Mechanism motion demonstrating platform

A demonstration platform and mechanism movement technology, applied in the field of teaching aids, can solve the problems of unable to display mechanism movement forms, no interest, single function, etc., achieve high interactivity and practicability, strong function expansion, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

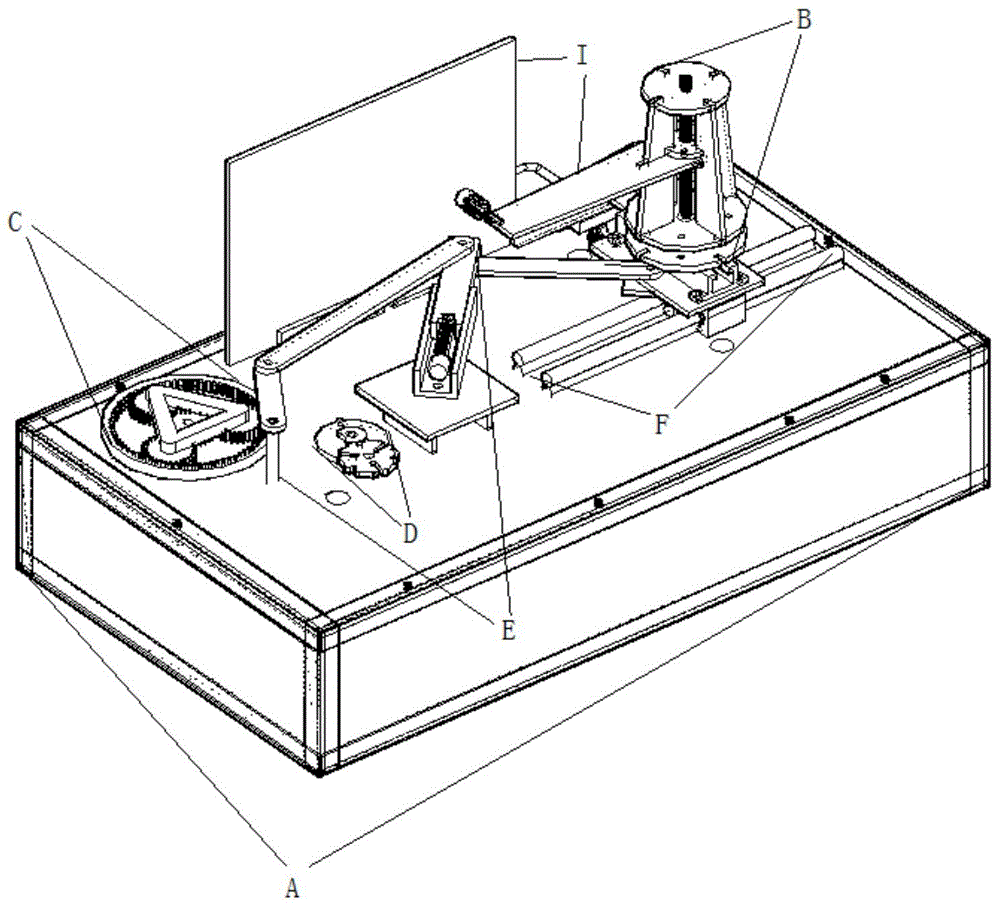

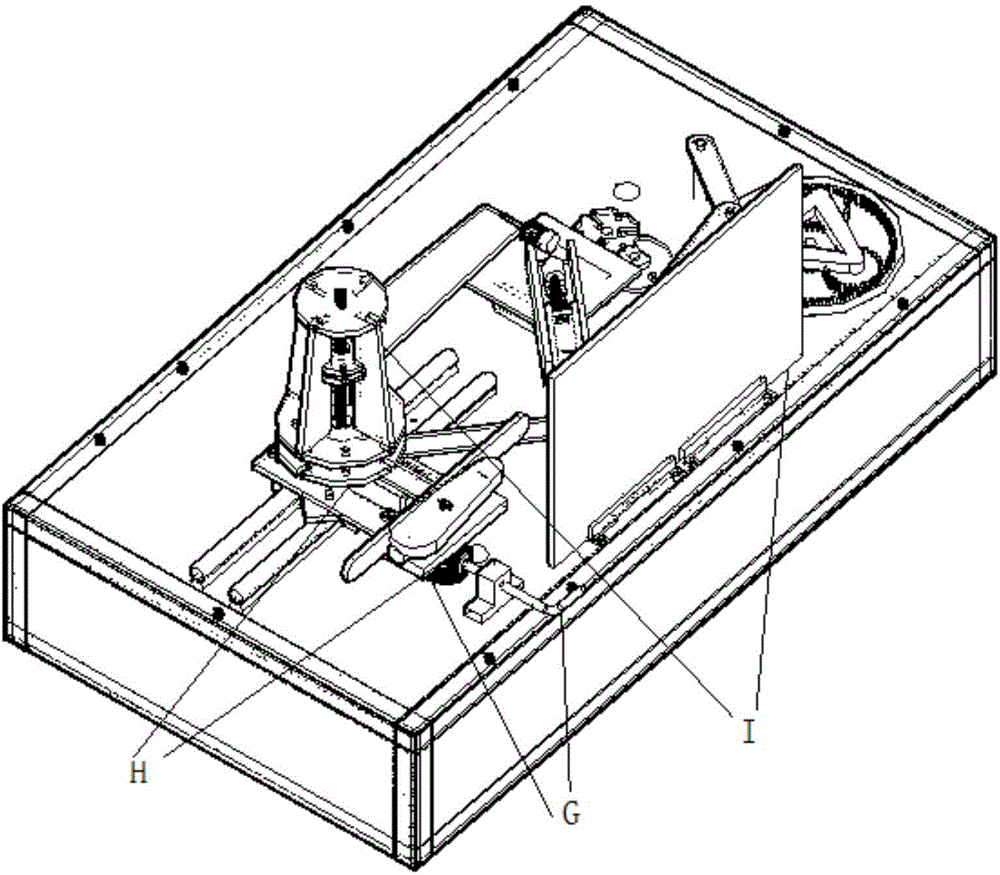

[0023] Figure 1a , 1b Shown is a schematic structural diagram of a mechanism movement demonstration platform according to an embodiment of the present invention, wherein a mechanism movement demonstration platform includes a box A, a screw transmission mechanism B located in the box, a planetary gear mechanism C, a sheave transmission mechanism D, Plane link transmission mechanism E, X-axis guide rail F, bevel gear mechanism G, cam transmission mechanism H seven kinds of basic mechanisms that can be connected, drive circuit (not shown), and motion track feedback unit I, wherein: planar link transmission Mechanism E, screw transmission mechanism B, and cam transmission mechanism H are respectively used as the X, Y, and Z-axis driving mechanisms of the platform. connector connection.

[0024] Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com