Automatic striping and taking device and method

A reclaiming device and stripping technology, which is applied in the direction of transportation and packaging, packaging, conveyor objects, etc., can solve the problem that the stripping and retrieving processes cannot be well integrated, the work efficiency is not high, and the material and material belt Unsatisfactory peeling effect and other problems, to achieve ideal peeling effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

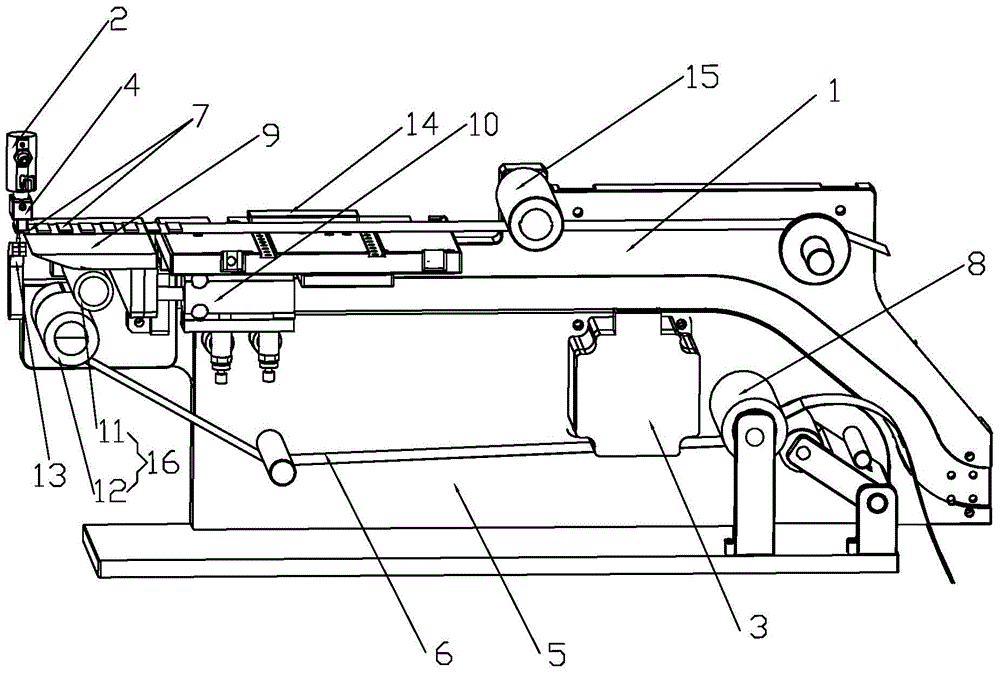

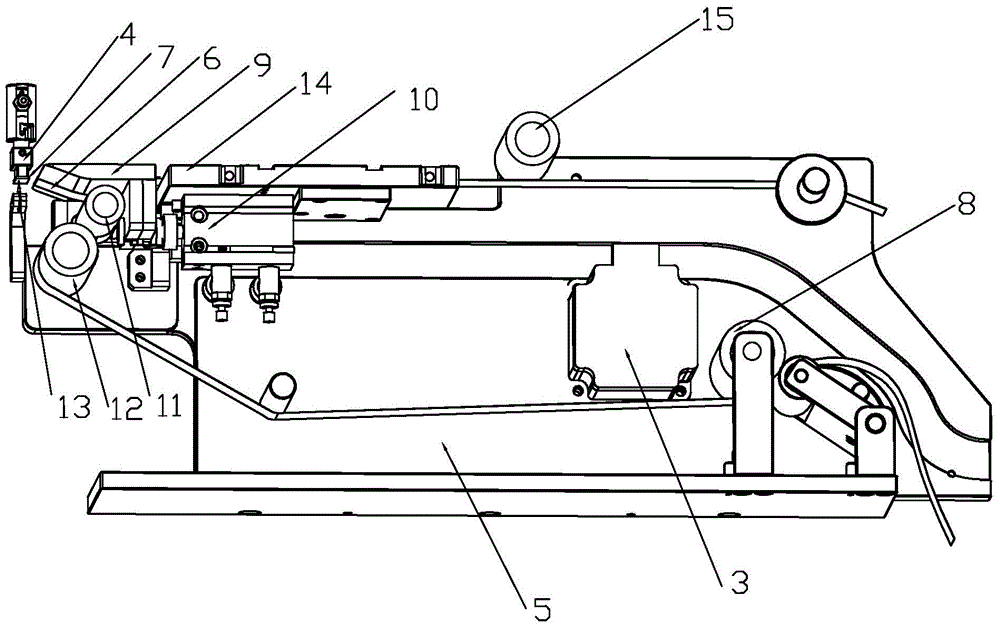

[0023] see figure 1 , a kind of automatic stripping and retrieving device of the present invention, comprises stripping mechanism 1, retrieving mechanism 2 and control mechanism 3, and control mechanism 3 is used for controlling stripping mechanism 1 and retrieving mechanism 2, and retrieving mechanism 2 is provided with Above the stripping mechanism 1.

[0024] Wherein, the feeding mechanism 2 includes a movable material suction nozzle 4, the stripping mechanism 1 includes a stripping table 5 and a material belt 6, and a plurality of materials 7 are pasted on the material belt 6 at the same interval, and the stripping table 5 is provided with a motor Drive winding wheel 8, stripping knife 9, horizontal drive cylinder 10 and roller assembly 16, stripping knife 9 is movably installed on the horizontal drive cylinder 10, and roller assembly 16 comprises movable roller 11 and fixed roller 12, wherein, movable The roller 11 is arranged below the stripping knife 9 and moves toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com