the front end of the harvesting platform assembly 2, which is a left-right symmetrical structure and adopts a double-wheel form; the right ground self-adaptive device assembly includes a limit ground wheel frame 3, a threaded adjustment rod sleeve 4, and a threaded adjustment rod 5 , adjusting hand wheel 6, limit ground wheel 7, self-locking handle 8; limit ground wheel frame 3 is as the frame that ground self-adaptive device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com