Method for the functional extension of an electric welding apparatus and welding apparatus for carrying out the method

An electric welding machine, functional technology, applied in the direction of arc welding equipment, welding equipment, program control, etc., can solve problems such as impractical and troublesome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

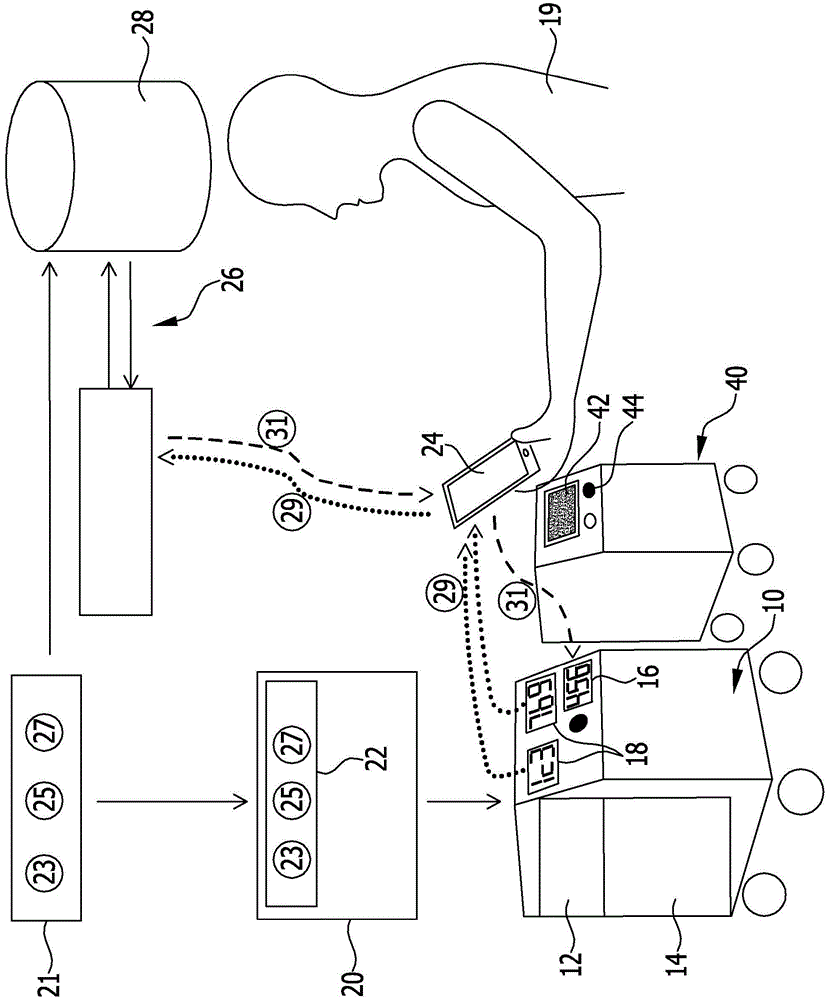

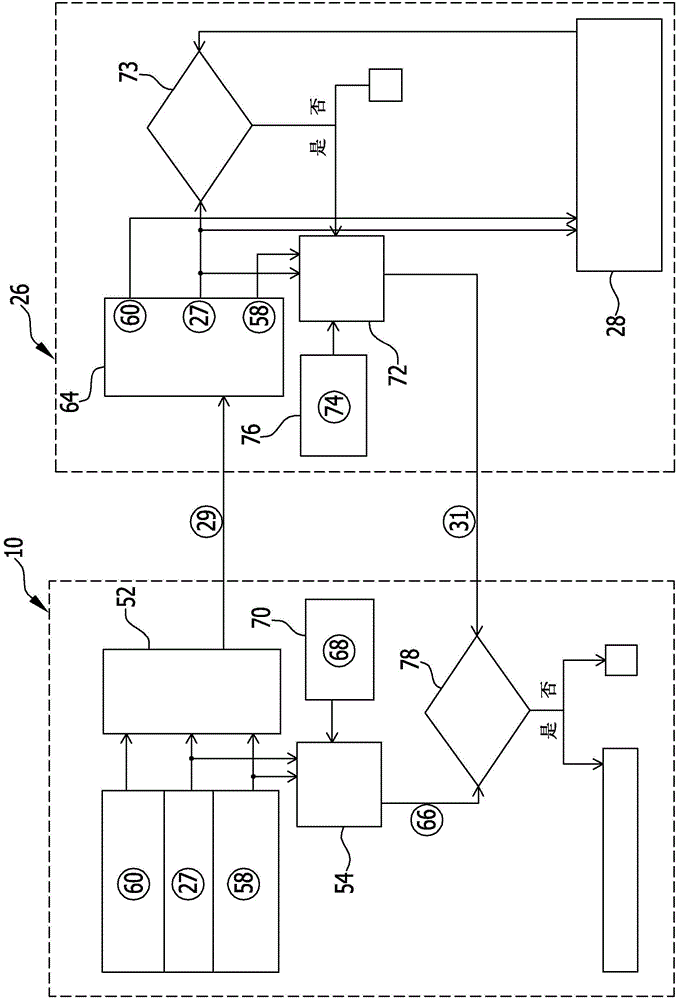

[0049] The drawing schematically shows a first advantageous embodiment of the welding machine according to the invention, which is designated as a whole with the reference numeral 10. The welding machine 10 has a control unit 12 and a power unit 14 which is controlled by the control unit 12 to which welding guns, which are known per se and are therefore not shown in the drawings for a better overview, can usually be connected to the power unit. The welding machine 10 also has an input device 16 and a display device 18 for inputting control instructions and software programs. In the illustrated embodiment, the display device 18 has multiple seven-segment displays.

[0050] The user 19 can usually use the welding machine 10 to complete different welding tasks. The user 19 can expand the functions of the welding machine 10. To this end, the user 19 can purchase a storage medium in the form of a memory card 20 in the illustrated embodiment, and the input device 16 can read the memo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com