A processing method of cylindrical roller bearing cage

A technology of cylindrical roller bearings and processing methods, which is applied in the field of machinery, can solve problems such as the difference in positional relationship between riveted joints and cylindrical pockets on the cage seat, and reduce the quality of the cage, so as to improve the processing quality, improve the position degree, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

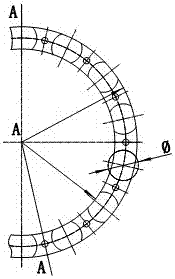

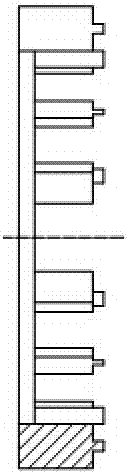

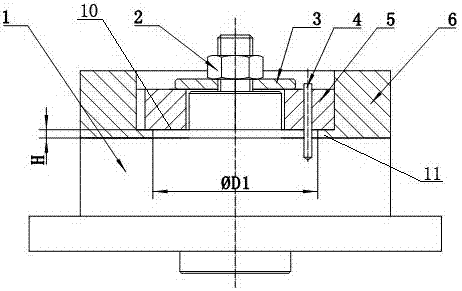

[0020] As shown in the figure, a processing method of a cylindrical roller bearing cage, first roughing the end face, outer circumference and inner circumference of the cage seat 6 according to the conventional method, and reserve an annular step 11 at the inner diameter of one end , the inner diameter of the step 11 is slidingly matched with the outer diameter of the ring-cut clamping table 10 set on the mandrel 1; the cage cover 8 is also processed with the mandrel 1 and its corresponding accessories, but the inner diameter does not need to leave a step; install the mandrel 1 On the base of the machine tool, adjust its radial runout to an appropriate range, and then fix the mandrel 1. Install the cage seat 6 on the mandrel 1, press the pressure block 5 against the step 11 of the cage seat 6, fix the pressure block 5 and the mandrel 1 with the positioning pin 4, prevent the relative rotation of the two, and then pass the nut 2 through the washer 3 Press the cage seat 6 and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com