Method and device for hot rolling forming of super-strength steel

A technology of ultra-high-strength steel and roll forming, which is applied in the field of hot rolling, can solve problems such as the strength of difficult-to-form parts and difficulty in meeting the use requirements, and achieve the effects of increased production efficiency, good heating efficiency, and cost avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

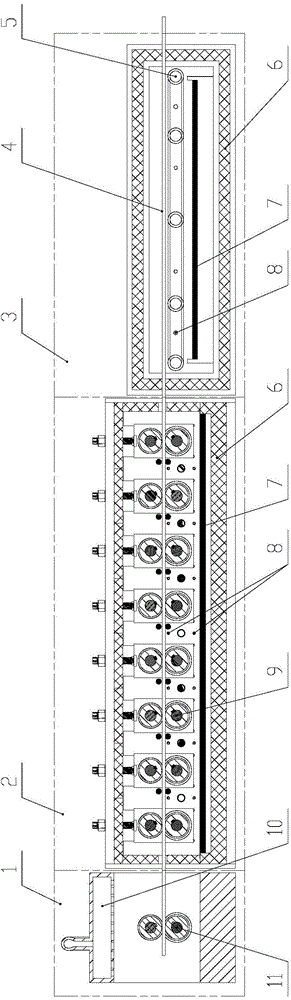

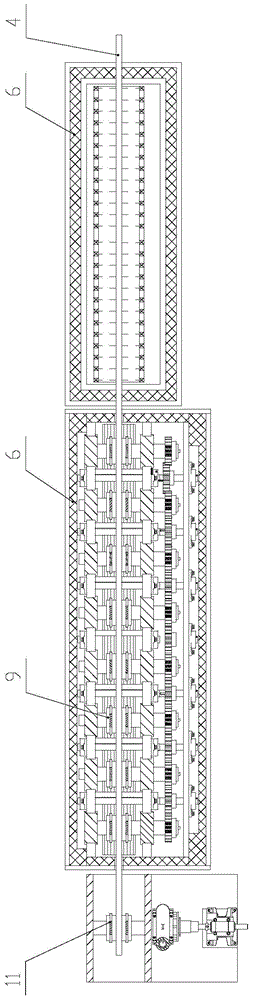

[0029] Specific embodiments of the present invention, such as figure 1 , 2 Shown, a kind of ultra-high-strength steel hot roll forming method, comprises the following steps:

[0030] ①. Send the sheet 4 at normal temperature to the feeding port of the heating conveyor 3;

[0031] ② After the sheet 4 enters the heating conveyor 3, it is continuously heated by the high-temperature heater 7, and the temperature controller 8 is used to control the temperature of the entire heating conveyor 3, so that the sheet 4 is completely austenitized in the heating conveyor 3 , the temperature is controlled at 800-1200°C, and the holding time is 3-10 minutes;

[0032] ③. After the sheet material 4 comes out from the discharge port of the heating conveyor 3, it is directly conveyed into the roll forming machine 2, and the high temperature heater 7 and the temperature controller 8 provided in the roll forming machine 2 ensure that the sheet material 4 is in the whole Keep the same temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com