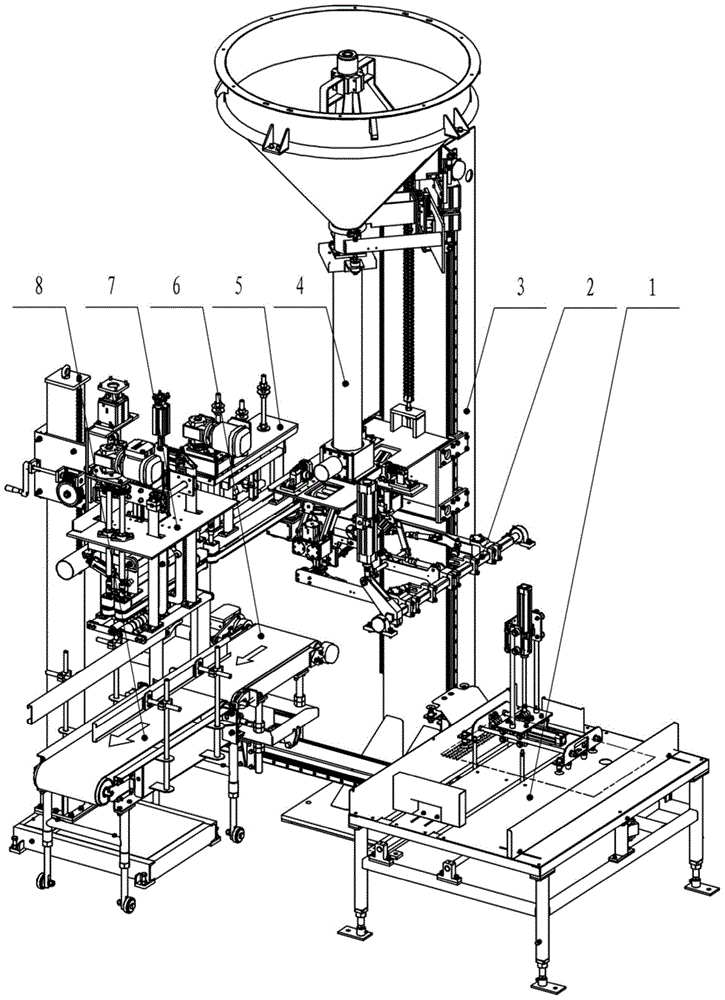

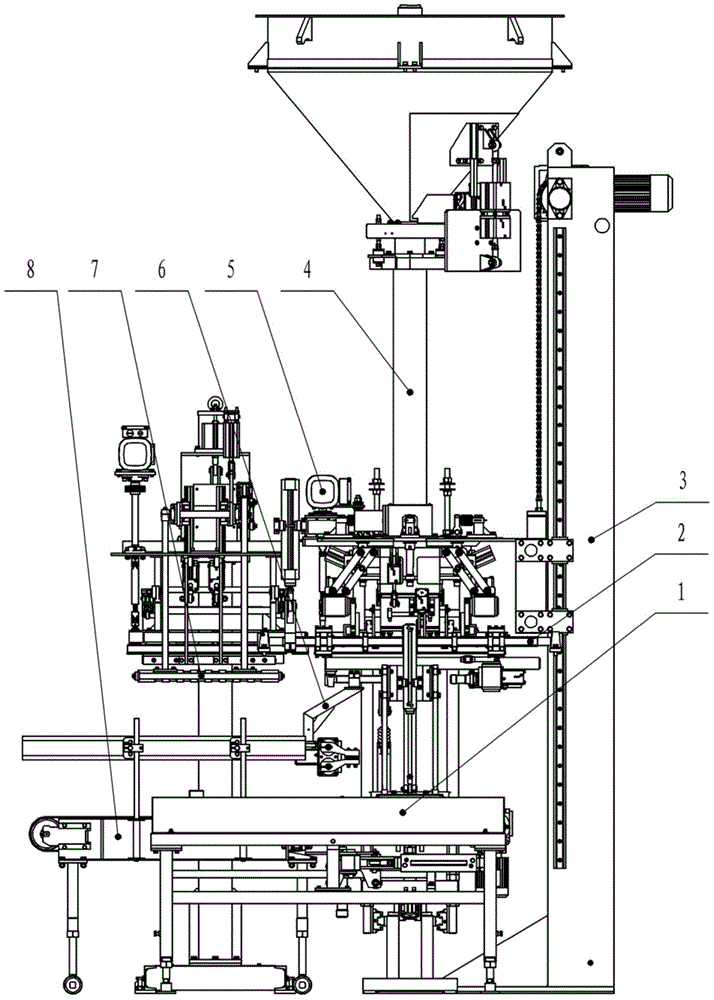

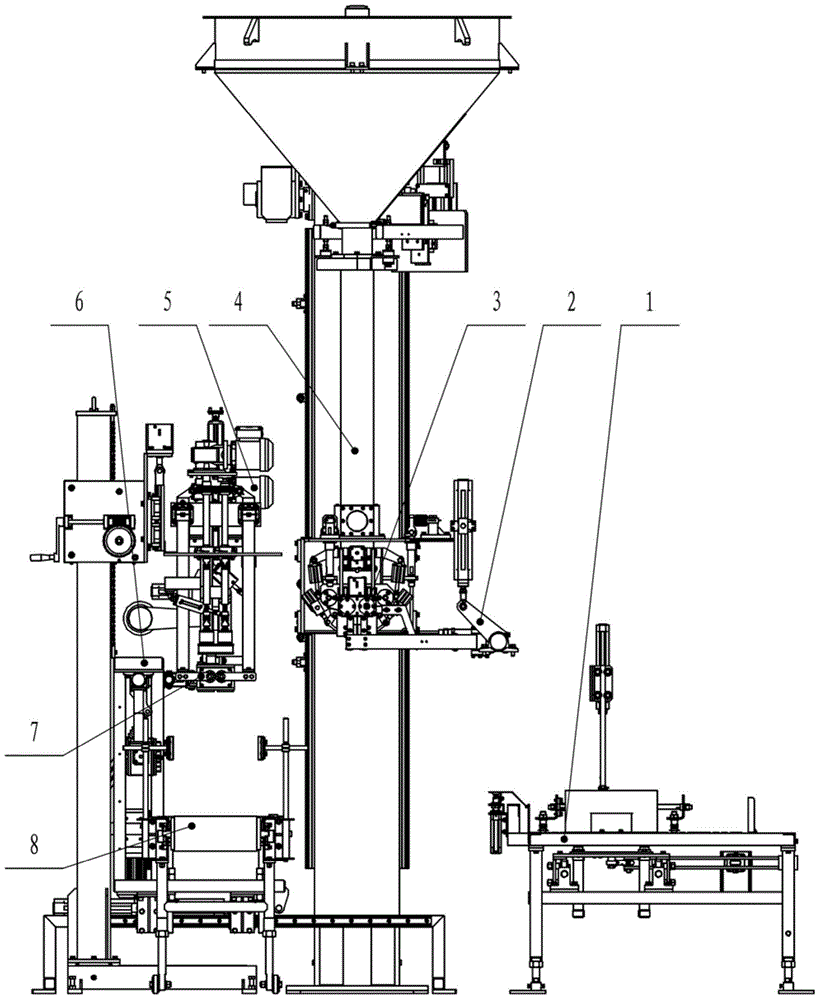

Full-automatic vertical spiral feeding packing machine

A vertical spiral and packaging machine technology, applied in the directions of packaging, transportation and packaging, packaging items, etc., can solve the problem of lack of technical solutions of automatic vertical spiral feeding packaging machine, etc., to achieve a complete packaging process, a high degree of automation, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The specific embodiment of the present invention sees Figure 1 to Figure 27 , a fully automatic vertical screw feeding packaging machine, which includes a bag feeding device 1, a bagging mechanism 2, a lifting and weighing device 3, a feeder 4, a jaw shaping machine 5, a bag moving mechanism 6, and bag mouth exhaust Device 7, vertical pouch conveyor 8, wherein the feeder 4 is located in the center of the entire packaging machine, the above-mentioned feeder 4 is an outer cylinder lifting vertical screw feeding mechanism, and the storage hopper at the upper end of the feeder 4 is equipped with a stirring mechanism , the rear of feeder 4 is provided with lifting weighing device 3, and above-mentioned lifting weighing device 3 comprises lifting column 31, and the upper end of lifting column 31 is provided with motor-driven lifting mechanism 32, and lifting mechanism 32 drives three-sensor type weighing mechanism 39 moves up and down, the bottom of the weighing mechanism 39 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com