Revolving wall for on-site safety management

A safety management and turnover technology, applied in the direction of fences, building types, buildings, etc., can solve the problem that the fence cannot be reused, and achieve the effects of low possibility of the fence toppling over, easy disassembly, and reduced bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

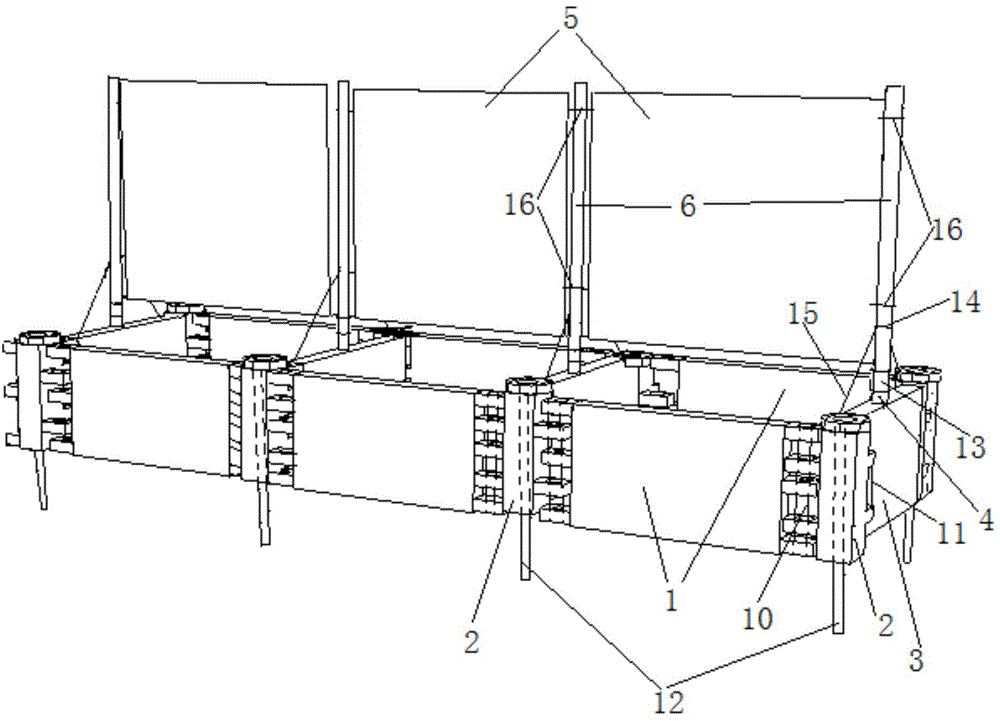

[0026] The present invention is an on-site safety management turnover wall, the structure is as follows figure 1 shown, including a base portion and a wall portion attached to the base portion.

[0027] The base part includes a vertical plate a1 , a communication column 2 , a vertical plate b3 , a connecting rod a10 , a connecting rod b11 , and a foundation rod 12 .

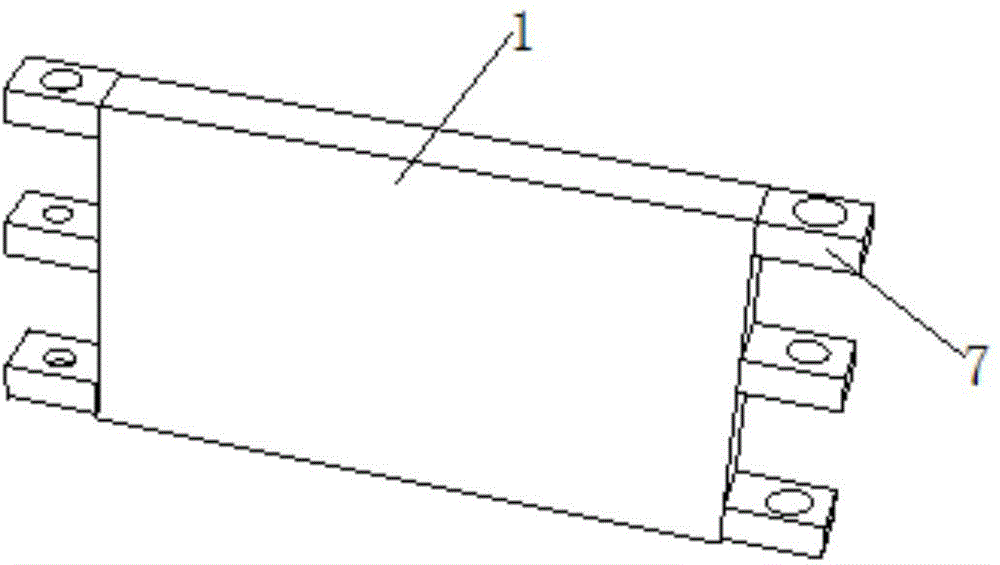

[0028] The structure of the vertical plate a1 is as follows figure 2 As shown, the vertical plate a1 is a rectangular thin plate made of reinforced concrete. Several connecting blocks a7 are provided on the two sides of the vertical plate a1 and the connecting column 2, and the connecting blocks a7 are all provided with through holes.

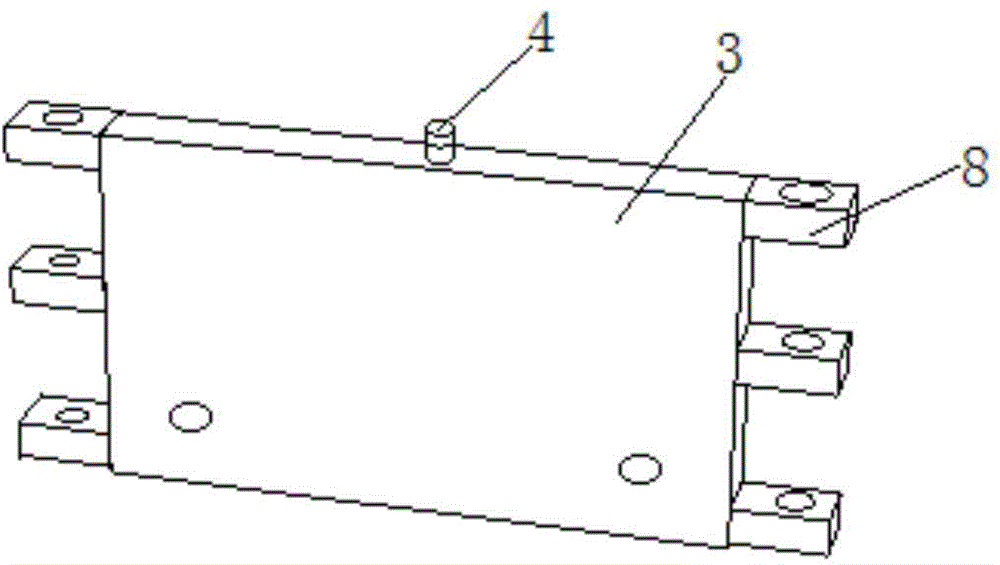

[0029] The structure of the vertical plate b3 is as follows image 3 As shown, the vertical plate b3 is a rectangular thin plate made of reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com