Washing machine provided with vertical drums

A washing machine and vertical drum technology, applied in the field of washing machines, can solve the problems of low stain removal and small turnover of laundry, and achieve the effects of low manufacturing cost, enhanced turnover force, and promotion of turnover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

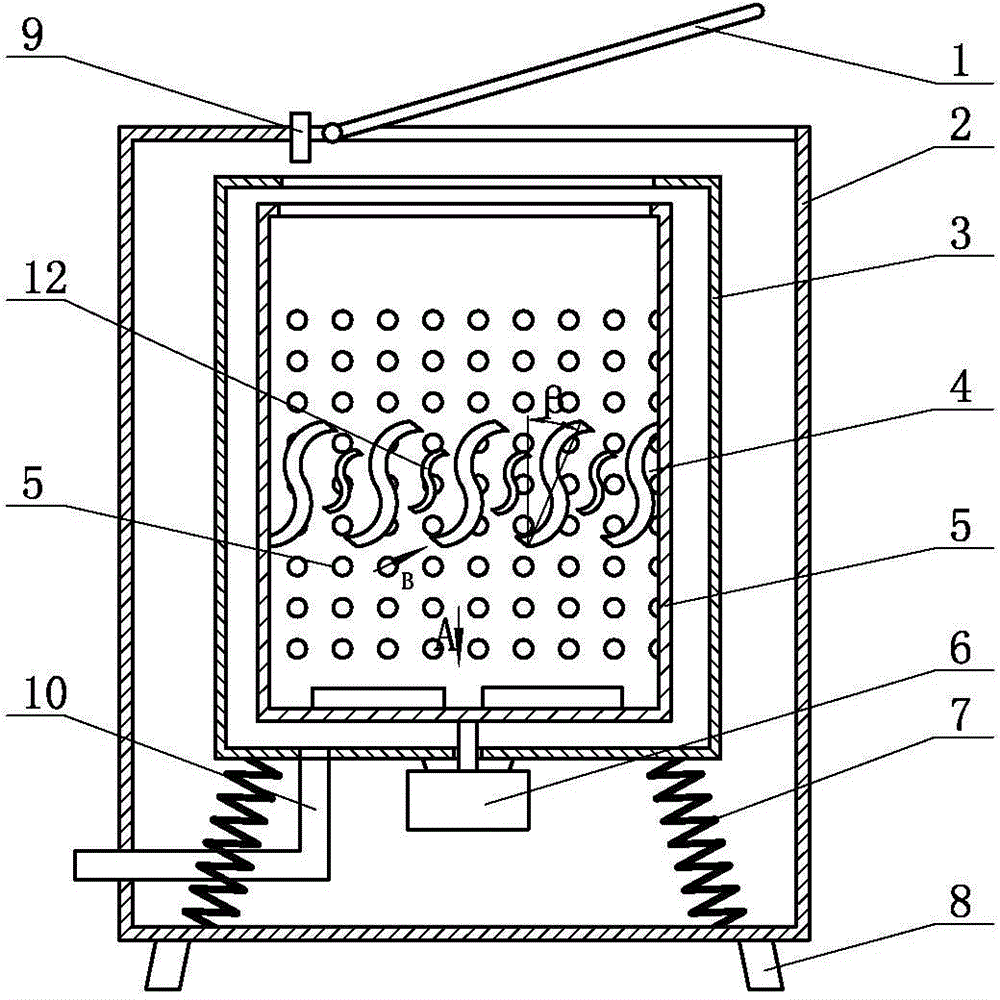

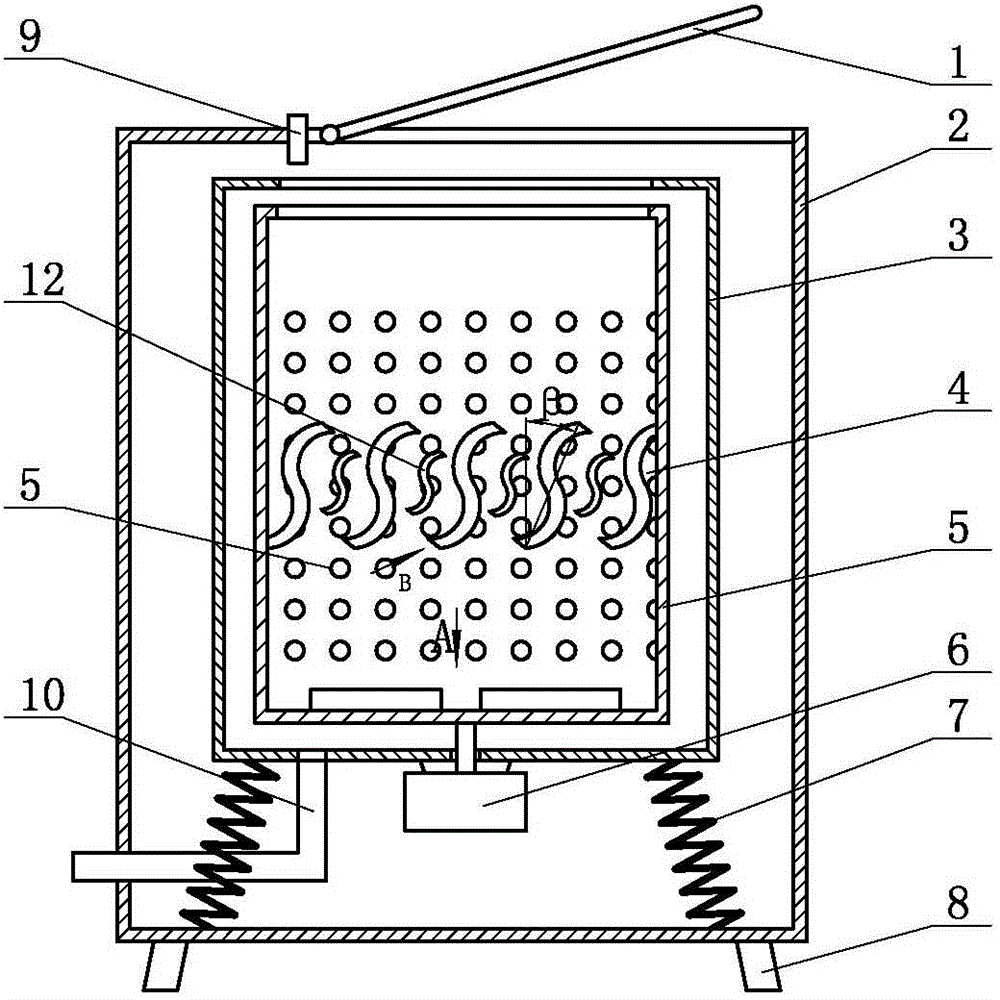

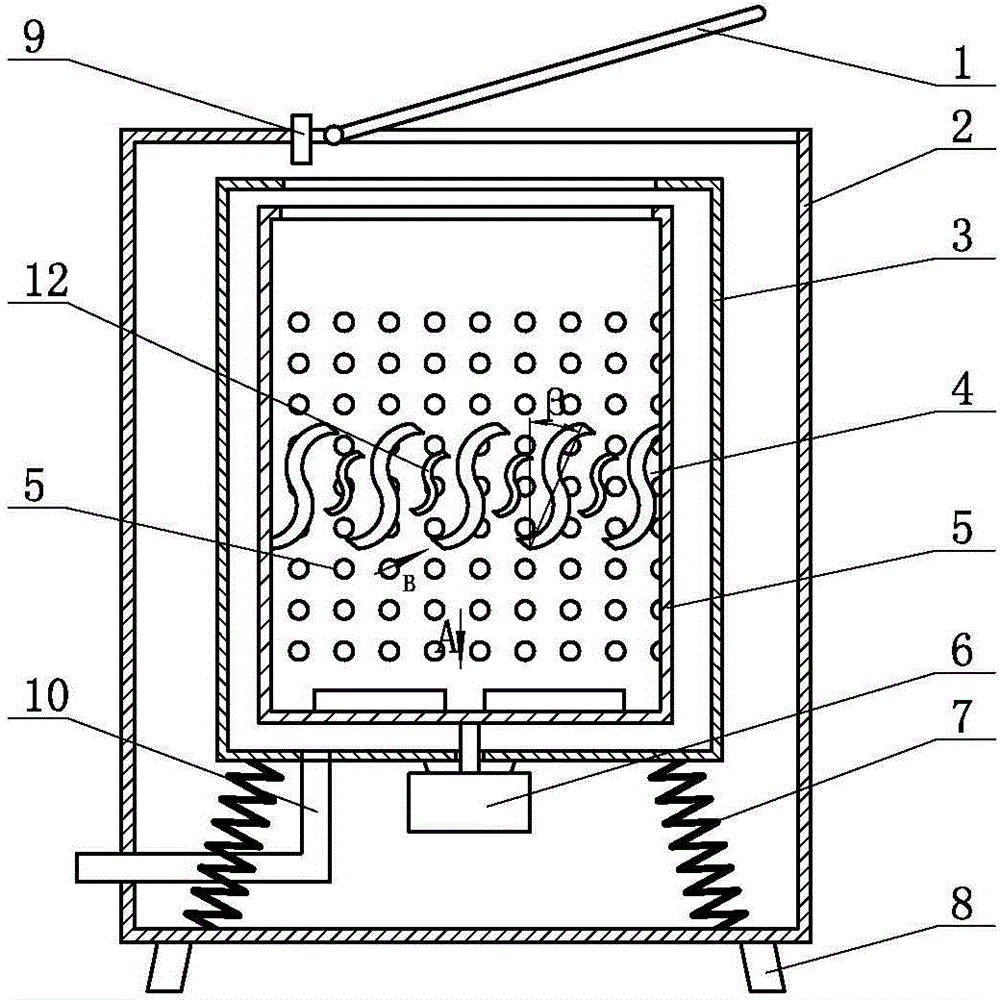

[0009] A vertical drum washing machine, such as figure 1 , figure 2 and image 3 As shown, it includes a shell 2, an outer cylinder 3 and an inner cylinder 5 are arranged in the outer shell 2, a driving motor 6 is installed at the bottom of the outer cylinder 3, and the output shaft of the driving motor 6 is connected to the bottom of the inner cylinder 3. The inner cylinder 3 has a bottom and side integral structure, and the structure has high stability. Several washing ribs 4 are evenly arranged on the inner wall of the inner cylinder 3, and the washing ribs 4 are S-shaped, horizontally V-shaped or strip-shaped. The outer cylinder 3 and the shell 2 can be connected by a spring 7, and the spring 7 has a supporting effect on the outer cylinder 3, and can play a role of buffering and shock absorption during the use of the outer cylinder 3. Among the figure, 9 is a water inlet, 1 is a door cover, 10 is a drain pipe, 8 is a supporting foot, and 11 is a through hole.

[0010]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com