Machine tool thermal error compensation method based on augmented naive Bayes network

A technology of Bayesian network and compensation method, which is applied in the field of machine tool thermal error compensation based on enhanced naive Bayesian network, can solve the problems that the model accuracy and robustness are difficult to meet the high-speed and high-precision actual processing requirements, and achieve Easy to predict in real time, ensure accuracy, and improve the effect of machine tool processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

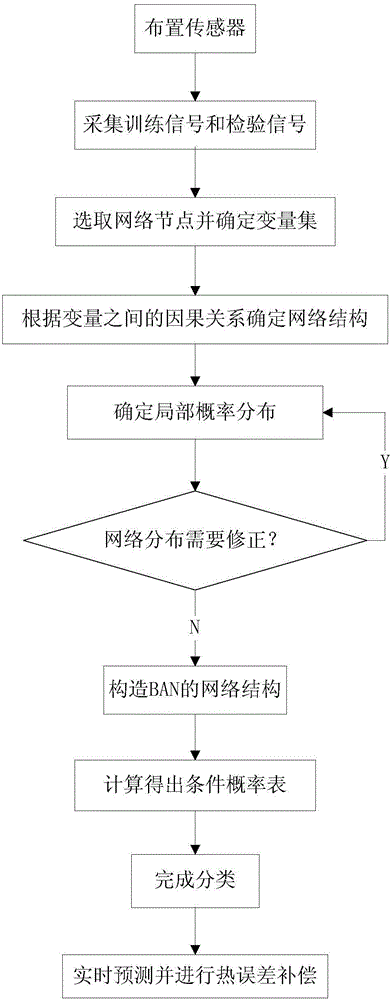

[0043] combine figure 1 As shown, the method of thermal error compensation of machine tools based on enhanced naive Bayesian network includes the following steps:

[0044] Step 1, a plurality of sensors are arranged near the thermal key point on the machine tool; usually a plurality of temperature sensors and position sensors are arranged on the machine tool, and the sensor arranged near the thermal key point is a temperature sensor, and the arrangement of the sensor is determined by those skilled in the art. According to the conventional methods mastered, the layout position of the temperature sensor is generally based on the temperature that can accurately measure the temperature of the thermal key point; more than two; the thermal key point mainly includes the left bearing, the right bearing, the motor, the guide rail, the workbench and the Y direction. Friction joints,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com