Test bed for leaf spring for automobile suspension

The technology of a leaf spring and a test bench is applied to the test bench of an automobile suspension leaf spring, and the field of the test bench in the design and manufacture of the leaf spring of the automobile suspension, which can solve the deviation of the test accuracy and cannot simulate the working state of the leaf spring. and other issues to achieve the effect of improving efficiency and reducing development costs and cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The leaf spring test bench of the present invention is an innovation for possible problems in the experimental data of the existing traditional leaf spring test bench.

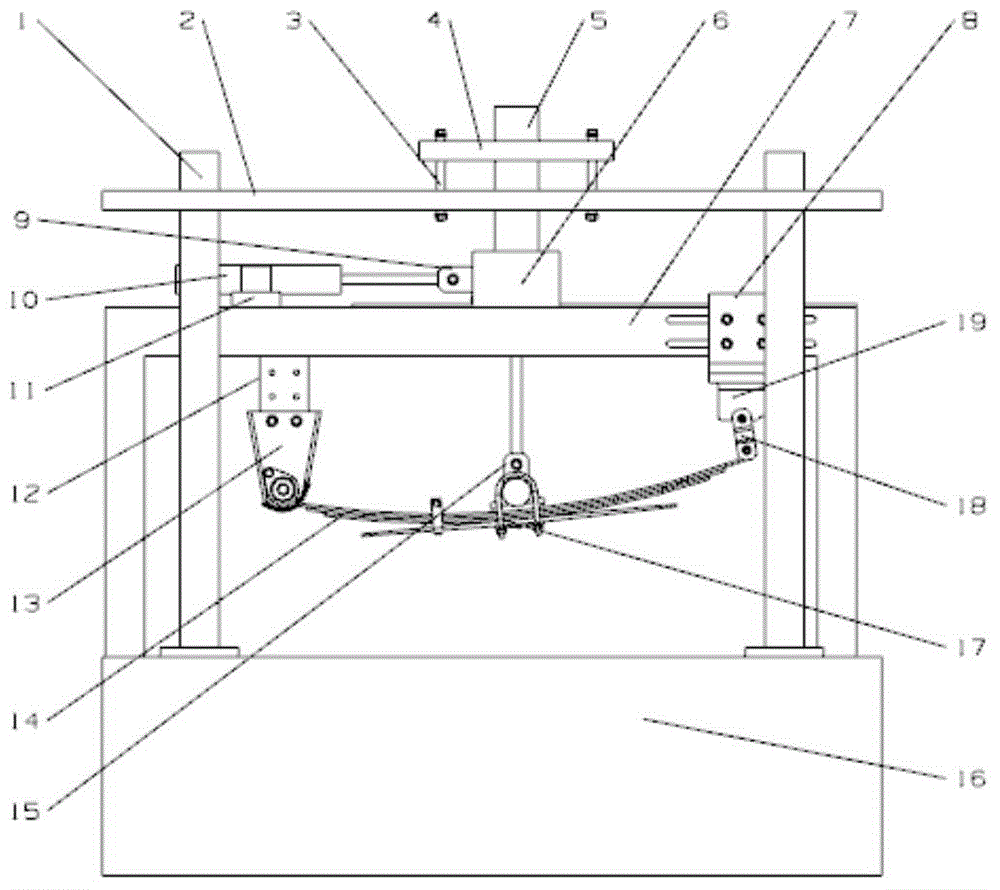

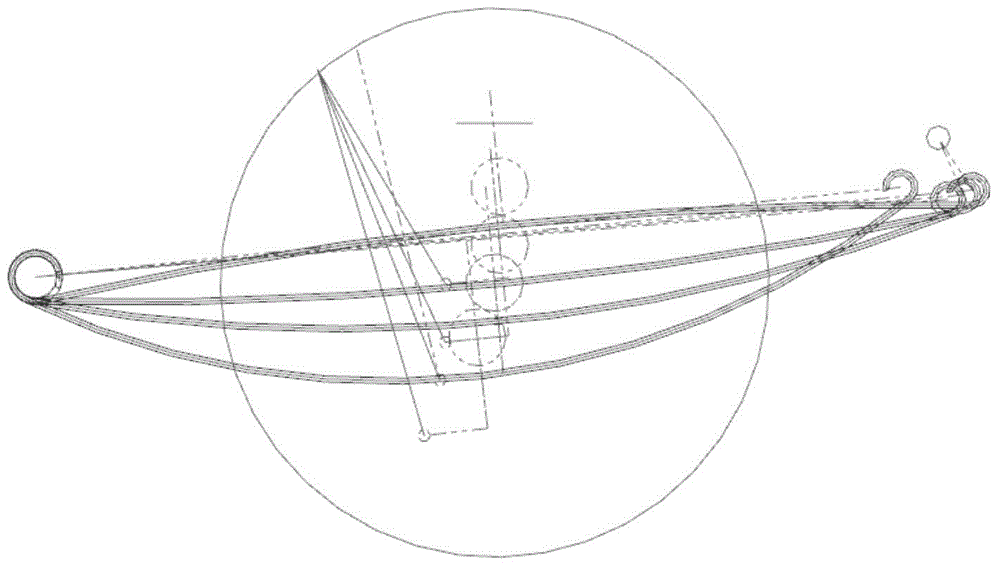

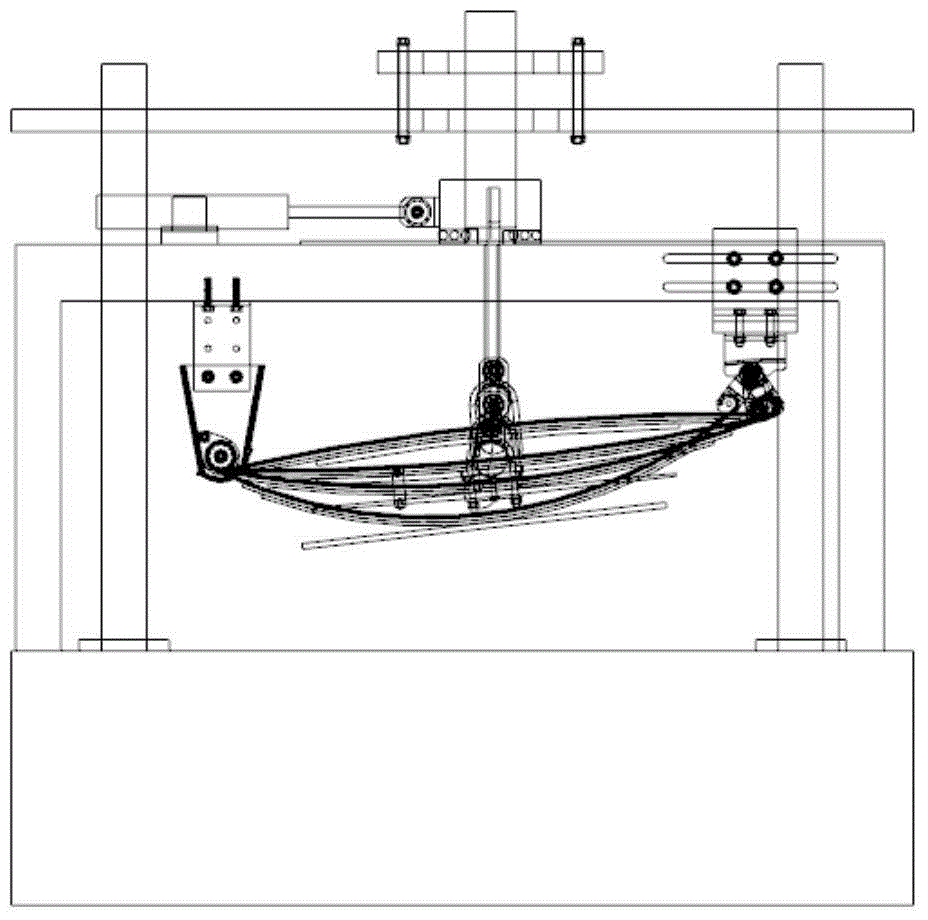

[0031] Such as figure 1 Shown is the structure diagram of the leaf spring test bench of the present invention, the test bench can be applied to various types of leaf springs, and leaf springs of different lengths can be installed in the width direction of the bench. Such as Figure 4 As shown, the coordinate system of the leaf spring test bench, the X direction, the Y direction and the Z direction represent the transverse, longitudinal and vertical directions respectively.

[0032] Such as figure 1As shown, the automobile suspension leaf spring test bench of the present invention includes a main console 16, a column 1 on the main console 16 and a test bench frame bearing beam 7, and the main loading hydraulic cylinder fixed bracket 2 is located at the column 1 The upper part of the main loading hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com