Suction cup type stacking machine

A stacker and suction cup technology, which is applied in the field of suction cup stackers, can solve the problems of easily damaged items and insufficient grasping fastness, and achieve the effect of firmness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

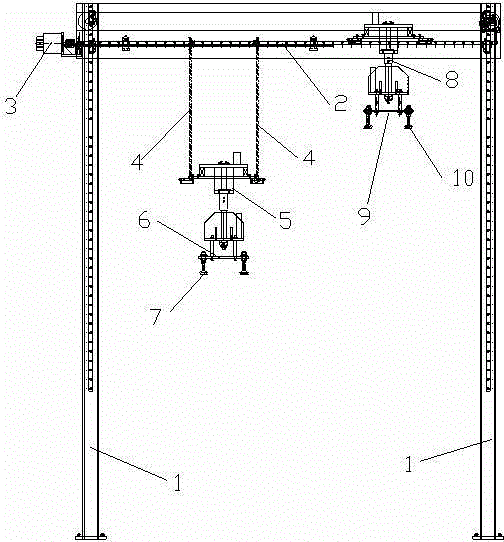

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, a suction cup stacker includes four poles 1, a top plate 2 is fixed between the four poles 1, and the height of the top plate 2 can be adjusted relative to the poles 1. A rotary cylinder 5 is fixed below the top plate 2 , and a first support plate 6 is fixedly connected to the bottom of the rotary cylinder 5 , and two rows of first suction cups 7 are arranged on the lower surface of the first support plate 6 . By arranging a suction cup under the top plate 2 that can move up and down, the goods can be grasped in the form of a suction cup, not only will not damage the goods, but also the firmness of grasping is more reliable. Moreover, the group of suction cups is connected by the rotating cylinder 5, and the angle of the first suction cup 7 can be rotated according to needs to meet different grabbing needs.

[0013] The bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com