A production device for refined dimer acid

A production device and technology of dimer acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of low work efficiency, insufficient separation, environmental pollution, etc., and achieve the effect of simplifying equipment and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings.

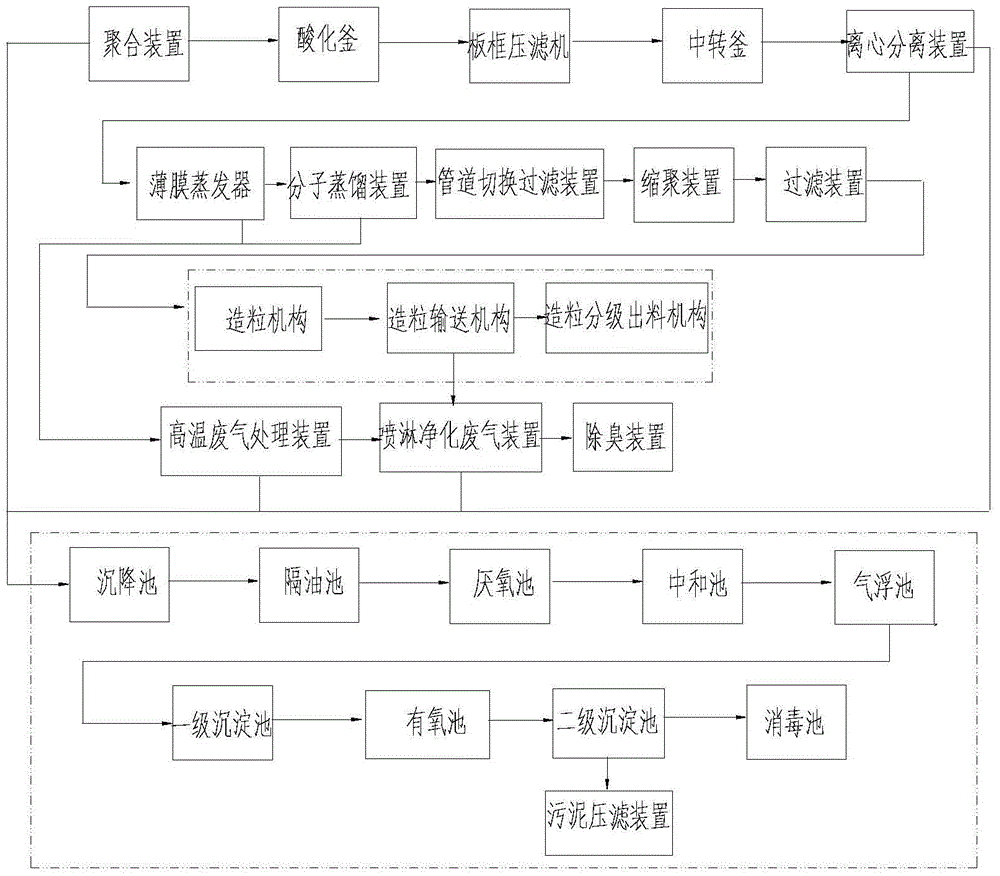

[0033] Such as figure 1 As shown, this embodiment includes a polymerization device, an acidification kettle, a plate and frame filter press, a transfer kettle, a centrifugal separation device, a thin film evaporator, a molecular distillation device, a pipe switching filter device, a polycondensation device, and a filter from front to back according to the process flow. Equipment and granulation system. The production system also includes an exhaust gas treatment device and a wastewater treatment system. The exhaust gas treatment device decomposes and settles the exhaust gas generated during the production process. The wastewater treatment system purifies the wastewater generated during the production process and the exhaust gas treatment device. deal with.

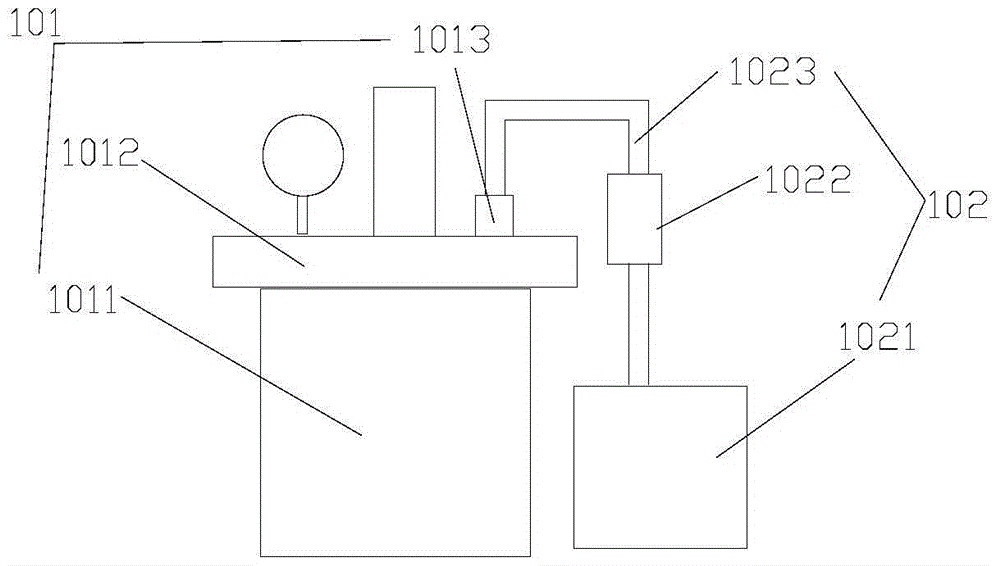

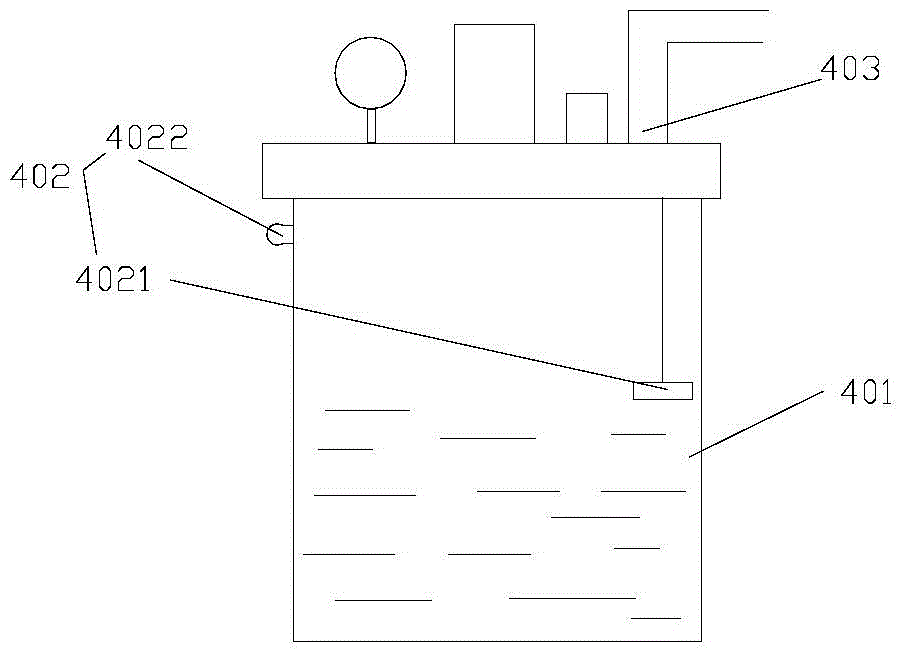

[0034] The acidification kettle, the plate and frame filter press, the thin film evaporator and the molecular distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com