A kind of interlayer graphite production equipment

A technology of intercalated graphite and equipment, which is applied in the field of interlayer graphite preparation equipment, can solve the problems of large electrolyte consumption and large power consumption, and achieve the effect of high manufacturing efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in combination with specific embodiments.

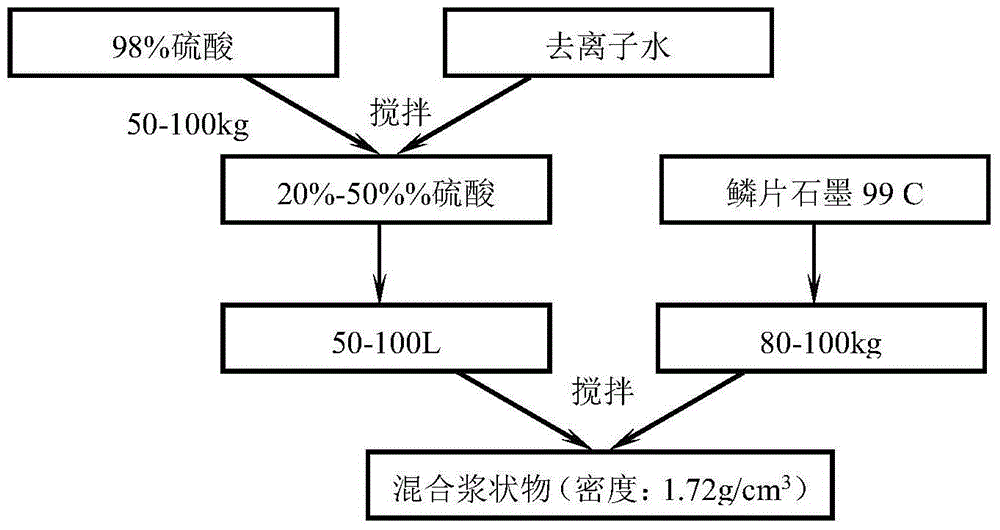

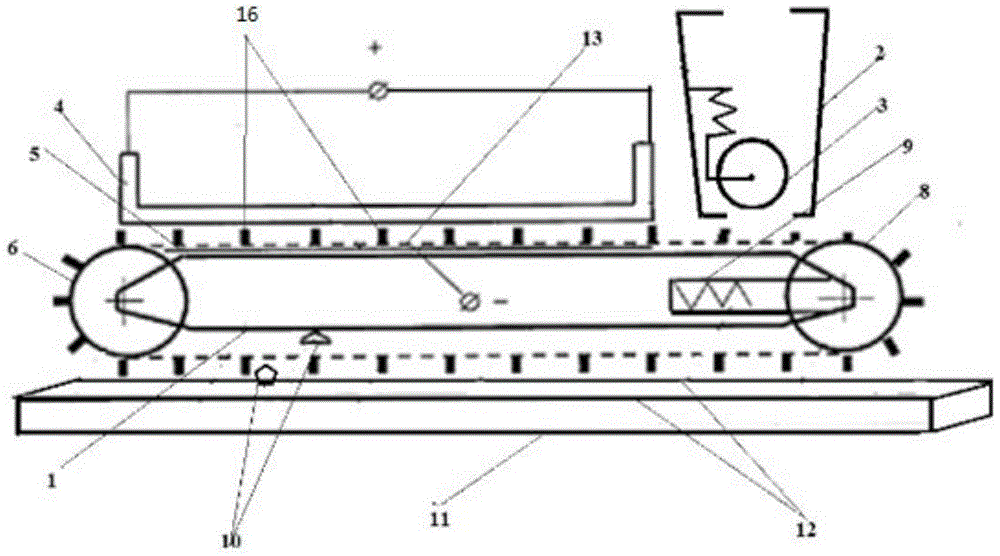

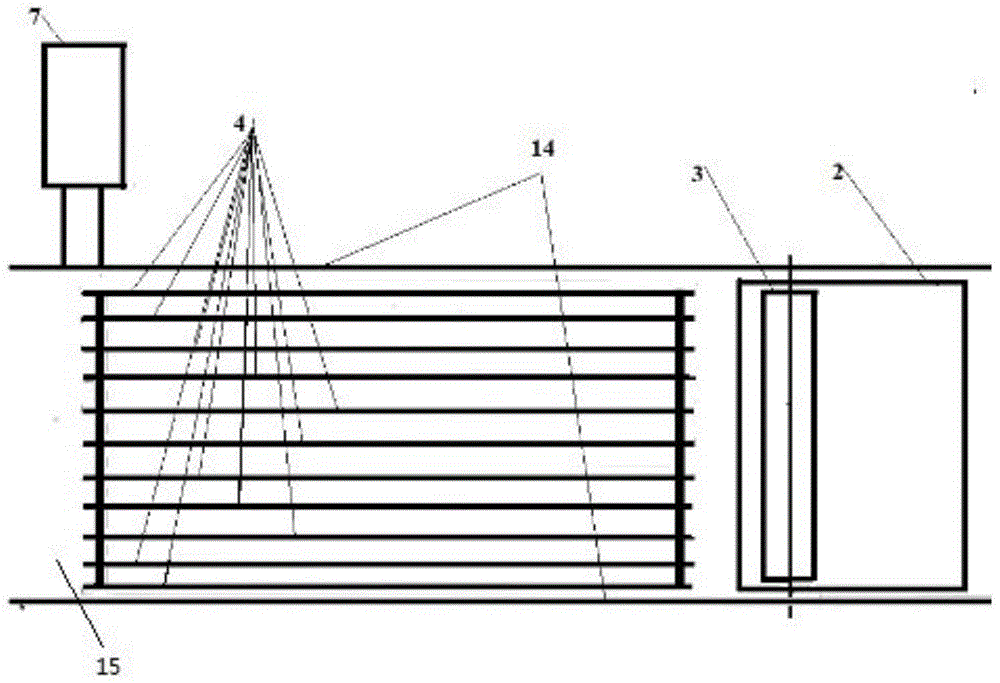

[0017] The preparation method of interlayer graphite of the present invention, graphite and the sulfuric acid that concentration is 30%-94% according to (0.5-1.0cm 3 ): 1 g was stirred to prepare a mixture. Such as figure 1 As shown, it is the preferred preparation method of the mixture: use 50kg-100kg of 98% concentration of sulfuric acid and 50kg-100kg of deionized water to stir to generate a 20%-50% concentration of sulfuric acid solution, take 50-100L, and carbon content of 99% 80-100kg of flake graphite is stirred to make a density of 1.72g / cm 3 Put the mixture into the connecting pipe 2 for carrying, enter the cross-section of the mobile separator 13, use the horizontal adjustment roller 3 to smooth and adjust the thickness of the mixture, add graphite in the connecting pipe 2 Suspension, as the mobile separator 13 moves, the mixture layer moves below the combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com