Cross beam transport material rack

A material rack and beam technology, which is applied in the field of beam transport material racks, can solve problems such as the tight space in the production workshop, and achieve the effects of reducing logistics costs, saving space, and saving production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

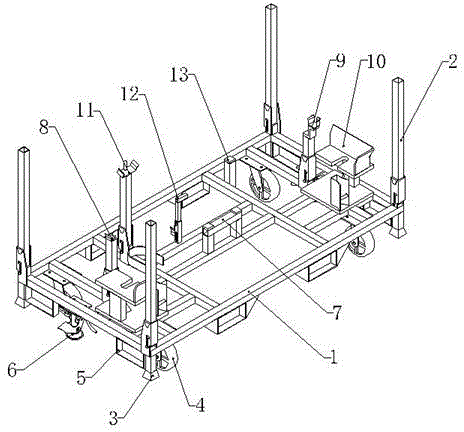

[0027] Utilize the first positioning mechanism to position and store the product. The positioning block I11 and the positioning block II12 of the second positioning mechanism are also connected with the bottom frame 1 by the sliding groove structure as the movable column 2. After the positioning block I11 and the positioning block II12 are respectively pulled upward, the protrusions of the positioning block I11 and the positioning block II12 The block 19 exits from the V-shaped groove 16, and the positioning block I11 and the positioning block II12 are placed sideways on the open side of the support 14 on the chassis 1, so that the positioning block I11 and the positioning block II12 do not affect the first positioning mechanism on the product. Positioning storage, positioning block III13 does not affect product storage due to its short length.

[0028] Use the positioning plate I7, the positioning plate II8, the positioning plate III9 and the positioning plate IV10 of the fir...

Embodiment 2

[0030] Utilize the second positioning mechanism to locate and store additional products. The positioning plate II8 and the positioning plate III9 of the first positioning mechanism are also connected with the bottom frame 1 by the sliding groove structure as the movable column 2. After the positioning plate II8 and the positioning plate III9 are respectively pulled upward, the protrusions of the positioning plate II8 and the positioning plate III9 will Block 19 exits from the V-shaped groove 16, and the positioning plate II8 and positioning plate III9 are placed sideways on the open side of the support 14 on the chassis 1, so that positioning plate II8 and positioning plate III9 do not affect the first positioning mechanism on the product. Positioning storage, positioning plate I7 and positioning plate IV10 do not affect the storage of products due to their short length.

[0031] Utilize the positioning block I11, the positioning block II12 and the positioning block III13 of...

Embodiment 3

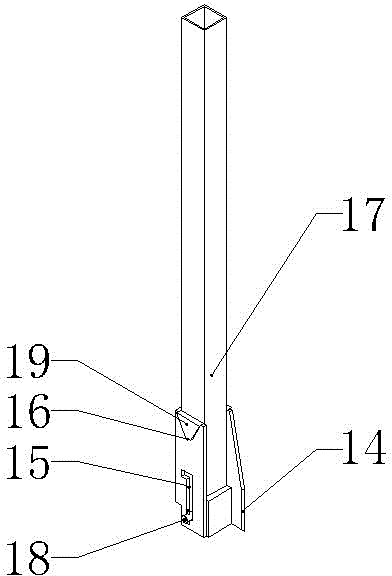

[0033] The upright and flat laying of movable column 2.

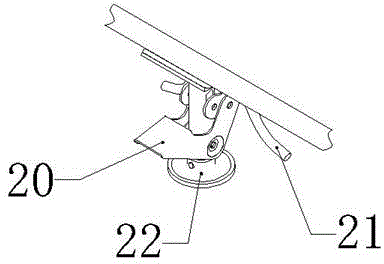

[0034] When the transport material rack needs to store products, the movable column 2 is in an upright state, that is, the protrusion 19 of the movable column 2 is put into the V-shaped groove 16, and the V-shaped groove 16 blocks the protrusion 19, thereby fixing the Upright bar 17, upright bar 17 is upright state, and promptly movable column 2 is upright state. At this moment, the bottom of the support foot 3 can cooperate with the movable column 2, and the bottom of the support foot 3 of one transport material rack is stacked on the top of the vertical bar 17 of another transport material rack. put, effectively saving space.

[0035] When the transport material rack does not need to store products, lift up the vertical rod 17, the block 18 slides upward in the chute 15, and the protrusion 19 moves upward to break away from the V-shaped groove 16. At this time, the vertical rod 17 can be placed on the open side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com