Wind driven generator rotating blade and wind driven generator adopting the same

A technology of wind generators and rotating blades, which is applied in the direction of wind turbines, wind turbines, and wind motors at right angles to the wind direction, which can solve the problems of severe blade shaking, long residence time, and high safety hazards, and achieve reduced shaking and enhanced wind power. Stability, the effect of enhancing balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

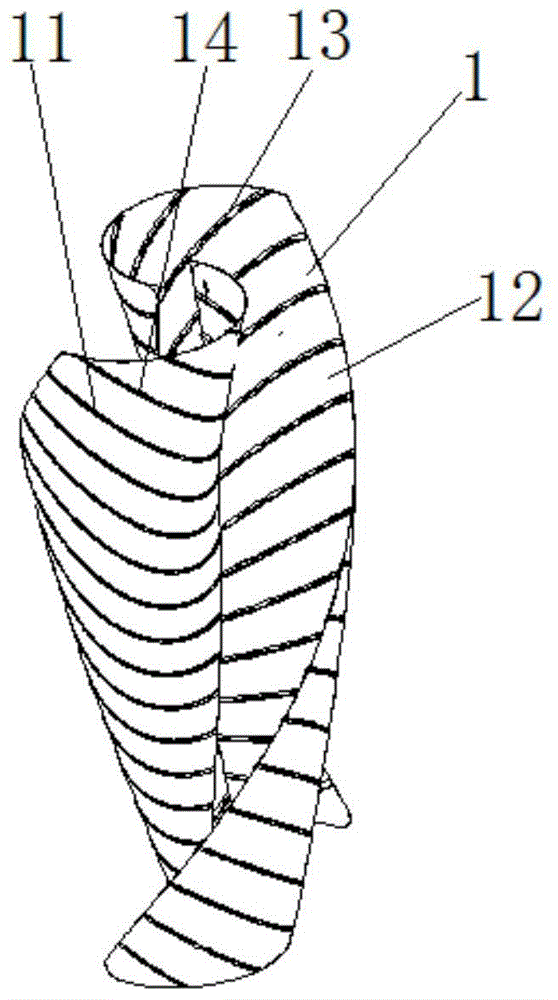

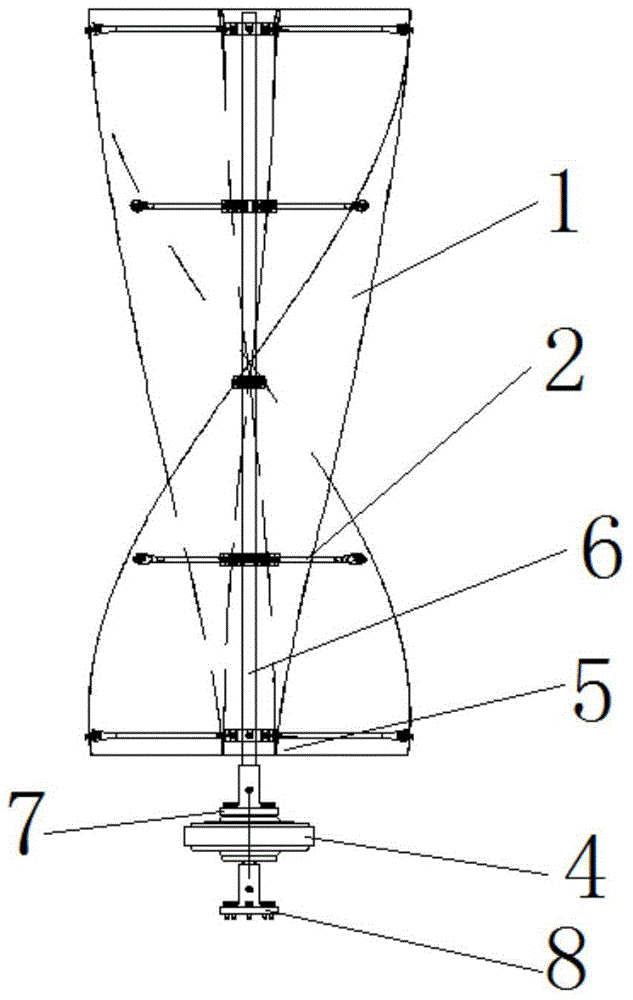

[0020] Such as figure 1 A rotating blade of a wind power generator is shown, which includes an integrally formed helical blade body 1, and on the back of the blade body 1, a plurality of reverse wind guiding grooves 11 at a certain angle to the horizontal direction are distributed at a certain interval. On the front of the blade body 1 between the positions of the reverse wind guide grooves 11, a plurality of transverse positive wind guide grooves 12 are formed, and in the reverse wind guide grooves 11, several holes penetrating the blade body are arranged. Reverse ventilation holes 13, when the wind blows from the front of the blade body 1, it acts on the positive wind guide groove 12, pushing the blade body 1 to rotate, while the reverse resistance wind will move to the reverse wind guide on the back of the blade body 1 In the groove 11 , it leaves the fan blade body 1 through the reverse ventilation hole 13 in the reverse wind guide groove 11 .

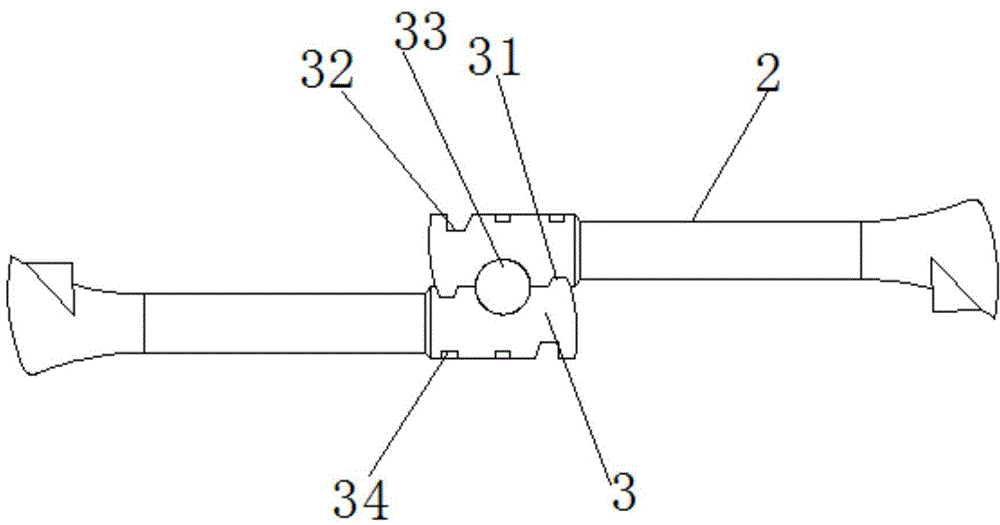

[0021] Such as image 3 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com