Reusable electricity guard hanging slot group for construction of hanging basket

A technology of anti-electricity and tank body, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve problems such as easy deformation and scrapping, increase loading space, unfavorable anti-high voltage safety and reliability, etc., and achieve significant technical economy Effectiveness, guaranteed safety and reliability, reliable effect of anti-fall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The technical solution adopted by the patent for the present invention to solve its technical problems is:

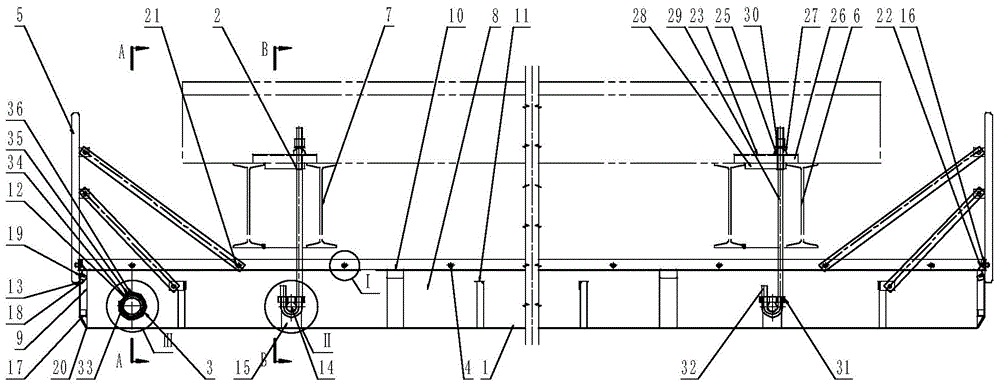

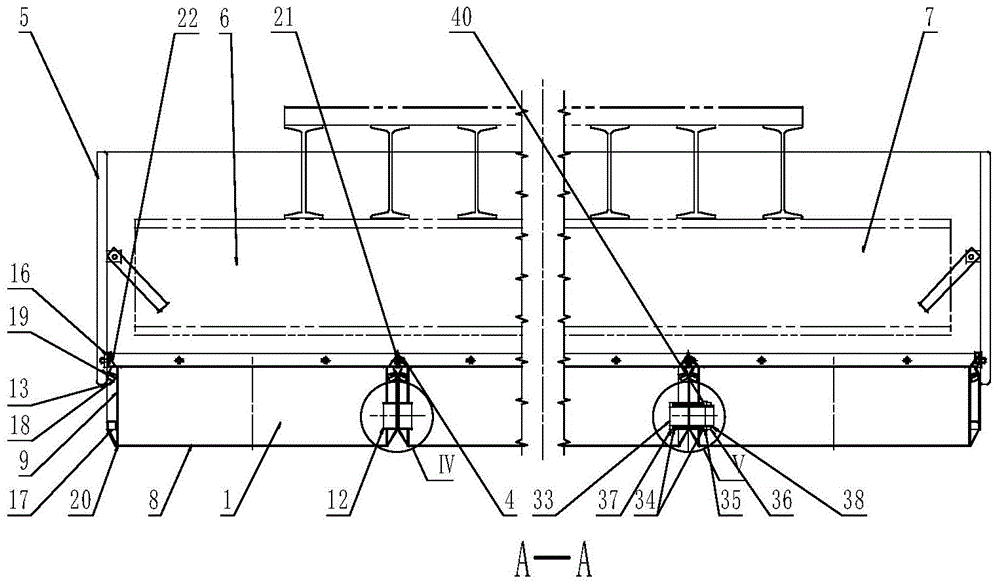

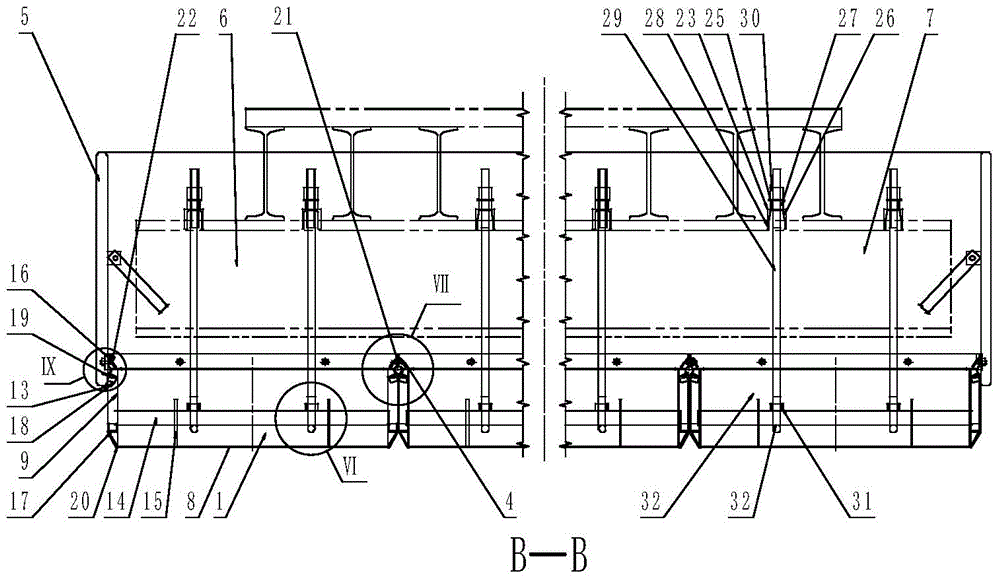

[0073] exist figure 1 , figure 2 , image 3 Among them, a reusable hanging basket construction anti-electricity hanging trough group for the protection of hanging basket construction across electrified railway overpasses, which consists of multiple anti-electricity hanging troughs (1), hinged self-locking suspension devices (2), Composed of centripetal partial pressure water connection pipe fittings (3), fasteners (4) and insulating wrapping baffles (5); hinged self-locking suspension device (2) hangs multiple anti-electricity hanging slots (1) on the hanging Below the front crossbeam (6) of the basket and the rear crossbeam (7) of the hanging basket, connect all adjacent anti-electricity hanging grooves (1) with radial partial pressure water connection pipe fittings (3), and connect adjacent ones with fasteners. The anti-electricity hanging grooves (1) are h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com