HVDC (high-voltage direct current) converter valve water cooling system

A high-voltage direct current and converter valve technology, which is applied in cooling/ventilation/heating transformation, output power conversion devices, electrical components, etc., can solve the problems of large number of water cooling systems and difficult operation, so as to reduce the difficulty of operation and realize Cooling capacity, to achieve the effect of continuous change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

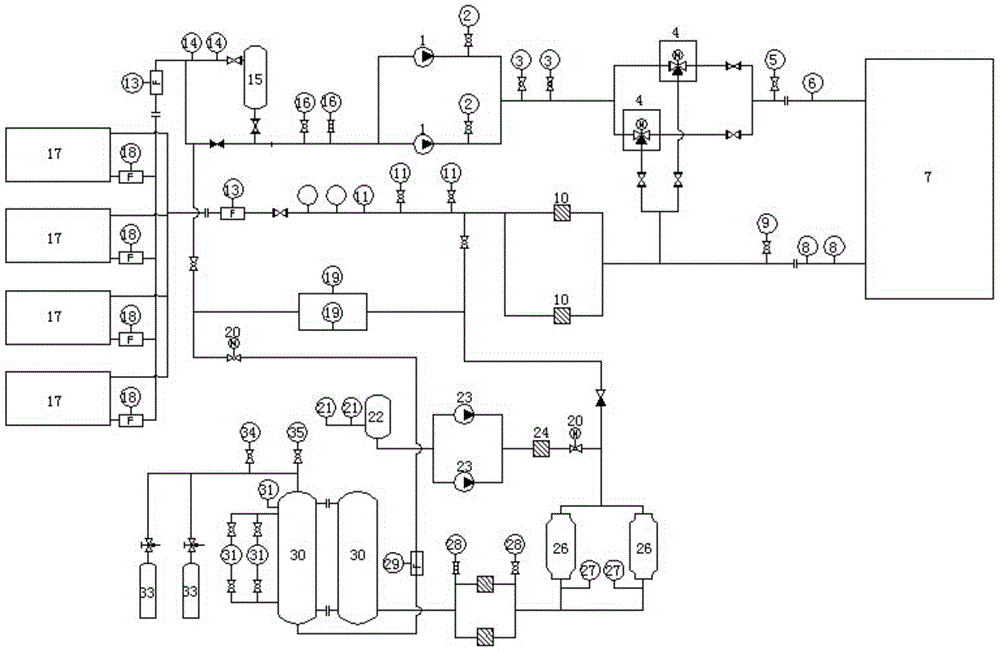

[0022] Such as figure 1 As shown, a high-voltage DC converter valve water cooling system is composed of a main circulation circuit, a deionization circuit and a water supply branch. Both are connected through electric ball valves 20, and the main circulation loop includes main circulation pump 1, closed cooling tower 7, main circulation filter 10, inlet valve temperature transmitter 11, and main circulation flow transmitter 13, which are connected in sequence through pipelines , a diverter valve group, a valve outlet temperature transmitter 14 and a degassing tank 15, an electric three-way valve 4 is also installed between the main circulation pump 1 and the closed cooling tower 7, and the diverter valve group includes a plurality of parallel groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com