Subsection releasing downhole tool with thermodynamics partition boards

A downhole tool and thermodynamic technology, applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of oil well wax deposition, scaling, corrosion, complicated operation, poor effect, etc., and extend the pump inspection cycle , Guarantee the effect of the medicine and prolong the effect of the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

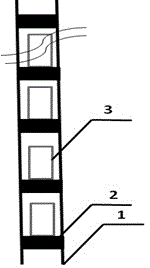

[0034] Such as figure 1 As shown, the present invention provides a segmented release downhole tool with a thermodynamic partition, which includes a working outer cylinder 1, and a plurality of thermodynamic partitions 2 are arranged at equidistant intervals from top to bottom in the working outer cylinder 1, and the thermodynamic partitions 2 is in sealing contact with the inner wall of the working outer cylinder 1 in the radial direction, and a solid chemical block 3 placed on the upper surface of the lower thermodynamic partition 2 is provided between adjacent thermodynamic partitions 2 .

[0035] After the thermodynamic partition 2 reacts with water for a certain period of time to release heat and dissolve the thermodynamic partition 2, the solid chemical block 3 loses the support of the thermodynamic partition 2, and under the action of gravity, the solid chemical block 3 falls into the bottom of the well and contacts the liquid. The slow release works its chemistry.

[0...

Embodiment 2

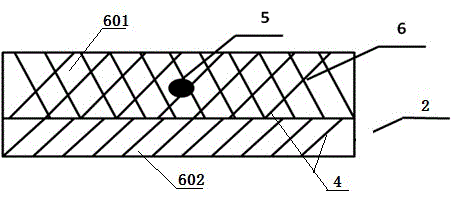

[0039] On the basis of Example 1, it should be noted that, as figure 2 As shown, the thermodynamic separator 2 is composed of a double-layer porous skeleton plate 6 and a thermodynamic erosion support 5 inside the double-layer porous skeleton plate 6 .

[0040] The thermodynamic erosion support 5 is used to support the solid chemical block 3 on the double-layer porous skeleton plate 6. After the thermodynamic separator 2 reacts with water for a certain period of time to release heat and dissolve the double-layer porous skeleton plate 6, the thermodynamic erosion support 5 contacts with water And dissolve, the solid chemical block 3 loses the supporting effect of the thermodynamic corrosion support 5, and under the action of gravity, the solid chemical block 3 falls into the bottom of the well and contacts with the liquid, and releases slowly to exert its chemical effect.

Embodiment 3

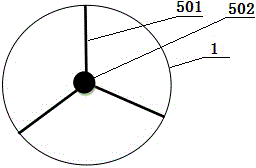

[0042] On the basis of Example 2, such as figure 2 As shown, the double-layer porous skeleton board 6 is composed of an upper porous skeleton board 601 and a lower porous skeleton board 602, the upper porous skeleton board 601 and the lower porous skeleton board 602 are connected by physical pressing or adhesive, and the upper porous skeleton board The plate 601 is composed of a network structure formed by vertically and horizontally intersecting support plates 4, the lower porous skeleton plate 602 is composed of a plurality of support plates 4 that are inclined and placed parallel to each other, and the solid chemical block 3 is placed on the upper porous skeleton plate 601. surface. Such as image 3 As shown, the thermodynamic erosion support 5 is composed of a plurality of support frames 501 and connectors 502 arranged at equal intervals, one end of each support frame 501 is fixedly connected to the connector 502, and the other end is fixed to the inner wall of the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com