Multifunctional control valve

A multi-functional control valve and valve body technology, applied in the direction of control valve, functional valve type, multi-way valve, etc., can solve the problems of unstable water temperature at the outlet of the mixing valve, reducing the service life of the water storage container, and hot water outflow, etc. Achieve the effect of avoiding user's property loss, simple structure and reducing work pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

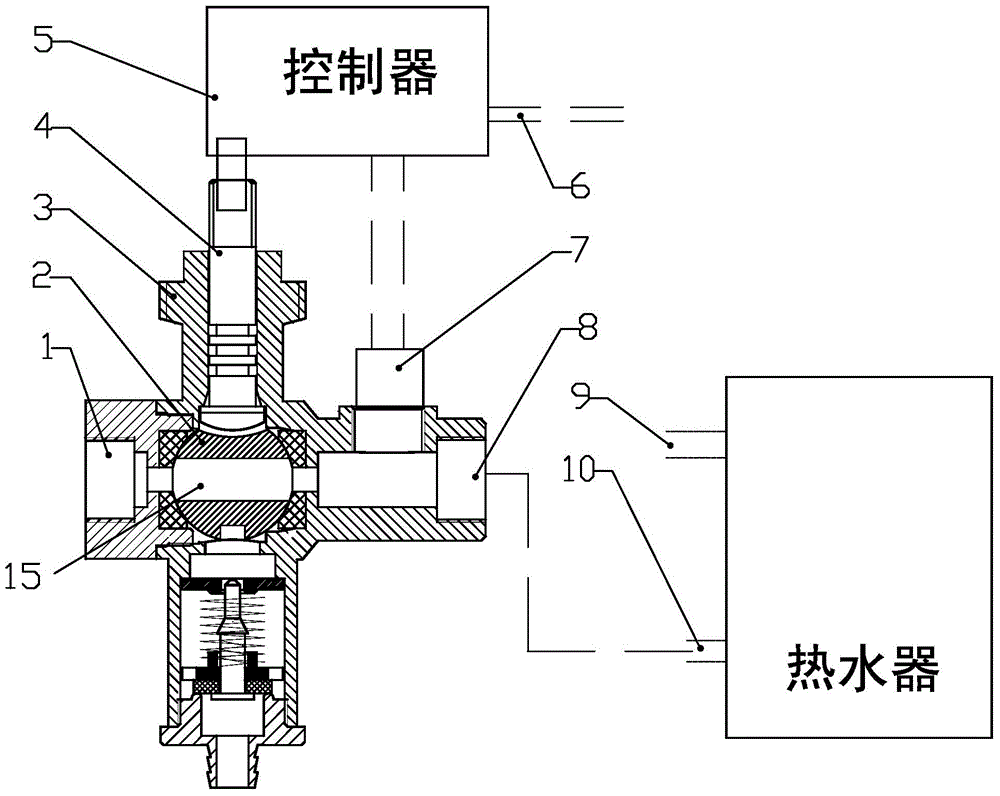

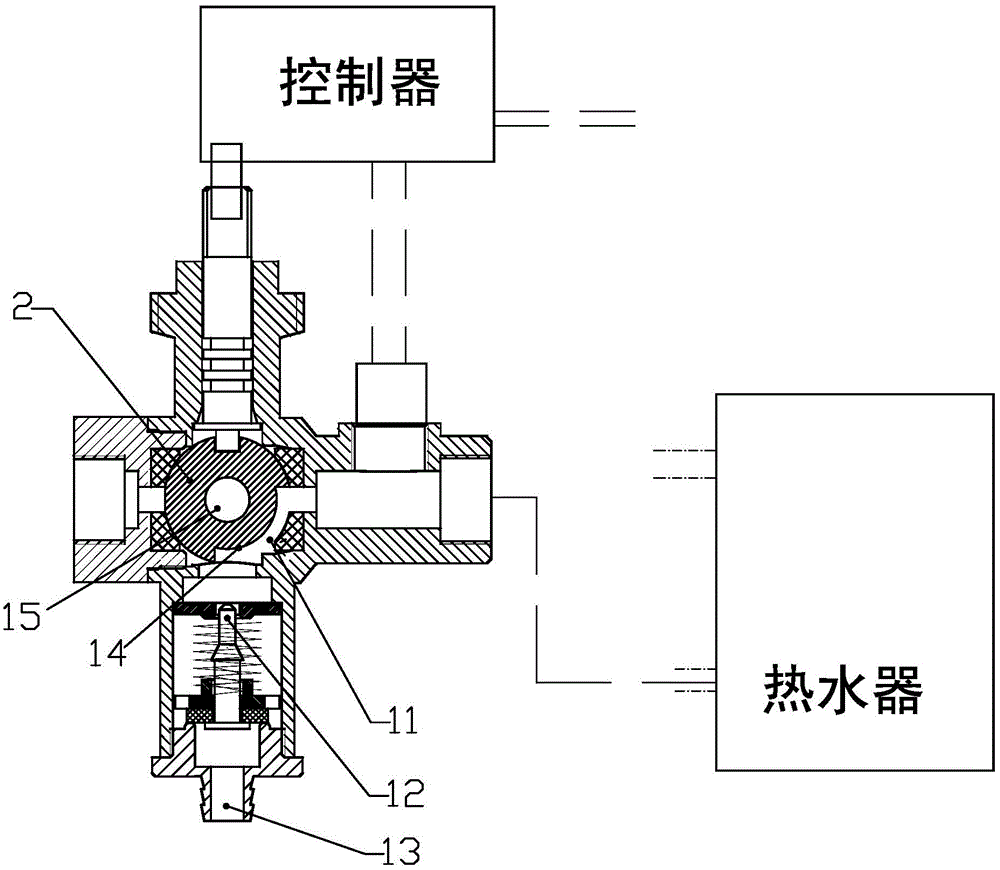

[0017] The following is attached Figure 1-2 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

[0018] Such as figure 1 As shown, the multifunctional control valve includes a valve body 3, and a cavity for installing a valve ball 2 is provided in the valve body. The valve ball 2 is installed in the cavity, and the valve ball 2 can be placed in the cavity under the action of external force. turn. A valve water inlet 1 is arranged on the left side of the valve body, and the valve water inlet 1 communicates with the tap water pipe. The right side of the valve body is provided with a valve water outlet 8, and the valve water outlet 8 communicates with the cold water inlet of the water heater. The valve water inlet 1 and the valve water outlet 8 are at the same horizontal position, and the valve ball 2 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com