Metal powder for powder metallurgy, compound, granulated powder, sintered body, and method for producing sintered body

A technology of powder metallurgy and metal powder, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of inevitable high cost and increased working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

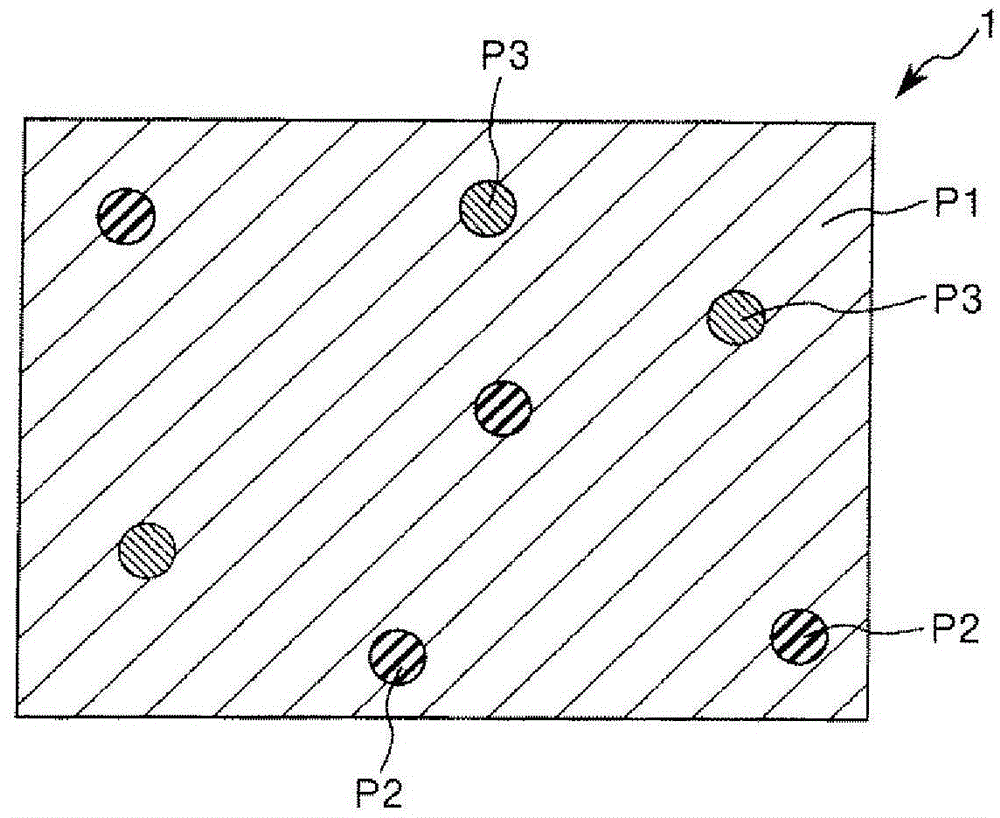

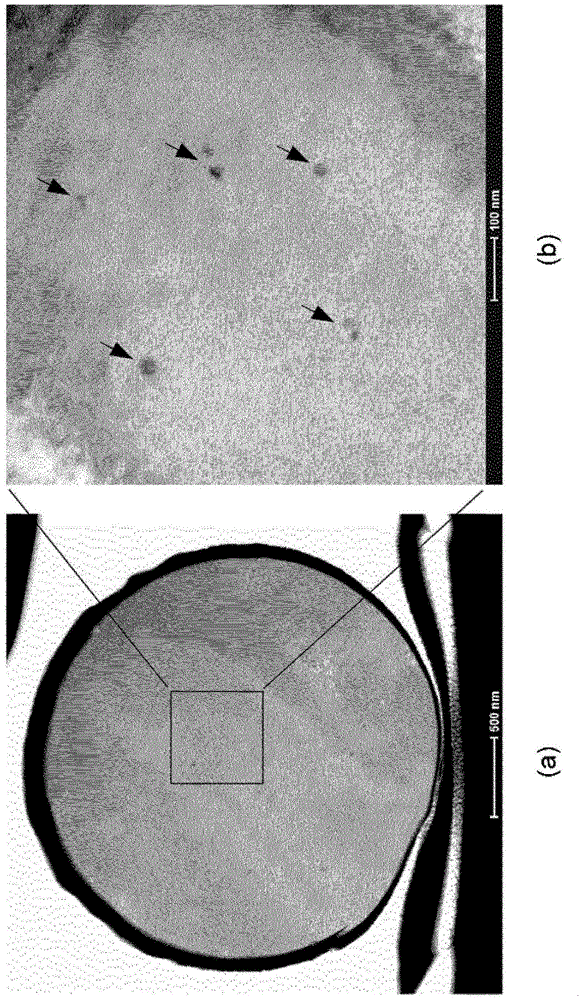

[0052] Hereinafter, the metal powder for powder metallurgy, the composite, the granulated powder, the sintered body, and the method for producing the sintered body of the present invention will be described in detail based on preferred embodiments shown in the drawings.

[0053] [Metal powder for powder metallurgy]

[0054] First, an embodiment of the metal powder for powder metallurgy of the present invention will be described.

[0055] In powder metallurgy, a sintered body of a desired shape can be obtained by molding a composition including a metal powder for powder metallurgy and a binder into a desired shape, followed by degreasing and firing. According to this powder metallurgy technique, compared with other metallurgy techniques, there is an advantage that a sintered compact having a complex and fine shape can be produced in a near-net shape (a shape close to the final shape).

[0056] Conventionally, as a metal powder for powder metallurgy used in powder metallurgy, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap