Manufacturing method of replica artificial joint spacer

A technology of artificial joints and manufacturing methods, applied in joint implants, joint implants, medical science, etc., can solve problems such as patients' inability to obtain joint functions, limit clinical applications, and affect surgical effects, etc., and achieve economical and cost-effective preparation methods Ease of operation, shortened operation time, and the effect of preventing contracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

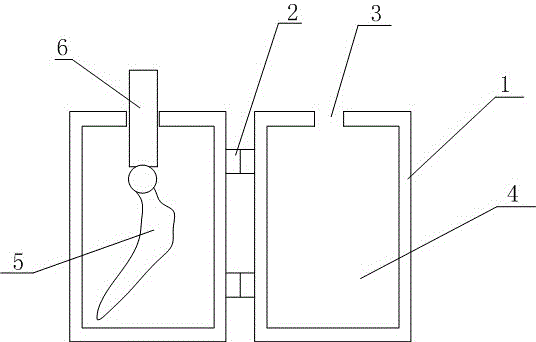

[0023] refer to figure 1 As shown, this embodiment is a box-type container for making a replica artificial joint spacer, including two completely symmetrical half-boxes 1, which are connected by two hinges 2 between the two half-boxes 1, in the box-type The top of the container offers a circular hole 3, that is, the tops of the two half-boxes 1 are respectively semicircular holes, which just become full circles after closing. Curing agent 4 is laid inside the box body, and artificial joint prosthesis 5 is placed inside the box body. After the box-type container is closed, the internal total size is greater than the size of the artificial joint prosthesis 5 to be selected, that is, the length direction of the inner space of the box-type container and the width direction are larger than the size of the artificial joint prosthesis 5 .

[0024] The manufacturing steps of using the above-mentioned box-type container to make a replica artificial joint spacer are as follows:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com