A dynamic modeling method for multi-channel force transmission rotor hub structure

A dynamic modeling, rotor hub technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of not carrying out multi-channel force transmission rotor hub configuration design research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

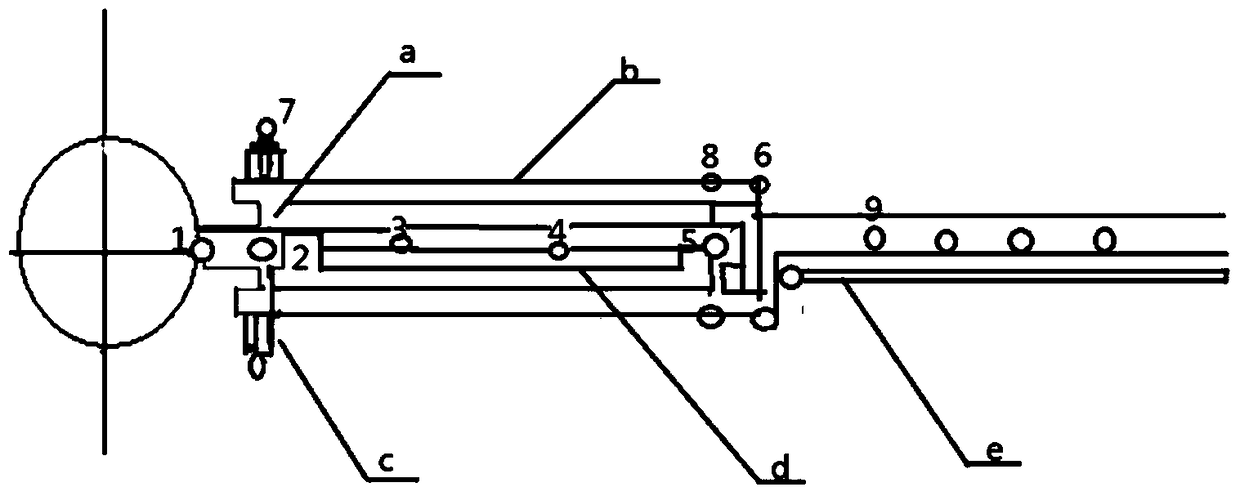

[0023] The method for dynamic modeling of the multi-way power transmission rotor hub structure involved in the present invention will be further described in detail below in conjunction with the accompanying drawings.

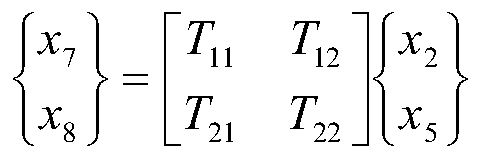

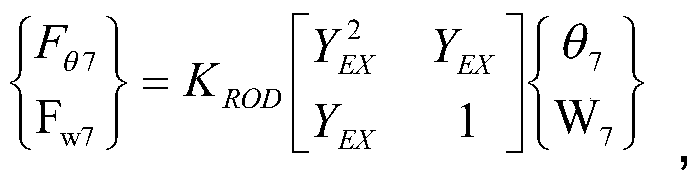

[0024] In the multi-path force transmission rotor hub structural dynamics modeling method of the present invention, the multi-channel force transmission rotor hub structural dynamics finite element modeling is performed first. According to the force transmission, movement and deformation conditions of the components of the propeller hub structure (flexible beam, sleeve, damper and pitch control system), the components are simulated by beam elements, rod elements and elastic damping elements. According to the flexible beam The characteristics of the main force transmission route of the hub with the outer end of the sleeve, the auxiliary force transmission route of the damper and the pitch control system, and the displacement of the connection points between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com