Shuttling type vertical storeroom

A shuttle-type, vertical warehouse technology, applied in the field of warehousing and logistics equipment, can solve the problems of not being able to meet the construction requirements of a fully automatic logistics delivery system, taking a long time, and high manufacturing costs, and achieve convenient and fast delivery of goods, low manufacturing costs, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the examples do not constitute a limitation to the present invention.

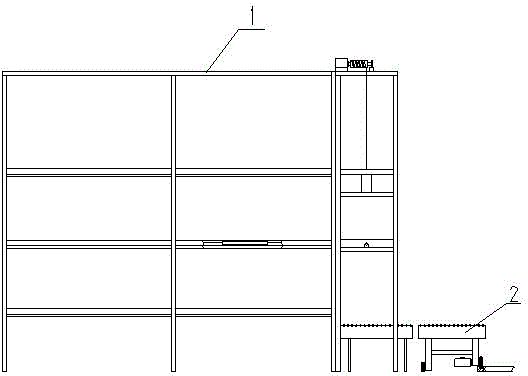

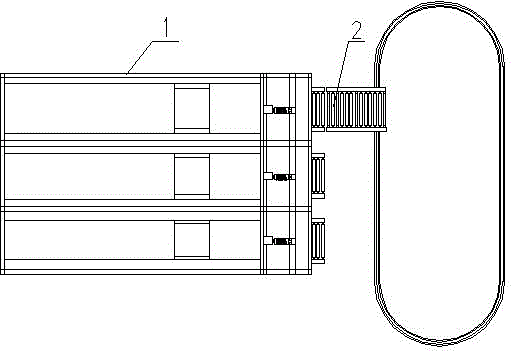

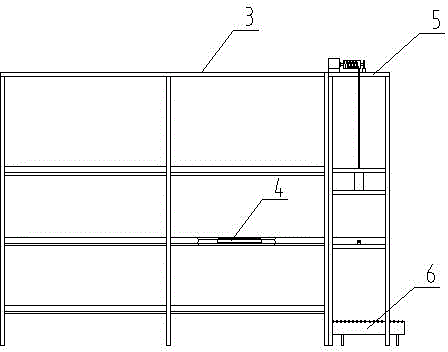

[0026] Figure 1 to Figure 7 Shown the embodiment of a kind of shuttle type vertical storage of the present invention, this shuttle type vertical storage is made up of a plurality of side by side shuttle type vertical storage units 1 and ground conveying equipment, and ground conveying equipment is ring track conveyor 2, and each shuttle Type vertical warehouse unit 1 includes a row of multi-layer penetrating storage shelves 3, shuttle cars 4, lifting equipment 5 and transfer equipment 6;

[0027] A shuttle car guide rail 9 is installed on the left side of the lifting platform 7 of the lifting device 5, and a shuttle car guide rail 10 is installed on the right side. The upper part of the shuttle car guide rail is provided with a shelf surface 13 for goods, and a stopper 14 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com