Phosphorus removal material and preparation method thereof

A technology for aggregates and raw materials, applied in the field of phosphorus removal materials and their preparation, can solve problems such as poor phosphorus removal effect and secondary pollution, and achieve the effects of improving efficiency, ensuring mechanical properties, and high phosphorus removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

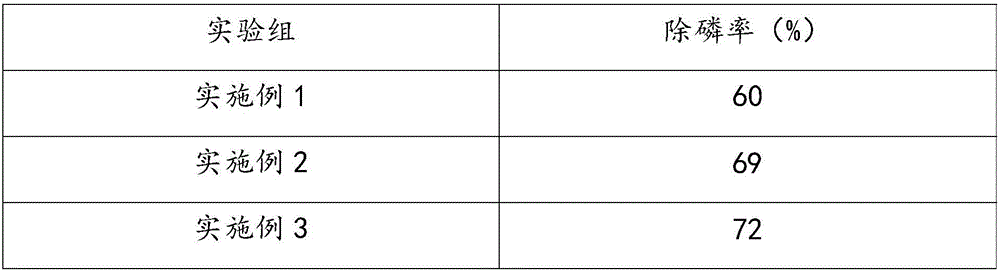

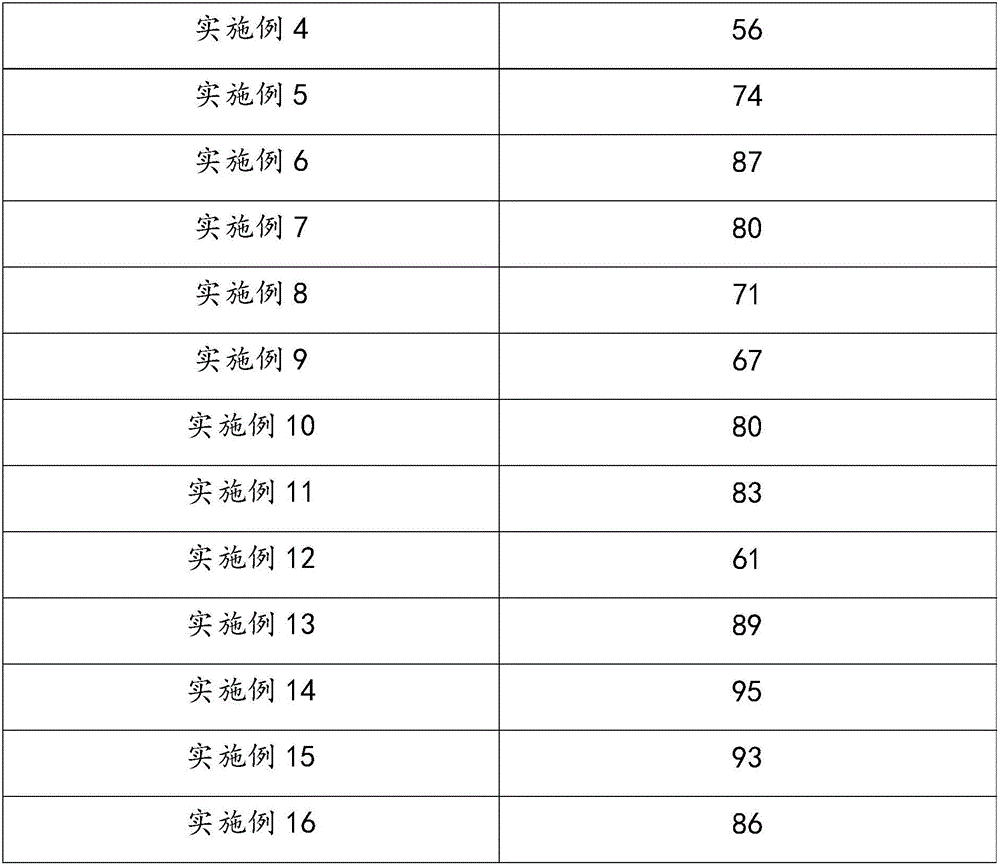

Embodiment 1-4

[0041] (1) Heat the four parts of quartz sand particles with a weight of 100g and a particle size of 6 mesh, 10 mesh, 20 mesh and 30 mesh respectively to 50°C;

[0042] (2) Under heating conditions, add 4g of raw material hydrated aluminum silicate and an appropriate amount of acid anhydride to each group of quartz sand particles, and stir evenly, so that the raw material hydrated aluminum silicate can coat the quartz sand particles;

[0043] (3) After the reaction, the temperature was lowered, and the obtained coated quartz sand particles were crushed and sieved to obtain the phosphorus removal materials of Examples 1-4.

[0044] Wherein, the raw material quartz sand particle is 6 meshes as embodiment 1, the raw material quartz sand particle is 10 meshes is embodiment 2, the raw material quartz sand particle is 20 meshes is embodiment 3, the raw material quartz sand particle is 30 meshes is embodiment 4.

Embodiment 5-8

[0046] (1) Heat the four parts of quartz sand particles with a weight of 100g and a particle size of 6 mesh, 10 mesh, 20 mesh and 30 mesh respectively to 400°C;

[0047] (2) under heating conditions, add 4g of raw material ferric silicate hydrate and appropriate amount of triethylamine to the quartz sand particles, and stir evenly, so that the raw material ferric silicate hydrate can coat the quartz sand particles;

[0048] (3) After the reaction, the temperature was lowered, and the obtained coated quartz sand particles were crushed and sieved to obtain the phosphorus removal materials of Examples 5-8.

[0049] Wherein, the raw material quartz sand particle is 6 meshes is embodiment 5, the raw material quartz sand particle is 10 meshes is embodiment 6, the raw material quartz sand particle is 20 meshes is embodiment 7, the raw material quartz sand particle is 30 meshes is embodiment 8.

Embodiment 9-12

[0051] (1) Heat the four parts of quartz sand particles with a weight of 100g and a particle size of 6 mesh, 10 mesh, 20 mesh and 30 mesh respectively to 100°C;

[0052] (2) under heating condition, add 4g raw material calcium carbonate and appropriate amount of hexamethylenetetramine to the quartz sand particle, and stir evenly, make raw material calcium carbonate can coat described quartz sand particle;

[0053] (3) After the reaction, the temperature was lowered, and the obtained coated quartz sand particles were crushed and sieved to obtain the phosphorus removal materials of Examples 9-12.

[0054] Wherein, the raw material quartz sand particle is 6 meshes is embodiment 9, the raw material quartz sand particle is 10 meshes is embodiment 10, the raw material quartz sand particle is 20 meshes is embodiment 11, the raw material quartz sand particle is 30 meshes is embodiment 12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com