Corrugated steel baseplate and concrete composite beam

A corrugated steel and concrete technology, which is applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of complex construction technology, and achieve the effects of convenient construction, improved stress, and ingenious conception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

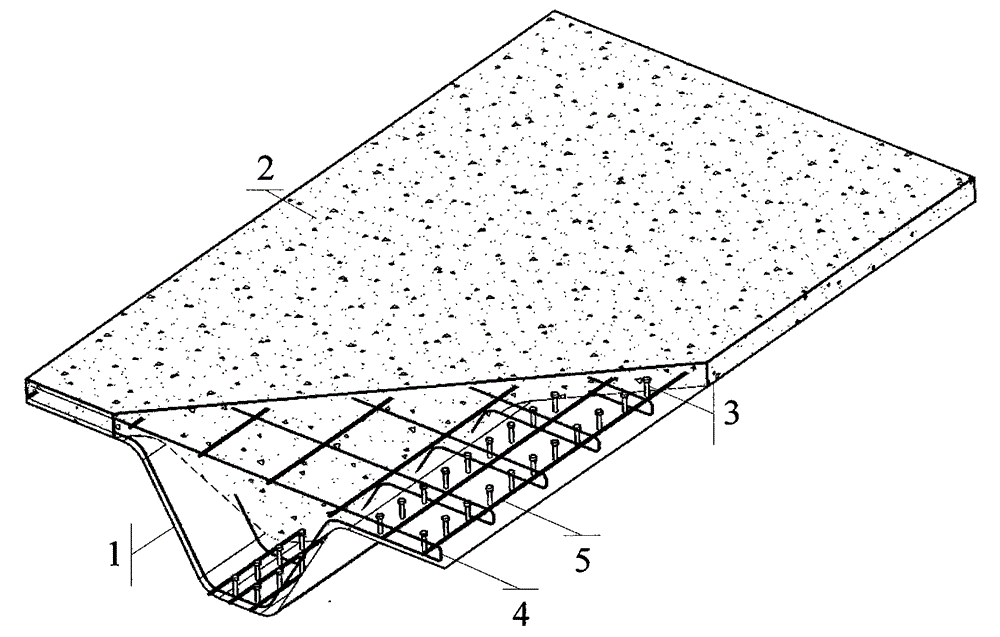

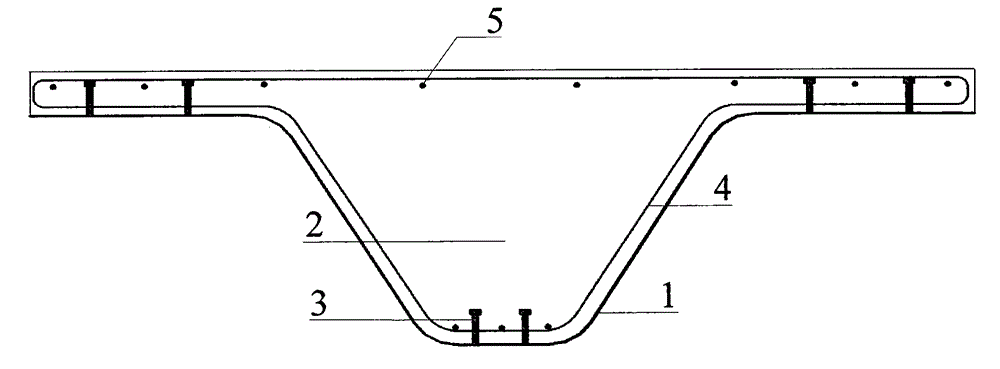

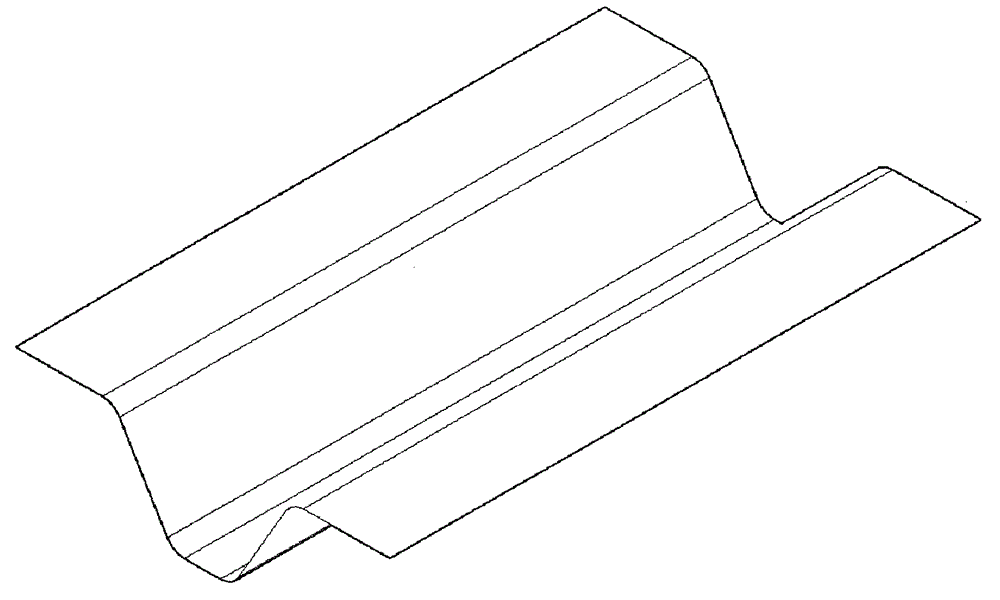

[0024] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the corrugated steel bottom plate-concrete composite beam includes: corrugated steel bottom plate 1, concrete plate 2, shear nails 3, stirrups 4 and longitudinal steel bars 5; corrugated steel bottom plate 1 is located at the lower edge of the corrugated steel bottom plate-concrete composite beam , set shear nails 3 on the upper surface of corrugated steel base plate 1, stirrups 4 and longitudinal steel bars 5 are bound to each other to form a steel mesh, and concrete slab 2 is poured on the upper edge of the corrugated steel base plate 1, wrapping the shear nails 3, hoop 4 and longitudinal reinforcement 5.

[0025] The corrugated steel bottom plate 1 bears the tensile stress of the lower edge under the bending action, instead of the tensile steel bars, the corrugated steel bottom plate 1 can be used as a formwork when pouring the concrete slab 2, which reduces the construction workload. , the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com