Full-automatic sidewall turn-up system of all-steel tire two-drum forming machine

A molding machine, fully automatic technology, applied in tires, other household appliances, household appliances, etc., can solve problems such as increased labor intensity, mold pollution, and increased costs, and achieve the effects of improving personnel efficiency, reducing labor intensity, and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

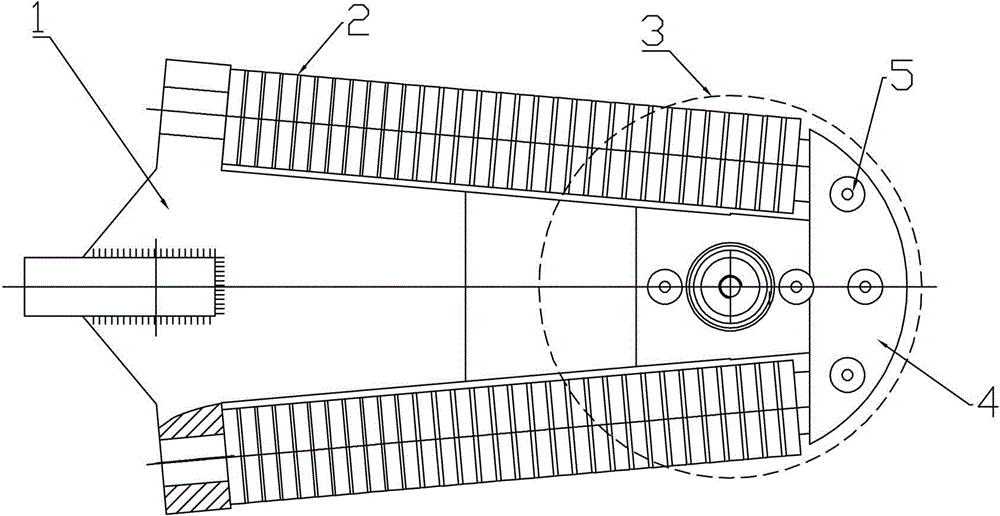

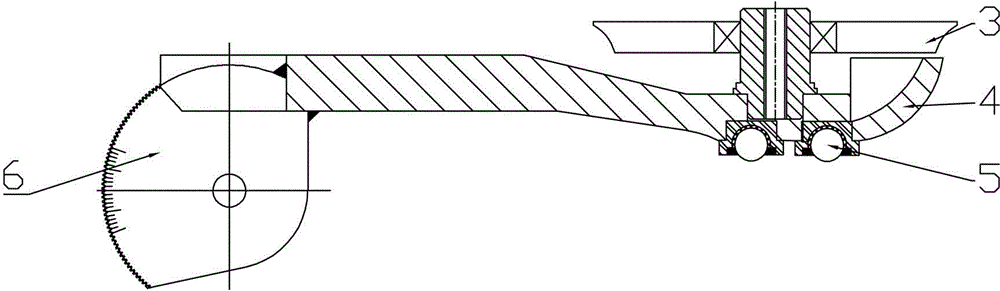

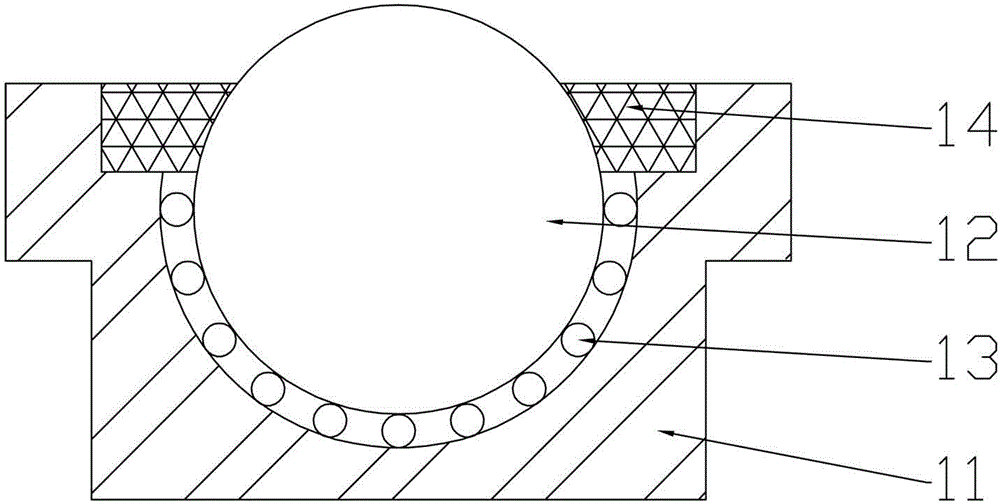

[0032] Such as figure 1 and figure 2 As shown, a full-automatic sidewall turnup system for an all-steel tire two-drum building machine is provided with conical turnup wheels 3 on both sides of the all-steel tire two-drum building machine, and the conical turnup wheels 3 pass through the sidewall turnup The wrapping arm device 10 is connected with the all-steel tire two-drum building machine; the specific structure of the sidewall turnup arm device 10 is that the conical turnup wheel 3 is arranged on the inner side of the front end of the main bracket 1 through a central bearing, and on the main bracket The front end of 1 is provided with a curved support plate 4, the curved support plate 4 is coaxial with the conical turn-up wheel 3, and the radius of the curved support plate 4 is 3-8 mm less than the radius length of the conical turn-up wheel 3; on the curved support plate 4 Several miniature universal balls 5 are provided, and the miniature universal balls 5 protrude from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com