Tool holder for a tool with a tool shaft provided with an outer thread

A tool holder and tool technology, used in milling cutters, reamers, manufacturing tools, etc., can solve problems such as damage accuracy, damage, and wear of guide surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

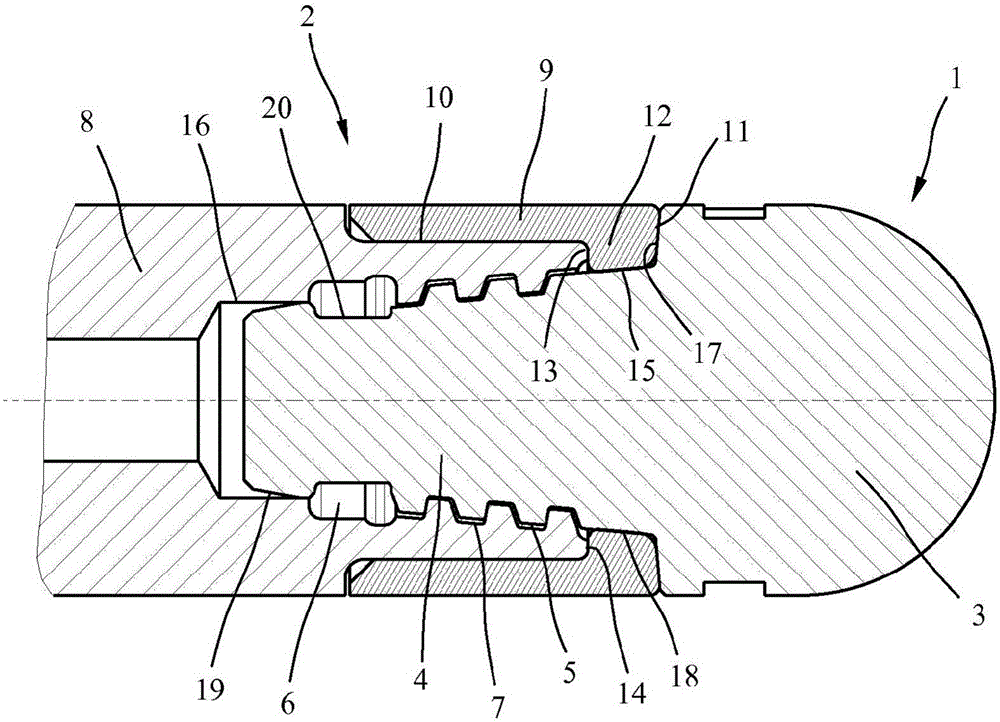

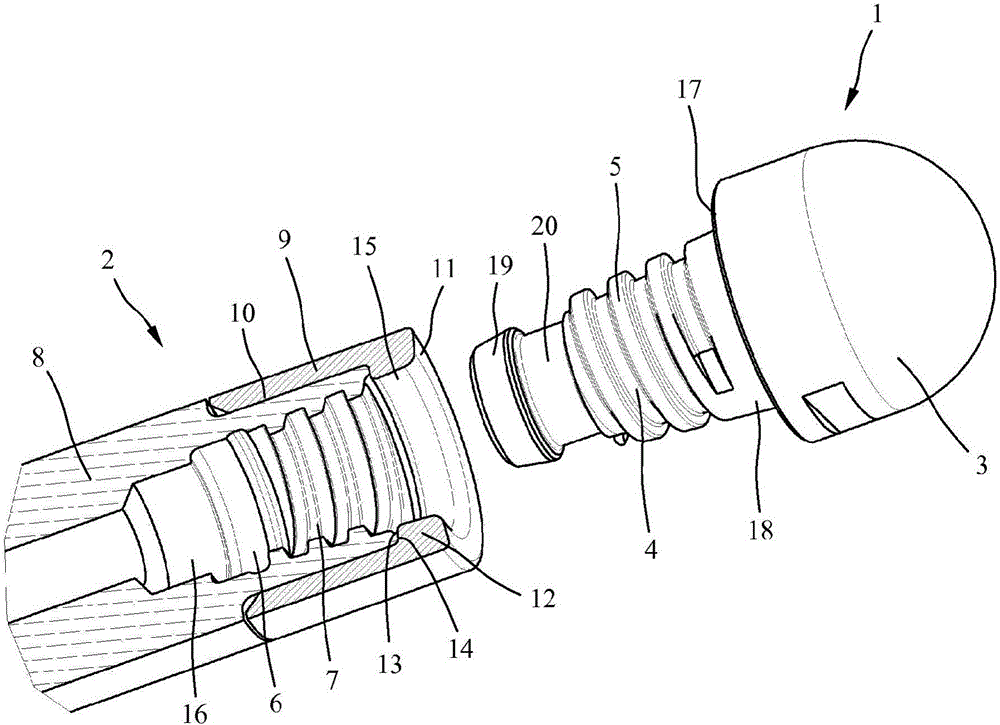

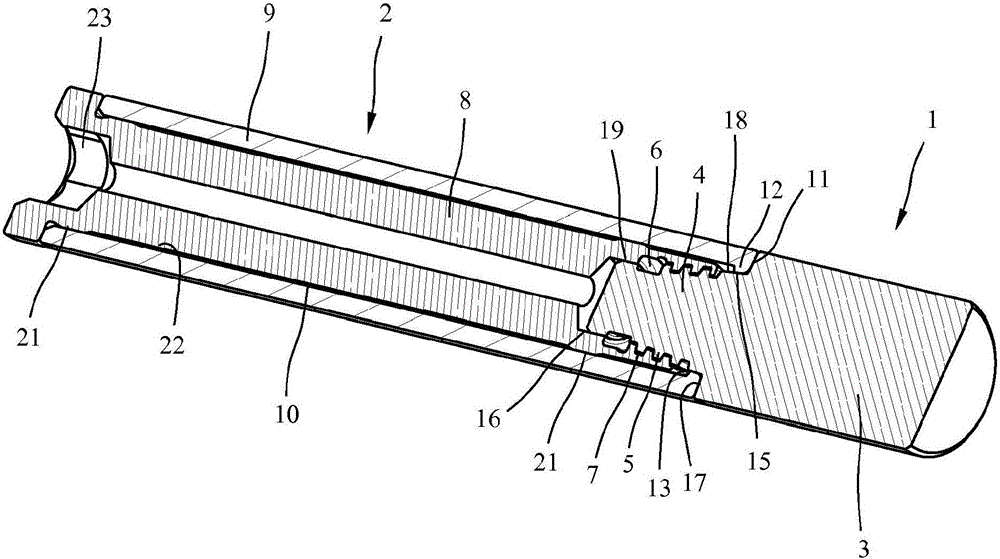

[0025] exist figure 1 and 2 shows a longitudinal section and a perspective view of a tool arrangement with a screw-in tool 1 and a corresponding tool holder 2 . In this case, the screw-in tool 1 comprises a tool head 3 designed as a ball-nose milling cutter and a tool holder 4 with an external thread 5 . The tool holder 2 assigned to the screw-in tool 1 comprises a tool holder body in which a receiving hole 6 with an internal thread 7 is provided. The internal thread 7 cooperates with the external thread 5 of the screw-in tool 1 for screwing the screw-in tool.

[0026] The tool holder body of the tool holder 2 comprises a hollow-cylindrical rear receiving part 8 and a front guide part 9 detachably fastened to the receiving part 8 . An internal thread 7 is arranged in the rear receiving part 8 . For example, a sleeve-shaped front guide part 9 can be press-fitted or shrink-fitted onto the rear receiving part 8 . The rear receiving part 8 is preferably made of hard metal, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com