A circular drip irrigation maintenance system for railway thin-walled hollow pier

A thin-walled hollow pier, railway technology, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve problems such as large temperature difference between day and night, achieve flexible operation, save frequent operation, and reduce maintenance water costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

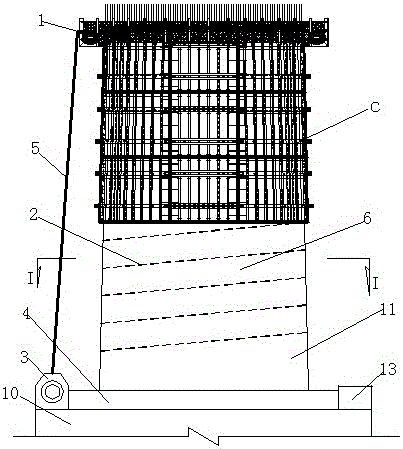

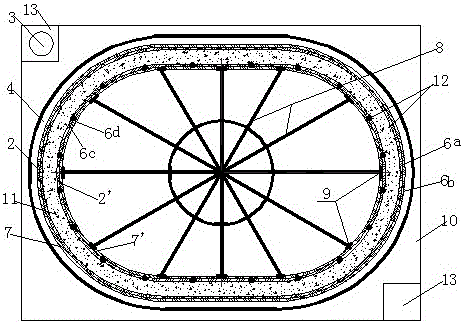

[0021] given in the present invention figure 1 , figure 2 In the embodiment of the present invention, a reservoir 4 and two sedimentation tanks 13 with a height of 1m×width of 1m×depth of 1.5m are arranged on the top of the railway thin-walled hollow pier cap 10 (around the pier body), and the sedimentation tank 13 is located in the reservoir 4, the bottom of the reservoir 4 is provided with a slope, the water in the reservoir 4 automatically flows into the two sedimentation tanks 13, and one side of the bottom of the sedimentation tank 13 is provided with a sewage valve; the two sedimentation tanks 13 are respectively A submersible pump 3 is installed, and the submersible pump 3 sends the clear water in the sedimentation tank 13 into the bucket 1 through the water pipe 5, and the start and stop of the submersible pump 3 are manually controlled.

[0022] After pouring concrete for a section of 3m railway thin-walled hollow pier, remove the inner and outer molds c, install th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com