Pneumatic tire

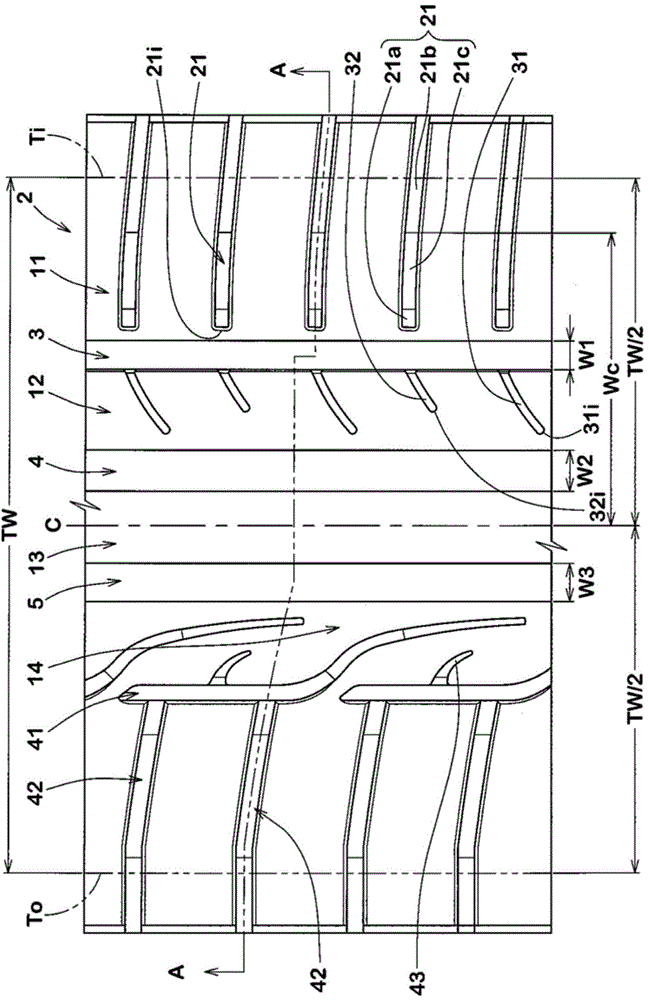

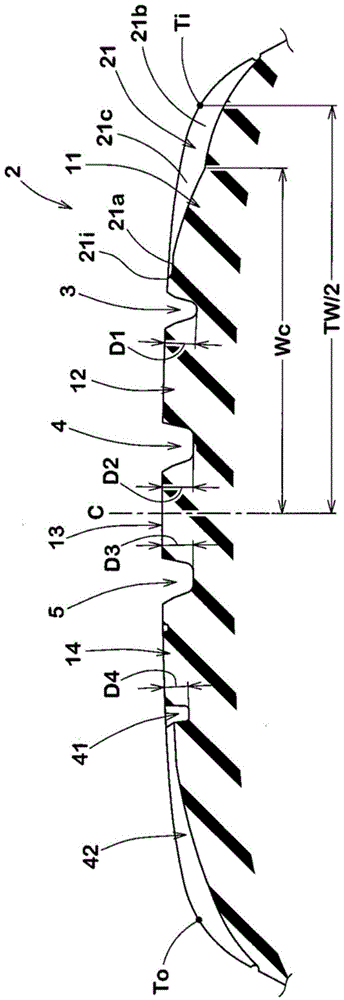

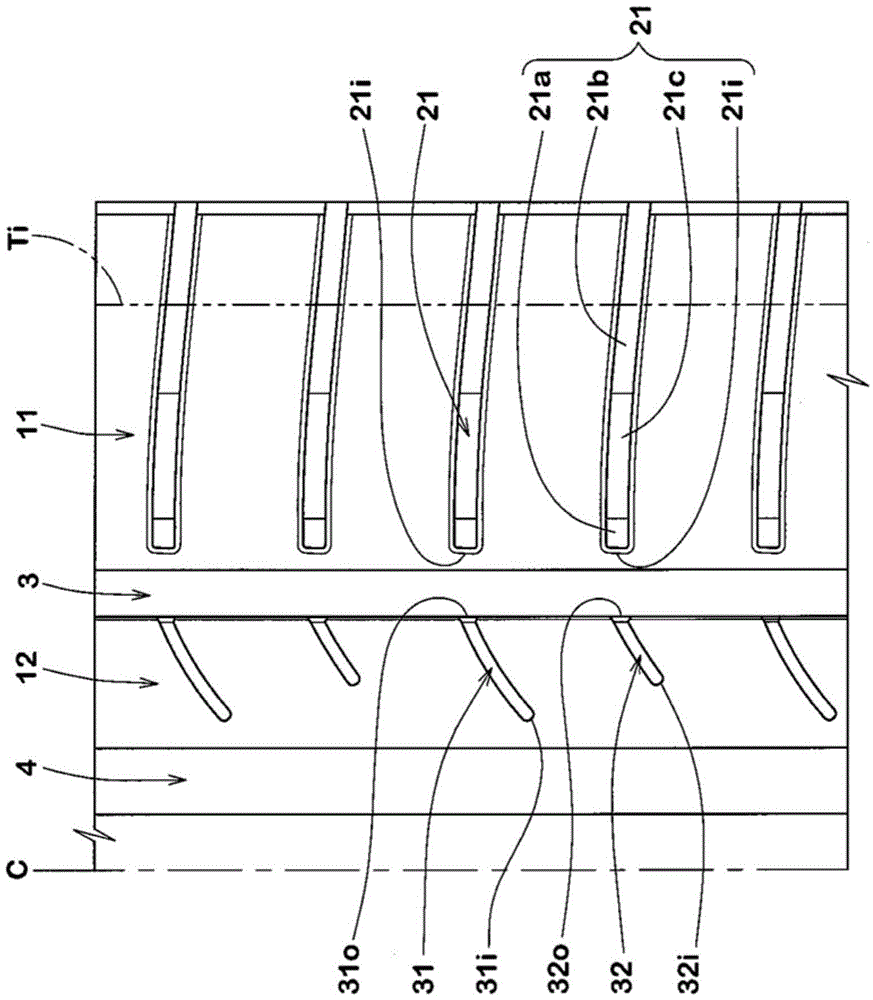

一种充气轮胎、轮胎的技术,应用在充气轮胎、轮胎零部件、轮胎胎面/胎面花纹等方向,能够解决胎肩横纹沟排水性能降低、干燥路面转弯性能变差、胎面部刚性降低等问题,达到提高排水性能、提高转弯性能、提高排水性能与外观性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Prototypes based on the specifications in Table 1 have figure 1 The tread pattern size is 245 / 40R18 pneumatic tires, and the turning performance, drainage performance and appearance performance in the middle of wear are tested. The test method is as follows.

[0055]

[0056] For a test tire mounted on a rim of 18×8.5J, the maximum cornering force was measured using a flat belt testing machine under the conditions of an internal pressure of 230kPa and a load of 6.86kN. The result is shown by the index which set Example 1 to 100. A larger value indicates better cornering performance.

[0057]

[0058] A vehicle mounted with the above-mentioned pneumatic tire was run on a wet road surface having a road surface μ of 0.3 and a water depth of 1.4 mm, and the ease of turning was evaluated by the driver's senses. The results are shown by setting Example 1 as a score of 100, and the larger the numerical value, the better the drainage performance.

[0059]

[0060] The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap