The technology of extracting lecithin from the leftovers of leather beard catfish

A technology of catfish and leftovers, applied in the field of lecithin, can solve the problems of toxic extraction solvent, no improvement, robbing food resources, etc., and achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

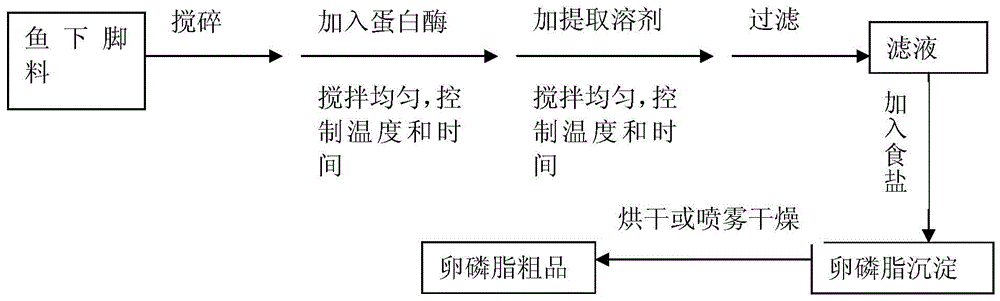

[0044]Weigh raw material 3g, adjust pH to 7, add papain (addition amount is 0.04%) to carry out enzymolysis treatment about 100min, temperature is 50 ℃, then add the mixed solvent of sodium lauryl sulfate and ethanol (dodecane Sodium sulfate is 4% addition, ethanol concentration is 33%) 30ml, extract at 35 ℃ for 60min, filter, discard the residue, then add 1g NaCl to the extract, carry out salt precipitation, salt precipitation temperature is 5 ℃, The settling time was 3 hours. After the lecithin crude product is precipitated, it is dried or spray-dried. The process flow chart is as follows: figure 1 . The minimum extraction rate of crude lecithin is about 20%, and the highest can reach about 60%, that is, 1.8 g of crude lecithin can be extracted from 3 g of raw materials at most; the purification rate is close to 90%.

Embodiment 2

[0046] Take by weighing 3g of raw materials, adjust the pH to 3, add pepsin (addition amount is 0.075%) to carry out enzymolysis treatment about 60min, temperature is 37 ℃, then add the mixed solvent of sodium lauryl sulfate and ethanol (dodecane Sodium sulfate is 6% addition, ethanol concentration is 25%) 30ml, extract at 40 ℃ for 60min, filter, discard the residue, then add 1g NaCl to the extract, carry out salt precipitation, salt precipitation temperature is 5 ℃, The settling time was 3.5 hours. After the crude lecithin is precipitated, it is dried or spray-dried.

Embodiment 3

[0048] Mince the leftovers (mainly viscera) of the catfish and mash them with a tissue masher. Weigh raw material 3g, adjust pH to 9, add trypsin (addition amount is 0.015%) and carry out enzymolysis treatment about 80min, temperature is 45 ℃, then add the mixed solvent of sodium lauryl sulfate and ethanol (dodecane Sodium sulfate is 0.67% addition, ethanol concentration is 75%) 30ml, extract 60min at 45 ℃, filter, discard residue, then add 1g NaCl in extracting solution, carry out salt precipitation, salt precipitation temperature is 5 ℃, The settling time was 4 hours. After the crude lecithin is precipitated, it is dried or spray-dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com