sports floor with tight fit

A floor and compact technology, applied in the direction of elastic floor, can solve the problems that affect the effect and comfort of use, deformation, and damage to the life of the sports floor, and achieve the effect of simple structure, reduced contact area, and normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The utility model will be further described below in conjunction with accompanying drawing.

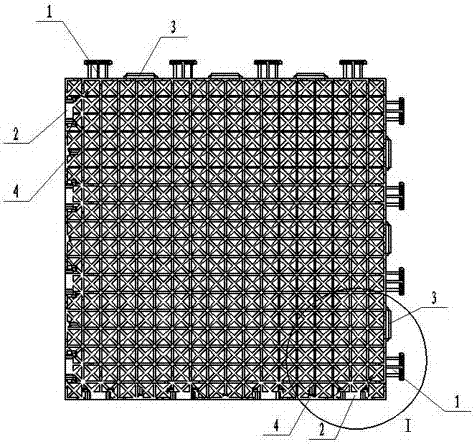

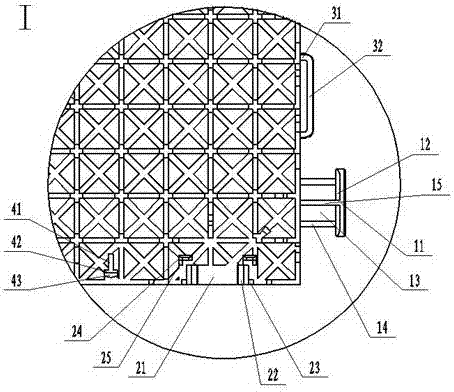

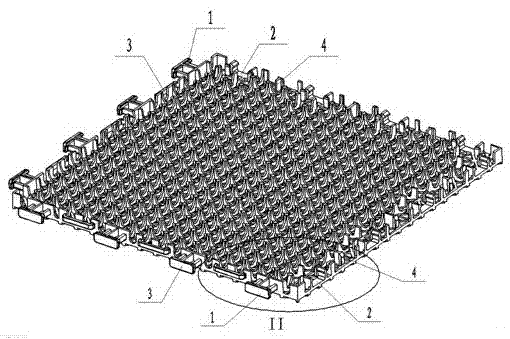

[0029] A sports floor with the function of tight fit, comprising two sets of clips 1 respectively arranged on two adjacent sides of the sports floor and two sets of clips respectively arranged on the other two adjacent sides of the sports floor to cooperate with the two sets of clips 1 Seat 2, chuck 1 is provided with first plane 13, and deck 2 is provided with second plane 21; It also includes two groups of elastic struts 4 for blocking positioning and two groups of elastic struts 4 for blocking positioning respectively arranged on the two adjacent sides of the sports floor and for air temperature As the gap of the sports floor decreases, the two groups of elastic arms 3 that contact the elastic pillar 4 to provide elastic force to push the sports floor away and keep the sports floor in close contact, and the two sets of elastic arms 3 arranged in the deck 2 for When the tempe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap